Precast Concrete Magnet Full Introduction

Precast Concrete Magnet

Definition

Precast Concrete Magnets represent an innovative advancement in modern construction, offering a highly efficient, reliable, and cost-effective solution for securing concrete formwork during the precast process. These magnets are specifically engineered to hold various types of formwork in place, ensuring precision and stability throughout the concrete casting process. This relatively new technology has quickly gained recognition in the construction industry due to its ability to streamline operations, reduce labor costs, and improve overall project timelines. Unlike traditional methods, which may involve bolts, clamps, or welding, Precast Concrete Magnets eliminate the need for complex and time-consuming setups, resulting in a cleaner and safer working environment.

Classification

According to specific usage situations, the precast concrete magnet can be classified into Shuttering Magnets, Magnetic Recess Former, and Concrete Insert Magnets.

Shuttering Magnets

Structure and Elements

Shuttering Magnets, also known as magnetic boxes, are indispensable fixing tools in the precast concrete industry. Its core components include neodymium iron boron (NdFeB) magnets, steel housings, magnet plates, and control knobs.

Magnetic On/Off Switches:

Our magnetic switches are made of 201 or 304 stainless steel and are precision machined to ensure smooth operation. We adopt a random inspection method, and each switch undergoes more than 100,000 fatigue simulations to prevent any deformation or failure. The user-friendly design allows for quick activation and deactivation of the magnetic field, simplifying the formwork installation process.

Fixing Screws (Compliant with National Standards):

We offer sturdy fixing screws, manufactured according to the GB/T 15389-94 standard. These screws are designed to fix different types of side rail devices with excellent adaptability. For loads under 1000 kg, we use M12 screws, while for loads over 1000 kg, we use M16 screws to ensure strength and reliability.

High-Performance Neodymium Magnets:

Unlike many competitors who reduce costs by adding more than 12% of lanthanum and cerium to their neodymium magnets – which compromises their coercivity (Hcb) and intrinsic coercivity (Hjc) – our magnets maintain superior long-term performance. While such low-cost magnets lose 10-15% of their magnetic field after 6-10 months, our magnets retain their strength due to stringent quality control. Neodymium magnets account for more than 50% of the total magnet cost, and since we have been producing our own magnets for a decade, we can ensure quality and affordability. Our magnets are available in N and M grades, have a maximum operating temperature of 80°C, feature a premium zinc coating for corrosion resistance, and have a magnetic force range of 450 kg to 3500 kg.

Protective Iron Casing:

The neodymium magnets are enclosed in a premium iron casing to prevent potential damage during switching operations. The casing also provides partial protection against corrosion and oxidation, extending the life of the magnets. The housing design is easy to clean with a pneumatic air gun or electric brush.

Durable Plastic Housing:

Our Shuttering Magnets feature a high-quality ABS plastic housing that offers excellent heat and wear resistance. This ensures the magnets can withstand the harsh construction environment.

High-quality Springs:

The integrated springs are made of alloy steel and are oil-quenched for excellent fatigue resistance. The springs are three-stage high-pressure treated to eliminate internal stress and shot-peened to increase stress concentration strength. They have a service life of over one million cycles, providing long-term reliability.

Housing and Surface Treatment:

The housing of Shuttering Magnets is made of stainless steel or Q235 steel, precision-cut by laser. The surface of Q235 steel is blackened, and we also offer environmentally friendly spray paint and baked finishes in custom colors.

Stainless Steel Studs:

Our stainless steel studs ensure secure fastening and provide more than three years of rust resistance, helping to increase the durability and service life of Shuttering Magnets.

HULK Metal is a professional manufacturer specializing in shuttering magnet manufacturing and is dedicated to providing efficient and reliable magnetic fixing solutions for the global construction and prefabrication industries. We provide customers with a variety of specifications and customized services to ensure that the special needs of various projects are met and provide a guarantee for the smooth implementation of the project with high-cost performance.

Magnetic Recess Former

Introduce

Steel Recess Former Magnet is ideally designed for fixing lifting anchors on the side mold, instead of traditional rubber recess former screwing. The semi-sphere shape and the center srew hole make it easy to take off from the concrete panel when demoulding.We are filled with 1.3T, 2.5T, 5.0T, 7.5T, or 10T types for different-sized lifting anchors. An additional rubber seal is also necessary to hold the anchor firmly in the recess of the former magnet hole. Even though different countries use different thread formats, we can provide them all, so don't worry, we can meet all your needs.

Composition

The steel magnetic former is made of metal and NdFeB magnet

Use

The steel magnetic former is designed to help the lifting anchor stay in place in the precast concrete slab, and it is attached magnetically to the steel formwork, allowing it to be quickly positioned or removed. When the shear cone caused by the lifting anchor results in insufficient tensile strength of the concrete, the foot anchor is replaced with the lifting eye anchor.

The lifting anchor and lifting eye anchor are secured in the groove by a special open rubber ring that wraps around the anchor rod, just below the anchor head, and then wedges into the mouth of the in-place groove former. Once the casting is complete and the concrete has fully cured, the magnetic steel groove can be easily removed automatically or manually using a magnetic force. Simply remove the ring from under the anchor head and the precast unit is ready for lifting. Clean the steel groove thoroughly immediately after removal and apply release oil before each use.

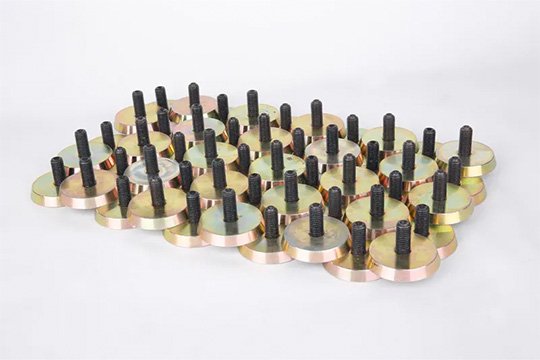

Concrete Insert Magnets

Introduce

Precast Insert magnet, also known as Embedded Fixing Magnet, inserted socket fixing magnet, embedded socket fixing magnet, magnetic pipe fixing magnet, and precast concrete fixing magnet.

Precast Insert Magnets are mainly used in construction sites, railway infrastructure, and some other projects. This is a new kind of building material, which can ensure the stability of the building. These magnetic fixing plates can be used to fix the socket system or accessories to steel formworks. NdFeB magnetic nailing plate is widely used for precast anchors, neodymium magnet socket holders, magnetic nailing, etc. At the same time, tube magnet is a perfect choice if you want to position pipes, and tubes in precast parts.

Composition

The precast insert magnet is made of metal and the NdFeB magnet

Use

In terms of use, the Insert Magnets are designed to be compatible with a range of precast concrete production units. During use, one side of the magnetic component is securely fixed to the steel formwork or casting platform. The other side secures the embedded insert, ensuring it remains in the precise desired position within the precast concrete unit. The strong magnetic force accurately and stably positions the embedded component, reducing the need for manual adjustments and minimizing misalignment. This can make the production process more efficient, increase accuracy, and reduce errors in the final concrete product. Insert Magnets are very useful for securing embedded components such as lifting anchors or connection points, making them an essential tool in modern precast concrete manufacturing.

Advantages of the precast concrete magnet

Labor and material costs can be greatly reduced, and it also improves the efficiency of the installation.

It can be accurately positioned very easily.

The screw, bolt, and welding process can be avoided during positioning, the stainless steel plate is free of damage.

It is reusable so that it can have a long service life with a shorter payback.

It significantly improves the operating environment while ensuring safety.

Why buy precast concrete magnets from us?

Wide range of specifications and strong bonding:

We offer magnets in a variety of specifications from 450Kg to 3100Kg, which can provide a one-stop solution for your project to meet different needs.

More than ten years of experience in the production of NdFeB magnets:

We have more than 10 years of experience in the production of NdFeB magnets. All NdFeB magnets are produced by our own factory to ensure strict quality control. We also provide a 3-year quality warranty to ensure long-term performance of the product.

Professional assembly team:

Our employees have been systematically trained and have more than 3 years of experience in magnetic assembly. We optimize the assembly process to reduce loss and damage while improving assembly efficiency.

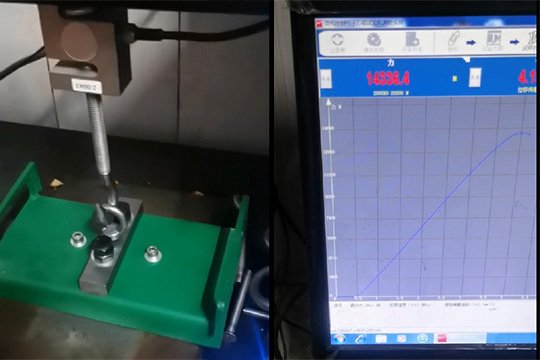

Strict quality control:

Standardized production processes and a comprehensive quality inspection system ensure that the products meet high standards in all aspects from materials to functions, tensile strength, etc.

Competitive prices and high-quality services:

Our products are more competitive in price and stable in quality compared to other brands on the market. The quality complaint rate in 2022 is 0‰, and we promise to respond quickly to customer needs within 12 hours.

As a professional manufacturer focusing on magnetic fixing solutions, HULK Metal is well aware of customers' needs for accuracy and efficiency during construction. Our products cover a variety of specifications to meet various engineering needs. More than ten years of experience in the production of NdFeB magnets has given us unique advantages in material selection and quality control, ensuring that each product can withstand the harsh construction environment.

We are committed to providing customers with high-quality services and technical support to ensure that every customer can get the most satisfactory experience when using our products. At the same time, our after-sales service team always maintains an agile response to ensure that any problems you encounter can be solved in time. Choosing our Precast Concrete Magnets means choosing a future of high quality, high efficiency, and high-cost performance, which will help your project go smoothly and succeed.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.Lifting Clutch VS Lifting Ring Clutch:Definition, Working Principle, Application Scenarios, and Selection Guide

- 2.Concrete Screws:Which Type Should You Use?

- 3.Detailed explanation of the types, applications and design principles of spread anchors

- 4.Lifting Anchors: An Essential Component in Construction and Heavy Lifting

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.