Concrete Screws:Which Type Should You Use?

Concrete screws, like wood screws for wood, provide a quick and easy way to fix concrete while having a strong load-bearing capacity. They are a convenient installation method that screws directly into concrete and, unlike traditional installation methods, does not require any hammering. Simply drill a hole, clean it, and screw the screw in.

These screws have a serrated cutting thread that cuts into the concrete as it is screwed in, providing a tight and secure fix. Concrete screws can be used not only in concrete, but also in materials such as solid brick, hollow brick, and stone. Click on the concrete screws to learn The following will introduce the types of these screws and their performance characteristics in practical applications in detail.

Considerations when choosing concrete screws

When choosing concrete screws, consider the type of loads to be carried and their load capacity. Different types of loads describe forces of different directions and nature acting on an object. When choosing the right screw, you need to compare the load type and capacity of the anchor with the weight and possible movement of the object to be fixed.

- Shear load: The downward force exerted on the anchor by the weight of the object.

- Tensile load: The force that pulls the anchor directly out of the hole.

- Static load: generated by an object that never moves and continuously applies the same force.

- Dynamic load: generated by an object that moves or vibrates.

- Impact load: force generated by a sudden increase in weight.

Types of concrete screws

Depending on the specific application requirements, concrete screws with different head shapes and materials can be selected:

- Hexagon head screw: provides greater torque and is suitable for heavy-duty fixation.

- Flat head screw: suitable for installation scenarios that require a flat surface.

- Conical head screw: suitable for embedded installation, providing a more beautiful appearance.

Typical application scenarios

Concrete screws are widely used in various construction and installation projects, mainly including the following aspects:

- Ventilation system: In the installation of ventilation systems, concrete screws can provide stable and secure fixation to ensure the reliable operation of pipes and equipment.

- Sanitary facilities: The installation of sanitary facilities such as toilets, wash basins, etc. requires firm fixation, and concrete screws can meet this demand.

- Electrical installation: In electrical installation, wire pipes and equipment need to be securely fixed, and concrete screws are an ideal choice.

- Fixing tracks: Whether it is industrial tracks or household slides, concrete screws can provide a stable fixation.

- Cable tray: The installation of cable trays requires reliable fixation to support the weight of the cables, and concrete screws can ensure the safety of installation.

- Steel structure attachment: In steel structure buildings, concrete screws are used to fix support and connection components to ensure the stability of the overall structure.

- Fences and supports: Whether it is outdoor fences or indoor support structures, concrete screws can provide a reliable fixation.

- Clamps and brackets: Used to fix various equipment and tools, concrete screws can ensure their stability.

Installation steps

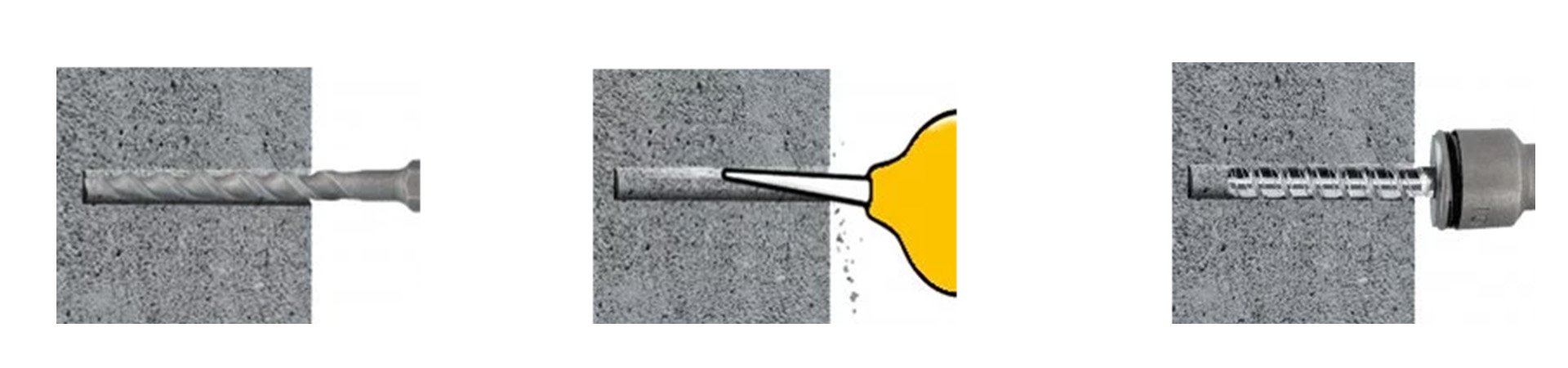

Step 1: Drilling

Use a drill bit of appropriate size to drill holes in the concrete, ensuring that the depth and diameter of the holes match the specifications of the screws.

Step 2: Clean the holes

Use an air pump or cleaning tool to clean the dust and debris in the holes to ensure that the screws can be screwed in smoothly.

Step 3: Screw in the screws

Align the concrete screws with the holes and screw them in with an electric screwdriver or hand tool until the screw head is flush with the concrete surface.

Installation precautions

- Protective measures when drilling: During drilling and installation, wear appropriate protective equipment, such as goggles and gloves, to avoid damage from debris.

- Hole cleaning: Make sure the holes are thoroughly cleaned to avoid affecting the fixing effect of the screws.

- Screw selection: Select screws of appropriate specifications and materials according to specific load requirements to ensure their load-bearing capacity and durability.

How To Choosing A Concrete Screws Supplier

As a professional manufacturer of concrete screws, we offer a variety of high-quality products suitable for different applications. Most of HULK Metal's screws have undergone extensive testing and have received European Technical Approval (ETA), including fire resistance tests, to ensure compliance with the stringent quality and safety standards of the European market. Additionally, some of our screws come with seismic options. Please refer to the technical data of each screw for detailed information.

Concrete screws are an efficient and reliable fixing solution suitable for a variety of construction and installation needs. By correctly selecting and installing concrete screws, you can ensure the stability and safety of the structure and improve the overall quality and life of the project.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.Lifting Socket: Types and Selection Guide

- 2.Lifting Anchors: An Essential Component in Construction and Heavy Lifting

- 3.A 20-year-old factory tells you about application and manufacturing of precast concrete lifting clutch

- 4.How to detect Lifting Points to make the lifting environment safe?

- 5.How to choose a high-quality hoist ring?

- 6.An old engineer who has retired for ten years tells you the safe use of precast concrete lifting clutches

- 7.Factory tells you how to choose suitable spherical head anchors?

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.