Understanding Load Capacity: A Guide to Lifting Anchor Strength

In the construction and heavy lifting fields, it is critical to understand the load capacity of a lifting anchor. As a key connector, the lifting anchor is responsible for transferring weight from the lifting equipment to the object being lifted. Whether used for the handling of building components or the lifting of equipment, the safe use of these lifting anchors depends on the correct understanding and use of their load capacity.Click on the link to learn more about our products.

Definition of Lifting Anchor Load Capacity

The load capacity of a lifting anchor generally refers to the maximum tension or load that the anchor can withstand under specific conditions of use. It is affected by a variety of factors, including but not limited to the design and manufacturing process of the anchor, the physical properties of the material, the installation method, the use environment, etc. Different types of lifting anchors, such as bolt-type anchors, expansion anchors, and mechanical anchors, may have different load capacity standards and calculation methods.

Design Safety Factor

Load capacity is usually expressed in terms of rated load and design safety factor. The design safety factor is a factor set to ensure safety, usually between 2 and 4, depending on the application scenario and regulatory requirements. This means that in actual use, the load carried by the Lifting Anchor should be less than one-half to one-quarter of its rated load.

Material Strength

The load capacity of the Lifting Anchor is also directly related to the strength of its material. Common materials such as carbon steel, alloy steel, stainless steel, etc., have different effects on load capacity due to their different strength, ductility, and corrosion resistance. For example, high-strength steel is usually used in situations requiring higher load capacity, while stainless steel is suitable for use in corrosive environments.

Factors Affecting the Load Capacity of the Lifting Anchor

Design and Shape of Anchors

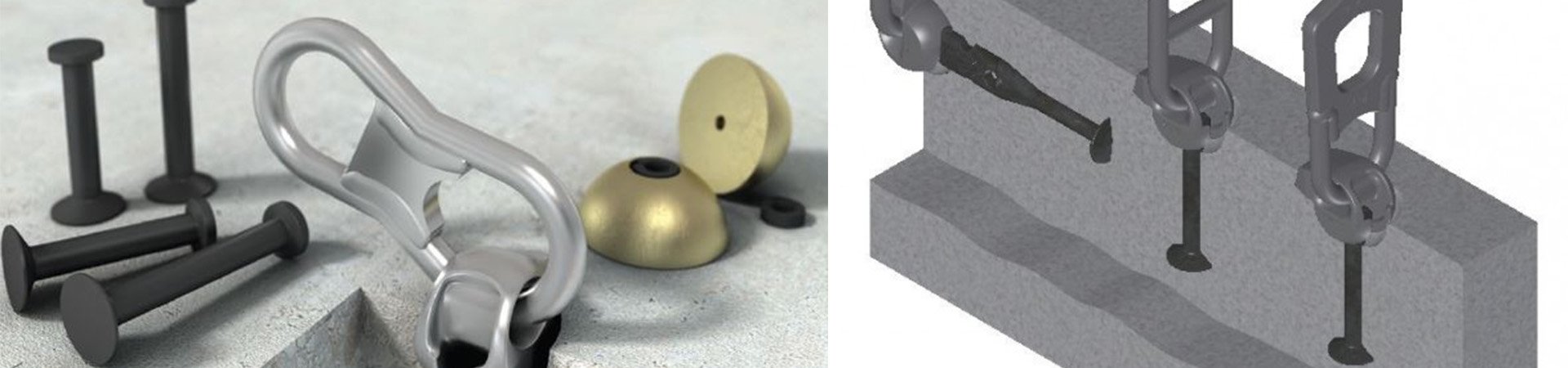

Different design shapes such as straight shank, eye, U-shaped, etc. have different stress distribution characteristics. These design differences affect the performance of the anchor when carrying loads. For example, eye-shaped anchors are more suitable for multi-directional tension, while straight shank anchors perform better under pure tension conditions.

Installation Method

The installation method has a significant impact on the load capacity of the Lifting Anchor. The embedment depth, installation angle and fastening method will affect its load capacity. Installing too shallow or at an incorrect angle will cause the anchor to fail to fully exert its design strength. In addition, the construction quality during the installation process is also one of the factors that influence the cleanliness and dimensional accuracy of the mounting holes.

Use environment

Environmental factors such as temperature, humidity, corrosive media, etc. will also affect the load capacity of anchors. High temperature environment will cause the material strength to decrease, while humid or corrosive environment may accelerate the corrosion of the material, thereby reducing its load capacity. Under these conditions, it is particularly important to choose the right material and surface treatment process.

How to choose the lifting anchor correctly

Determine the load requirements

When choosing a suitable lifting anchor, you must first clarify the load requirements of the use scenario, including the maximum static load and dynamic load. You need to select the appropriate anchor according to the load type, such as fixed load, dynamic load or impact load.

Consider material and environmental factors

Select appropriate materials and surface treatment according to the specific conditions of the use environment (such as temperature, humidity, and corrosiveness). For example, in a marine environment, stainless steel anchors with higher corrosion resistance should be selected, and special coating protection may be required.

Calculate the design safety factor

When determining the load capacity of the anchor, you need to calculate the appropriate design safety factor according to the engineering requirements. This factor is the key to ensure that the Lifting Anchor can still operate safely under extreme conditions. In some high-risk situations, such as heavy equipment lifting or high-altitude operations, the safety factor should be higher.

Testing and verification of Lifting Anchor

Laboratory testing

Before actual use, the Lifting Anchor needs to undergo rigorous laboratory testing to verify its load capacity and safety performance. These tests usually include tension tests, fatigue tests, impact tests, etc. to ensure the reliability of the anchor under different stress conditions.

Field verification

The Lifting Anchor after laboratory testing must also be verified on-site, especially when used in a specific construction environment. Field verification can more realistically reflect the performance of the anchor under actual conditions and ensure the correctness of the installation and the reliability of the load capacity.

Quality control and monitoring

During use, the Lifting Anchor should be regularly inspected and maintained, especially under high-frequency use or extreme conditions. Inspection methods include visual inspection, ultrasonic testing, magnetic particle inspection, etc. to ensure that the anchor has no cracks, corrosion, or other defects.

Maintenance and Replacement of Lifting Anchor

Regular Maintenance

In order to ensure the long-term safety and stable performance of the Lifting Anchor, regular maintenance and inspection are required. Inspections should include thread status, anchor position, surface condition, etc. Any damage or wear that may affect the load capacity should be immediately handled or replaced.

Replacement Conditions

If the Lifting Anchor is found to have cracks, bends, severe corrosion, or other structural damage, it should be stopped and replaced immediately. In addition, after exceeding the design service life, even if there is no obvious damage, replacement should be considered to ensure safety.

Storage and Protection

Unused Lifting Anchors should be stored in a dry, well-ventilated environment to avoid contact with corrosive substances. If necessary, take anti-rust measures such as applying anti-rust oil or using a protective cover to extend its service life.

Importance of Selecting a Qualified Supplier

Selecting a qualified and experienced Lifting Anchor supplier is crucial to the success and safety of the project. HULK Metal has international certifications such as ISO 9001 to ensure that its quality control during the production process meets international standards. In addition, we can provide detailed product inspection reports, quality assurance, and technical support services to ensure the reliability and applicability of the product.

Understanding and mastering the load capacity of the Lifting Anchor is not only a basic requirement for engineering design but also an important measure to ensure construction safety and improve engineering efficiency. Correct selection, installation, testing, and maintenance of the Lifting Anchor will minimize the risk of accidents and provide solid protection for construction and heavy lifting work. Every engineer and operator should have a basic understanding of the load capacity of the Lifting Anchor and strictly follow relevant standards and specifications in actual operation to ensure the safety and reliability of the work.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.