Applications and advantages of swivel hoist rings: HULK Metal provides you with safer and more flexible lifting solutions

Application Scenarios of Swivel Hoist Ring

With the rapid development of the mold industry, swivel hoist rings have been widely used in the market, especially in mold factories, construction units, and machinery manufacturing industries. In addition, the rise of the wind power industry has a particularly strong demand for the swivel hoist ring. These application areas require higher safety and flexibility in hoisting equipment, and swivel hoist rings are the ideal choice for this design.

Advantages of Swivel Hoist Ring

Traditional DIN 580 hoisting ring screws can only be vertically hoisted at 0 degrees. When the hoisting angle exceeds 45 degrees, its strength loss is as high as 70%; and in the case of 90-degree hoisting, its strength loss can even reach 75% (according to GB825 and DIN 580 standards). In the current environment where hoisting safety is increasingly valued, this limitation has led to the inapplicability of traditional hoist rings in many application scenarios. In contrast, swivel hoist rings have gradually replaced traditional DIN 580 hoist rings with their superior flexibility, safety, and durability, and have been used in a wider range of hoisting fields.

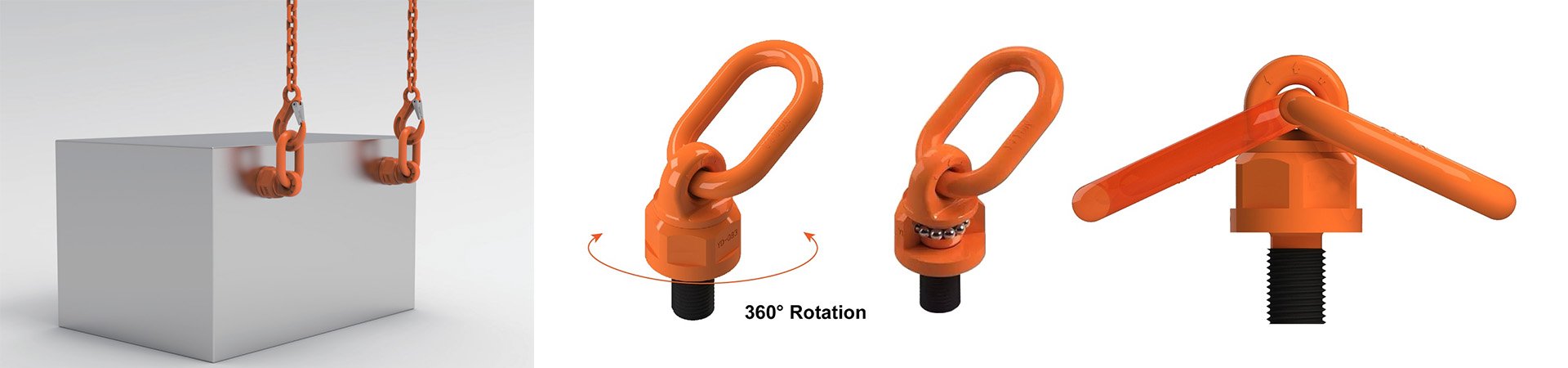

The Swivel Hoist Ring produced by HULK Metal adopts a ball-bearing design suitable for rotation and heavy-load rotation. It can achieve 360-degree rotation under load and can achieve 180-degree flipping movement with the shaft as the fulcrum. The bearing design of the swivel hoist ring meets high safety requirements with a safety factor of 4 times; the manufacturing of the hoist eye parts meets the DIN EN 1677-4 standard, and all products pass 100% crack detection and verification load tests to ensure high quality and high safety. In addition, the surface of the product is specially plated with crown anti-corrosion treatment to enhance its durability and corrosion resistance.

Characteristics of HULK Metal Swivel Hoist Ring

Material advantages:

The main material of the swivel hoist ring is made of high-quality 42CrMo alloy steel, which has better toughness and fatigue resistance than similar domestic products. This high-strength material can withstand repeated heavy-load lifting without breaking or deformation.

High-strength bolts:

Using 12.9-grade high-strength bolts with 6G thread accuracy and blackened anti-rust treatment, it ensures durability and safety in various extreme working environments. In addition, all threads are strictly inspected to ensure that they meet the standards of use.

Standardized production:

All products are strictly produced in accordance with EN 1677 standards to ensure their universality and safety worldwide.

High load capacity:

The swivel hoist ring has a 4-fold working load capacity and has successfully passed 20,000 fatigue tests, which fully demonstrates its excellent reliability and service life.

Strengthened testing:

The swivel hoist ring has undergone two experimental loads and four breaking tensile tests to ensure that it can maintain stable performance and structural integrity under extreme conditions.

Magnetic particle inspection:

Each swivel hoist ring is 100% magnetic particle inspected. This non-destructive testing method can identify tiny cracks and defects inside the product, thereby ensuring the high quality of the product.

Customized service:

According to the different needs of customers, HULK Metal can provide customized thread solutions to meet the requirements of various specific application scenarios.

Diversified applications of swivel rings

In the wind power industry, swivel hoist rings are used for the installation and maintenance of large wind power equipment, which can ensure the safety of hoisting during high-altitude operations. In the mold manufacturing industry, swivel hoist rings are used to transport large and complex molds, providing reliable safety and ease of operation. In construction units, swivel hoist rings are used for the installation of various steel structures and equipment, which can effectively reduce the risk of damage to equipment due to lifting angles. In addition, in the field of mechanical manufacturing, swivel hoist rings are widely used for the handling and assembly of heavy parts.

Significant advantages over traditional rings

Compared with traditional DIN 580 rings, HULK Metal's swivel hoist ring design pays more attention to safety and operational flexibility. Its advanced ball bearing design and high-quality material selection make the swivel hoist ring more adaptable in various complex lifting operations. Its surface anti-corrosion treatment can be used for a long time in harsh environments such as marine environments and chemical plants without corrosion. Each swivel hoist ring undergoes strict quality control and multiple tests to ensure its excellent performance in various application scenarios.

HULK Metal's manufacturing process and quality control

HULK Metal's factory uses advanced manufacturing equipment and production processes. All swivel hoist rings are processed and formed on precision CNC machine tools to ensure high precision and high consistency of the products. The factory has a strict quality inspection system. From raw material procurement, production, and manufacturing to the final product delivery, every link is strictly controlled by professionals. In addition, the factory has passed the ISO 9001 quality management system certification to ensure that customers are provided with the highest standard of products and services.

As key lifting equipment, the swivel hoist ring is rapidly replacing the traditional ring with its excellent performance and high safety, becoming the preferred product in modern industrial applications. HULK Metal has always been committed to technological innovation and quality improvement to provide global customers with safer, more reliable, and efficient lifting solutions. Whether it is conventional use or special applications, HULK Metal's swivel hoist ring can meet various needs and help customers achieve higher efficiency and safety standards in their respective industries.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.