Understanding the Load Capacity of Lifting Anchors: In-depth Analysis and Application Guide

In the construction and heavy lifting industries, the load capacity of lifting anchors is a critical parameter. Whether it is a towering skyscraper or an intricate bridge structure, the efficiency and safety of lifting operations depend on the load capacity of the lifting anchor. Accurate understanding and correct application of these load capacities will directly affect the safety and efficiency of the construction process. This article will focus on the load capacity of the lifting anchor in detail, deeply analyze the definition, influencing factors, types, and corresponding safety precautions of load capacity, and finally explore how to enhance the load capacity of the lifting anchor through design innovation.

Definition and Importance of Load Capacity

Introduction to Load Capacity

Load capacity refers to the maximum weight that an object or equipment can safely bear under normal working conditions. For a lifting anchor, the load capacity is not only its nominal load-bearing weight, but also the total weight it can withstand under specific circumstances, such as dynamic loads, impact loads, and extreme environments. Therefore, the load capacity should not only consider the material and design of the anchor itself, but also the load capacity of the entire system to ensure safety.

Importance of Load Capacity

In construction and lifting operations, the definition and understanding of load capacity are crucial. Whether it is building construction, bridge construction, or other heavy engineering projects, lifting operations need to ensure safety based on the load capacity of the lifting anchor. If the load capacity is underestimated or misused, it can lead to serious safety hazards and even catastrophic consequences such as equipment damage, loss of life, etc. Because of this, understanding the nuances of load capacity and selecting the right lifting anchor is key to ensuring safe operations.

Basics of Load Capacity

Load Capacity of Lifting Anchors Explained

The load capacity of a lifting anchor is not fixed and is affected by a variety of factors. The following are the main factors that affect the load capacity of a lifting anchor:

Material Strength:

Lifting anchors are usually made of high-strength steel, but different grades of steel have different mechanical properties such as tensile strength, yield strength, and ductility. The quality and strength grade of the steel directly affects the load capacity of the lifting anchor.

Anchor Design:

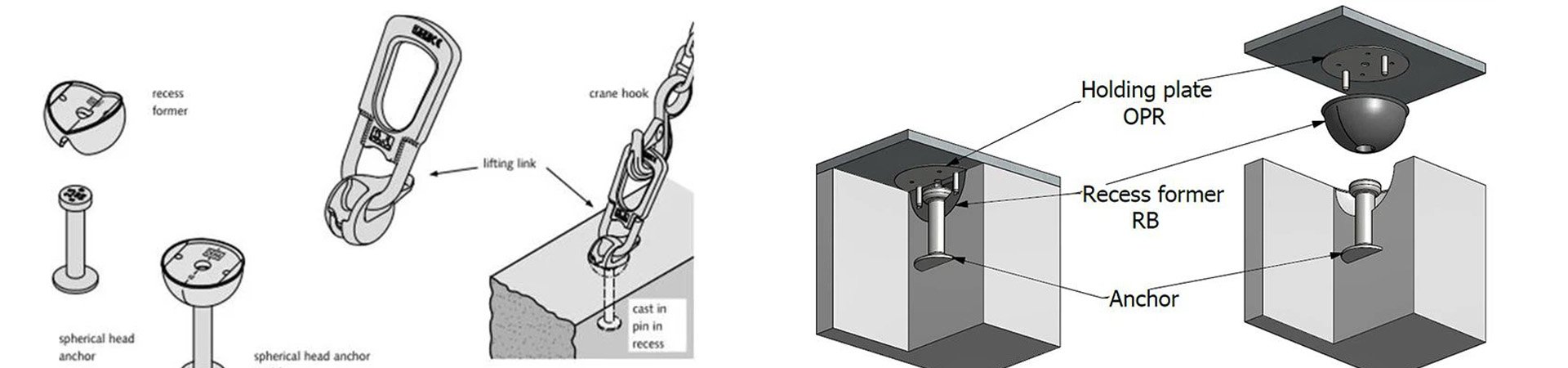

The design and geometry also affect the load capacity. Different designs such as ball anchors, stud anchors, and universal anchors have different load distribution patterns and are suitable for different working scenarios.

Manufacturing process:

Precision and process control during the manufacturing process also affect the performance of the anchor. Modern manufacturing processes such as heat treatment and surface treatment help improve the fatigue resistance and corrosion resistance of the material, thereby enhancing the load capacity.

Working conditions:

External environmental factors such as temperature, humidity, and wind speed have a direct impact on the performance of the anchor. Extreme conditions such as low-temperature brittleness and high-temperature softening will weaken the load capacity of the anchor.

Factors affecting load capacity

The load capacity of the lifting anchor is affected by many variables, and common influencing factors include:

Anchor size:

The size of the anchor (diameter, length, width, etc.) directly determines its load capacity. Generally, the larger the size, the stronger the load capacity.

Shape design:

Different shapes affect the stress distribution of the anchor when it is subjected to force. For example, due to different geometric shapes, the load distribution of ball anchors and stud anchors is different, which affects the final load capacity.

Support material:

Lifting anchors are usually connected to concrete or steel structures. The nature of the supporting material, such as the strength grade of the concrete or the quality of the steel, also affects the overall load capacity of the anchor system.

Installation Method:

Proper installation methods are crucial. If not installed properly, even anchors with high load capacity may fail due to uneven loads or loose installation.

Types of Lifting Anchors

Overview of Different Types

There are many different types of Lifting Anchors, each with different designs, functions, and load-bearing capacities. Here are some of the most common types:

Spherical Head Anchor:

Anchors with a ball head design help to spread the load and are suitable for carrying heavier loads.

Spherical Double Headed Lifting Anchors:

This design increases the number of anchor points, allowing it to withstand higher loads, and is suitable for large buildings and bridge construction.

Lifting Eye Anchor:

Anchors with eyelets are often used for light lifting operations and are suitable for repeated use.

Utility Anchor:

This multi-purpose anchor is suitable for a wide range of applications and performs well in tasks ranging from light to medium loads.

Differences in load capacity between different types

Each type of Lifting Anchor has a different load capacity. It is important for professional construction personnel to understand these differences:

Ball anchors usually have a larger contact surface, which is conducive to dispersing forces and is suitable for heavy load-bearing tasks.

Double-headed ball anchors enhance the load capacity by increasing the contact points and distributing the load, which is particularly suitable for lifting large components.

The ring anchor is suitable for light load occasions due to its simple design, but it is very practical in applications where flexible adjustment of the lifting position is required.

General anchors provide flexibility and are suitable for a variety of loads, but in some cases, their load capacity may not be as good as specially designed anchors.

Safety precautions

The importance of strictly adhering to load capacity limits

When using a Lifting Anchor, it is crucial to strictly adhere to its rated load capacity. Overloading will expose the anchoring system to higher stresses, causing premature material failure, deformation, or even fracture. More importantly, overloading will not only damage the equipment but also endanger personnel safety. Therefore, during operation, accurate load calculations and reasonable operating steps should be used to ensure that the load capacity is not exceeded.

Consequences of Exceeding the Load Capacity

Exceeding the load capacity of the Lifting Anchor may lead to serious consequences. Common consequences include:

Anchor failure:

When the load exceeds the design load limit, the anchor may break or deform, causing the lifting object to lose support.

Equipment damage:

Overloading will cause additional stress to the lifting equipment. Under long-term use, the life of the equipment may be significantly shortened, or even fail at a critical moment.

Safety hazards:

The most serious consequence is the threat to construction personnel. The failure of the anchor will cause the heavy objects to fall, endangering the lives of on-site personnel.

Strategies to enhance load capacity

Strategies to improve the performance of the Lifting Anchor

To improve the load capacity of the lifting anchor, improvements can be made in many aspects:

Material selection:

By selecting higher-strength materials, such as high-performance alloy steel, the load capacity of the lifting anchor can be significantly improved.

Surface treatment:

Enhancing the corrosion resistance of the anchor, especially in humid or marine environments, using hot-dip galvanizing or coating treatment can effectively extend the service life of the equipment.

Optimized geometric design:

The load capacity of the lifting anchor can be improved by optimizing the design, such as increasing the contact area of the anchor or enhancing the load distribution.

Anchor design innovation to improve load-bearing capacity

Design innovation is an important area in improving load capacity. By improving the geometric design and manufacturing process of the anchor, its performance in actual operation can be significantly improved. Here are some examples of design innovation:

Application of composite materials:

By adding high-performance composite materials to the steel anchor, the weight of the anchor can be reduced while improving its load capacity and fatigue resistance.

Modular design:

The modular design allows multiple anchors to be combined together to form an integrated system, thereby sharing the load and improving the overall load-bearing capacity.

Optimized design for dynamic loads:

For dynamic load scenarios (such as vibration and impact during lifting), the load-bearing capacity of the lifting anchor under complex working conditions can be effectively enhanced by optimizing the structural design and material combination.

HULK Metal's lifting anchors are strictly sampled and tested before leaving the factory. The testing process covers multiple indicators such as tensile strength, corrosion resistance, and fatigue testing to ensure the safety and reliability of the product under various complex working conditions. Ensure that every product delivered to you is 100% qualified.

Why choose HULK Metal as your Lifting Anchor supplier?

Quality, safety, and reliability are key factors when choosing a Lifting Anchor supplier, and HULK Metal is the ideal partner to meet these high standards. Here are a few important reasons to choose HULK Metal as your Lifting Anchor supplier:

Multiple International Quality Certifications

HULK Metal strictly adheres to international quality management standards and has passed ISO 9001 certification. This shows that we have ensured a high standard of quality management system in all aspects of product design, production, and service. At the same time, we have also obtained ISO 45001 occupational health and safety management system certification, which reflects our high attention to employee safety and product safety. As a green enterprise, HULK Metal has also passed ISO 14001 environmental management system certification to ensure that sustainable development measures are taken during the production process to reduce the impact on the environment. These certifications show that we not only pay attention to product quality but also care about the safety of employees and the protection of the global environment.

CE Certification, Compliant with European Market Standards

HULK Metal's building accessories have long been CE certified, which means that our Lifting Anchor fully complies with the EU's safety, health, and environmental requirements. For customers who need to sell their products to the European market, CE certification is vital quality assurance. This allows our customers to use our products with confidence in multiple international markets and ensure that they meet the most stringent safety standards when applied to various engineering projects.

Advanced QC Center

We have a first-class quality control center equipped with advanced testing equipment and a professional technical team to conduct strict quality inspections on each batch of products shipped out of the factory. HULK Metal ensures that all Lifting Anchor products meet or even exceed the requirements of industry standards by tracking every link from raw material procurement to production, testing, and delivery. We not only conduct physical tests but also carry out comprehensive performance testing and safety assessments to ensure the strength, durability, and reliability of the products and minimize any potential safety risks.

Through a deep understanding of load capacity and technological innovation, the application of Lifting anchors in the construction and heavy lifting fields will become safer and more efficient, promoting the development of the industry. If you need to purchase lifting anchors, please contact us immediately.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.Spherical Head Lifting Anchor: In-depth discussion of materials, production processes, quality inspection procedures and supplier selection guide

- 2.A comprehensive introduction to Lifting Anchor

- 3.How to Choose High-Quality Shuttering Magnetic Products and Suppliers Guide

- 4.Applications and advantages of swivel hoist rings: HULK Metal provides you with safer and more flexible lifting solutions

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.