Uses of various lifting anchors

Definition of Lifting Anchor

Lifting Anchor is an anchoring device specially used for lifting operations of precast concrete components (such as wall panels, beams, columns, piles, etc.). Lifting anchors are usually embedded in concrete components to form a reliable anchoring point for lifting equipment to connect to components through slings or hooks to complete lifting and handling work safely and quickly. Lifting anchor systems are widely used in buildings, bridges, precast structures, and other fields, which can effectively improve construction efficiency and ensure the safety and accuracy of operations.

Classification of lifting anchor

The lifting anchor system usually consists of a lifting anchor, a hook (or a sling), and related accessories. According to different load requirements, component shapes, and usage scenarios, lifting anchors can be divided into many types, mainly including spherical head anchors, Lifting Eye Anchor, Spherical Double Headed Lifting Anchor, and Utility Anchor.

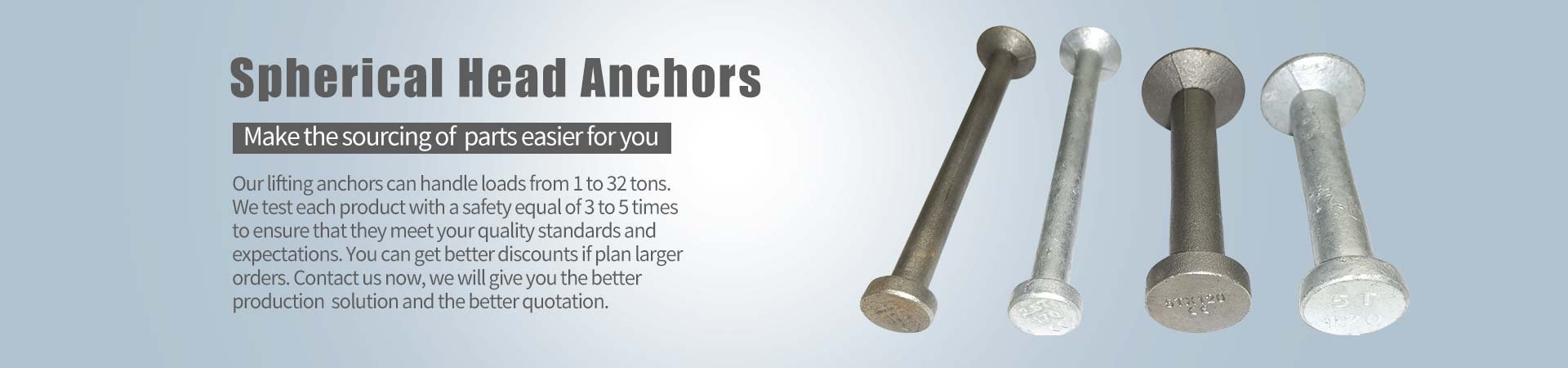

spherical head anchors

Definition

HULK Metal's spherical head anchors are made from round steel, such as Q345, 20Mn2, CM490, and stainless steel. The load capacities of these anchors are from 1.3 to 32 tons, with a safety factor of at least 3 times which makes them suitable for working with higher loads. The length of the spherical anchors varies depending on their specific application. Therefore, it is important to choose a suitable length when lifting different units. Common surface treatments for spherical head anchors are hot-dip galvanized, electro-galvanized, and raw color. The spherical head anchor passed CE-certified. They are also manufactured in ISO 9001-certified workshops which can ensure higher quality.

Instructions

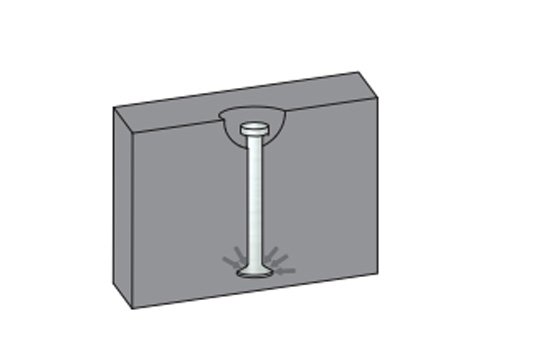

Even in thin-walled structures, the load can be securely transmitted into the concrete.

The round symmetrical shape of the anchor foot eliminates the need for specific positioning during installation.

The Spherical Head Anchor offers advantages over the re-bar in terms of concentrated load distribution for typical wall thicknesses,

as opposed to the gradual and supposedly gentle load transfer.

Extensive tests conducted at the Technical University in Darmstadt

have demonstrated that the anchor foot initiates a cone-shaped cracking pattern.

Using longer anchors with greater embedments activates a larger section of concrete.

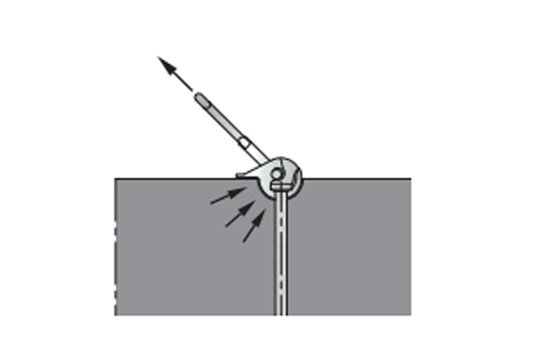

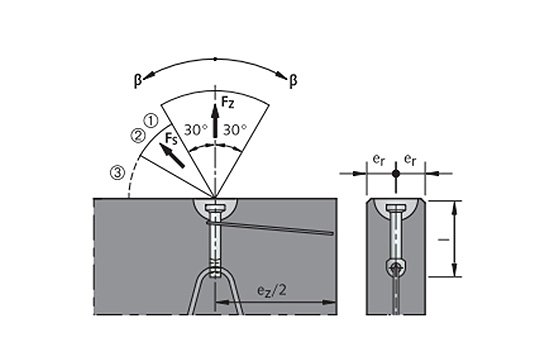

Due to the presence of corresponding Lifting Clutch and Recess Former for each lifting group, it is impossible to incorrectly couple parts from different Load groups. Another benefit is that during the diagonal pull, the Lifting Link rests against the concrete, enabling the direct transfer of horizontal load into the concrete. Additional reinforcement is required for slope tension in thin-walled elements.

However, if the transverse tension is at a 90° angle to the floor plane,

meaning that the wall elements are vertically sloping, no extra reinforcement is needed (Details on page 10).

Other wall units do not require additional reinforcement.

Installation Process

1. Utilize the Recess Former to attach the Spherical Head Anchors to the specified

location on the concrete block formwork prior to pouring.

2. Remove the Recess Former once the concrete block has fully dried.

3. Upon removal, the Recess Former will create a gap that accurately aligns with the

Lifting Clutch.

The length of the Spherical Head Anchor is designed for optimum loading depending on the

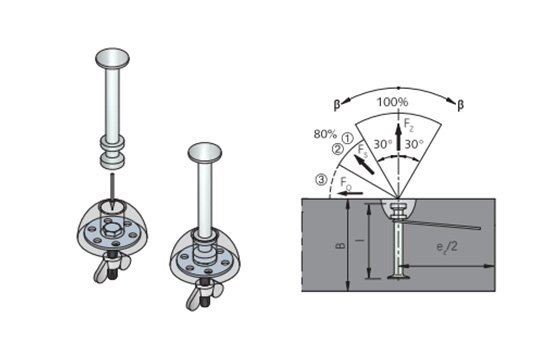

Figure 1: the expected question type.

Figure 2: the situation will not occur.

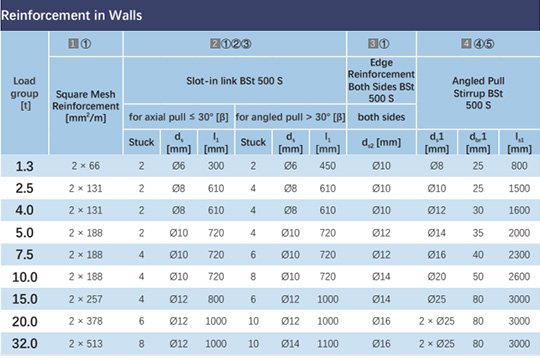

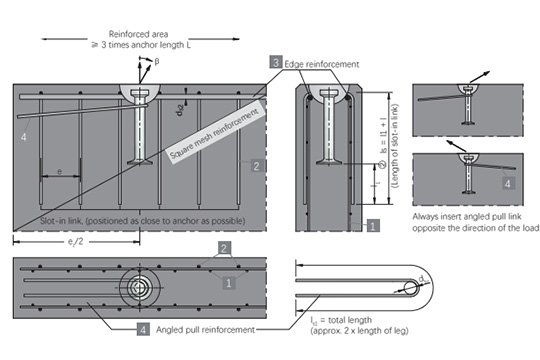

with very thin panels (2 × er ≤ 70) the square mesh can be taken together in one layer (for example 2 × 66 mm2/m required, lay 1 × 132 mm2/m in the middle).

The slot in links in this case can be placed on the skew, but the edge reinforcement must be placed on both sides of the anchor.

2.The length of the link (ls) = length of the anchor (l) + the dimension in the chart above (l1).

3. The slot-in links should be spaced out on each side of the anchor in zone 2.5 × the anchor length, but the first side must be as close as possible to the recess former.

4. Angled pull reinforcement is only needed if β > 30°. Angled pull reinforcement, may not be required if the edge distance is greater (see the following charts).

5. If the dimension of the precast element restricts the length of angled pull reinforcement, then the bar may be bent vertically up to the last 40 % of the length.

Lifting Eye Anchor

Definition

Lifting Eye Anchors are Lifting Anchors with a hole in one end. Lifting Eye Anchors should be used with a reinforcement tail together when the spherical head anchor cannot bear the load. Such as roof beams or double "T"-beams. Lifting eye anchors are also suitable for lightweight concrete as the load is transferred over the large area of the reinforcement tail.

Instructions

1. Angled pull at β > 30° without reinforcement for the angled pull is only allowed at Concrete strength 15 N/mm2 and wall thickness 3 times minimum thickness 2×er. Concrete strength 25 N/mm2 and wall thickness 2.5 times minimum thickness 2 x er.

2. At a concrete strength > 23N/mm2. FZ = FS.

3. Angled pull with β > 60° caused by the spread of cables/chains is not permitted!

Warning:

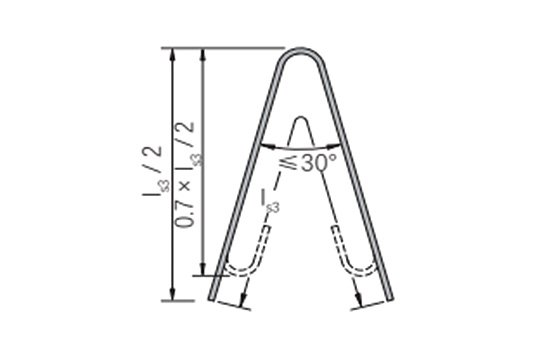

All the load is transferred to the ribs of the rebar tail.

The tail must be installed tight to the base of the hole in the anchor.

The tail must be bent with an internal angle of 30 as shown.

The tail may be shortened if required by forming end hooks as shown.

The reinforcement tail is essential. The anchor must not be used without the tail.

Spherical Double Headed Lifting Anchor

Definition

The load capacity of double-head lifting anchors is the same as spherical head anchors,

and the anchor suits the same lifting clutch. But the recess formers of double-head lifting anchors are difficult.

Currently, commonly used recess formers are rubidium magnets.

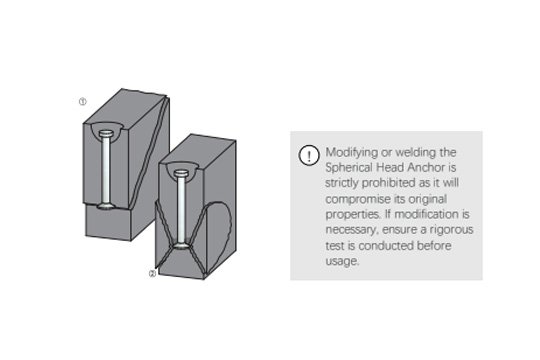

The difference between a Double Head Anchor and a Spherical Head Anchor is a collar below the anchor head.

This design makes it push into the recess more quickly and can make a seal.

Instructions

Assembly is faster, and the former remains on the mold when demolding. This is especially beneficial

for negative castings like balconies or staircases.

1. Angled pull at β > 30° without reinforcement for the angled pull is only allowed

at:

Concrete strength 15 N/mm² and wall thickness 3 times minimum thickness ez/2

Concrete strength 25 N/mm² and wall thickness 2.5 times minimum thickness ez/2

Concrete strength 35 N/mm² and wall thickness 2 times minimum thickness ez/2

2.At a concrete strength > 23N/mm² FZ = FS.

3. Angled pull with β > 60° caused by the spread of cables/chains is not permitted

Utility Anchor

Definition

Utility Anchor is a commonly used lifting anchor in precast concrete components. It is efficient, safe, and widely applicable. Utility Anchor can ensure smooth lifting operations by being used in combination with corresponding lifting rigging (such as lifting rings, lifting clamps, etc.). Its installation process is simple and efficient. It only needs to be buried in the concrete and connected during lifting through the matching anchor cable system. In order to meet different construction needs, Utility Anchor provides a variety of specifications and sizes to cope with components of different weights and volumes.

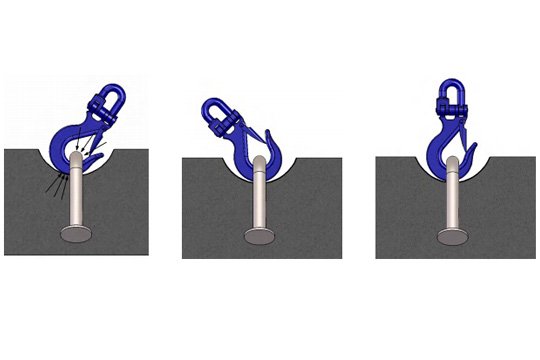

Instructions

The hook must not contact the concrete beneath the anchor loop. This will result in a prying

action and could cause premature failure.

The hook must not contact the concrete element.

The hook must not contact the concrete element

Warning

The placement of the Utility Anchor is dependent on the structural shape of the precast element. Utility anchors are not designed for thin-edge installation. Always maintain minimum edge distances.

Lifting Anchor Factory

Professional Design and Customization

At HULK Metal, we know that every project has its own unique needs, so we provide a wide selection of standard products and custom designs based on the specific needs of customers. Whether it is the product size, material selection, or surface treatment requirements, our engineering team has sufficient technical capabilities and rich experience to tailor the lifting anchor products that best meet the needs of customers' projects.

We welcome OEM cooperation and have a complete set of production processes and equipment to quickly respond to customers' customized needs. Whether it is producing small batches of prototype samples or large-scale mass production, we can ensure efficient delivery.

Exclusive Solutions

HULK Metal is committed to providing exclusive, thoughtful, and unique solutions for each customer. We deeply understand the complexity and diversity of various engineering projects, so our team of engineers will work closely with customers at every stage of the project launch to deeply understand their needs and project characteristics. Through this close cooperation, we are able to provide customers with the most suitable lifting anchor products to help them successfully complete various construction tasks.

Strict Quality Control

Quality is one of the core competitiveness of HULK Metal. We implement strict quality control in every production link from the purchase of raw materials to the delivery of finished products to ensure that each lifting anchor meets the highest standards. We have advanced testing equipment and a complete quality management system, which can perform a variety of physical performance tests, including strength tests, corrosion resistance tests, and load capacity tests.

Thoughtful packaging service

To ensure that the products are not damaged during transportation, we provide professional packaging services. We design appropriate packaging methods according to the characteristics of different products to ensure that the lifting anchor remains intact during long-distance transportation. Our packaging team will carefully check the packaging of each product to ensure that it can withstand different transportation conditions. Whether it is land, sea, or air transportation, our products can reach our customers in the best condition.

Special discounts and sales area protection

To support our dealer partners, HULK Metal offers a competitive special discount policy. We always value long-term cooperative relationships with dealers, so we provide dealers with customized discount plans to help them maintain price competitiveness in the market and maximize profits.

The rational selection and correct use of various types of Lifting Anchors are the basis for ensuring the safety and efficiency of prefabricated component lifting operations. From spherical head anchors to spherical double-headed lifting anchors, each type of lifting anchor provides a unique solution for specific construction needs and component design. In actual operation, construction workers must strictly abide by the installation and use specifications of each lifting anchor to avoid unnecessary damage and safety hazards. With the development of prefabrication technology, the lifting anchor is also constantly innovating, and its application in more complex structures in the future will further promote the progress of the construction industry.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.Lifting Clutch VS Lifting Ring Clutch:Definition, Working Principle, Application Scenarios, and Selection Guide

- 2.Concrete Screws:Which Type Should You Use?

- 3.Detailed explanation of the types, applications and design principles of spread anchors

- 4.Lifting Anchors: An Essential Component in Construction and Heavy Lifting

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.