Comprehensive Overview of Lifting Ring Clutch: Design, Functionality, and Safety Considerations

Definition

A lifting ring clutch is a manually operated coupling device widely used in combination with Spread Anchors for lifting and hoisting scenarios. Its main function is to fasten it to the anchor hole in the precast concrete component through the locking pin embedded in the ring-shaped Clutch Head. When used in conjunction with the plate anchor, the Ring Clutch can ensure the safe lifting, rotation or tilting of precast concrete components.

The design of the lifting ring clutch not only supports axial (vertical) loads but also can cope with multi-angle operations, such as horizontal or inclined handling operations, which is particularly important in the transportation of large or complex precast components. Its flexible operating characteristics make it an important tool widely used in construction, bridges, tunnels, and other infrastructure projects.

Composition and working principle

A standard Ring Clutch system usually consists of the following key parts:

In the lifting industry, the Ring Clutch system is a very efficient and safe connection device, which is widely used in the lifting of precast concrete parts. A standard Ring Clutch system usually consists of the following key parts to ensure its safety and flexibility in high-load operations:

Shackle:

The shackle is the core connection component in the Lifting Ring Clutch system. It is usually made of high-strength alloy steel and has a very high load-bearing capacity. Its main function is to achieve a safe connection between the lifting equipment (such as a crane or a lifting chain) and the load. The design of the shackle takes into account the uniform distribution of the load and can withstand tension from different directions, thereby ensuring stability and safety during the lifting process.

Locking Bolt:

The locking bolt is a key component to ensure the safe operation of the Ring Clutch system. Its main function is to fix the components through the locking mechanism after the connection is completed to prevent loosening or accidental detachment. The design of the locking bolt is usually easy to operate and has an automatic locking function, which not only improves work efficiency but also effectively reduces safety risks caused by manual operation errors.

Clutch Head:

The clamp head is the part of the Ring Clutch system that directly contacts the embedded parts. Its special geometric design can fit tightly with the anchor point or be inserted in the concrete to ensure the safe transfer of the load. The clamp's manufacturing material is usually high-strength steel, which has undergone special heat treatment. It has wear and corrosion resistance characteristics and can be used stably for a long time. The design of the clamp also takes into account the need for rapid disassembly and assembly, making it efficient in operation.

The various components of the Ring Clutch system complement each other. Through precise structural design and high-quality manufacturing processes, its reliability and safety in heavy lifting operations are guaranteed.

Performance characteristics of Ring Clutch

Standardized design and compliance:

The ring lock produced by HULK Metal implements the EN 1677-1 standard. This is one of the most stringent load-lifting equipment standards in Europe, covering safety, load capacity, durability, and other requirements. Compliance with this standard means that Ring Clutch can provide reliable performance guarantees during operation.

Heat treatment process:

The quenching and tempering processes ensure that Ring Clutch has sufficient strength and toughness under different working conditions. Quenching increases the hardness of the material, and tempering balances the hardness and toughness, so that it can not only carry heavy loads but also is not easy to break brittlely under impact.

Surface treatment:

Surface treatment is essential for the protection of metal parts. HULK Metal offers powder coating or galvanized surface treatment, each for different environmental use requirements. Powder coating has good wear resistance and corrosion resistance, while galvanizing excels in preventing oxidation and rust, especially suitable for long-term use in harsh environments.

Safety Use Specifications and Maintenance

As a heavy load equipment, Ring Clutch, operational safety is the top priority. In order to ensure long-term safe use, regular inspection and maintenance are required.

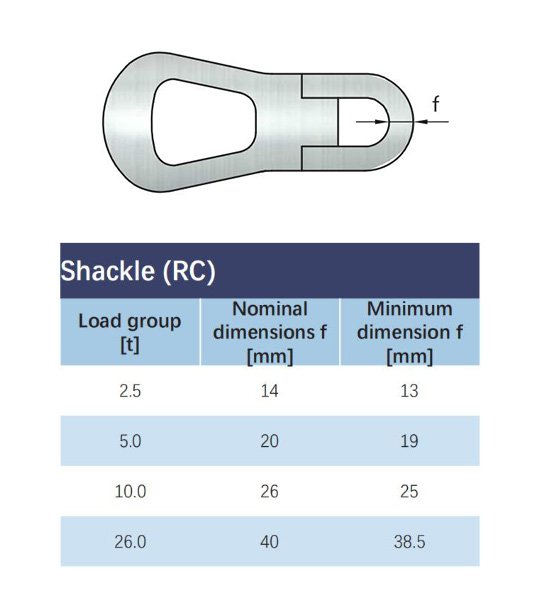

Shackle Inspection

As the connecting part between the Lifting Ring Clutch and lifting equipment, the shackle bears extremely high stress. Therefore, whether the shackle is intact is directly related to the safety of lifting. Before the operation, the shackle must be carefully inspected. If any visible damage or excessive wear is found, it should be immediately decommissioned and replaced. According to the technical specifications of the load equipment, the allowable wear range is clearly stipulated, and equipment that exceeds the allowable tolerance will no longer be safe to use.

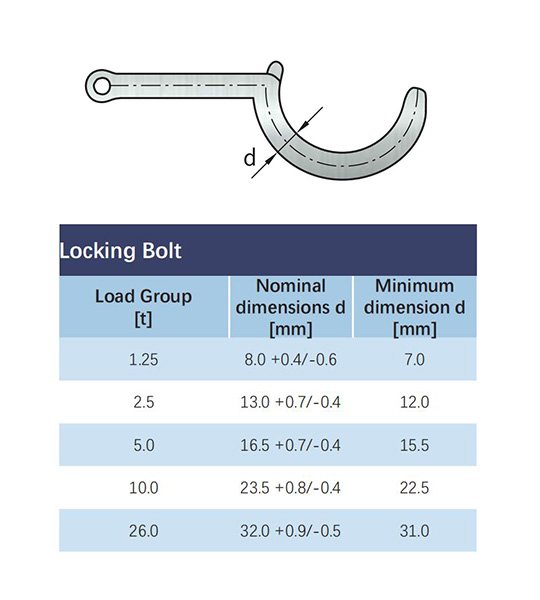

Locking Bolt Inspection

The locking Bolt is one of the core components of the Ring Clutch, and its safety directly affects the entire lifting operation. During the inspection, attention should be paid to the wear of the Locking Bolt. If the Locking Bolt is found to be bent or has obvious signs of wear, it must be stopped immediately and replaced in accordance with the technical specifications. Any locking pin that exceeds the allowable wear tolerance may fail during operation, causing serious safety accidents.

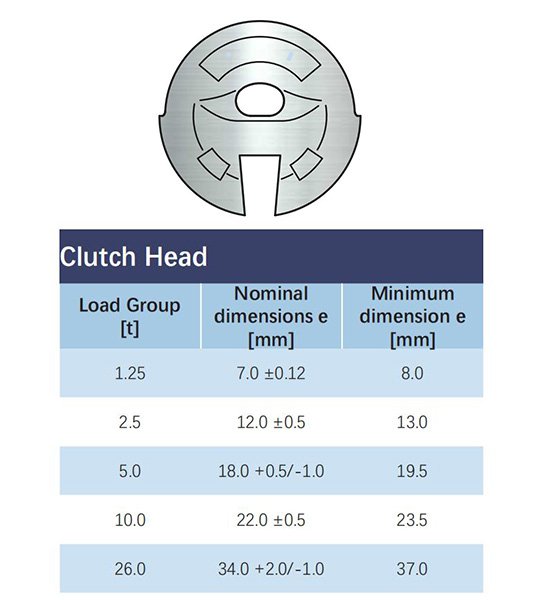

Clutch Head Inspection

As a key load-bearing component of Ring Clutch, the Clutch Head must ensure its structural integrity. Special attention should be paid to whether there is excessive opening at the mouth. If the mouth size is found to exceed the allowable range or the lock head is deformed, the equipment must be stopped immediately and cannot be repaired. Because it is directly related to whether the locking pin can be locked correctly and the stability under load, any damage will affect the safety of the operation.

Packing and Inspection Process

During transportation and storage, reasonable packaging design can effectively protect the Ring Clutch from damage or rust. For small products, HULK Metal uses bags and plywood boxes for protection, while for large products, plywood boxes are used directly for packaging. This packaging method not only effectively prevents damage caused by external impact, but also resists the risk of corrosion in humid environments.

Application and Misuse of Ring Clutch

Application of the Ring Clutch

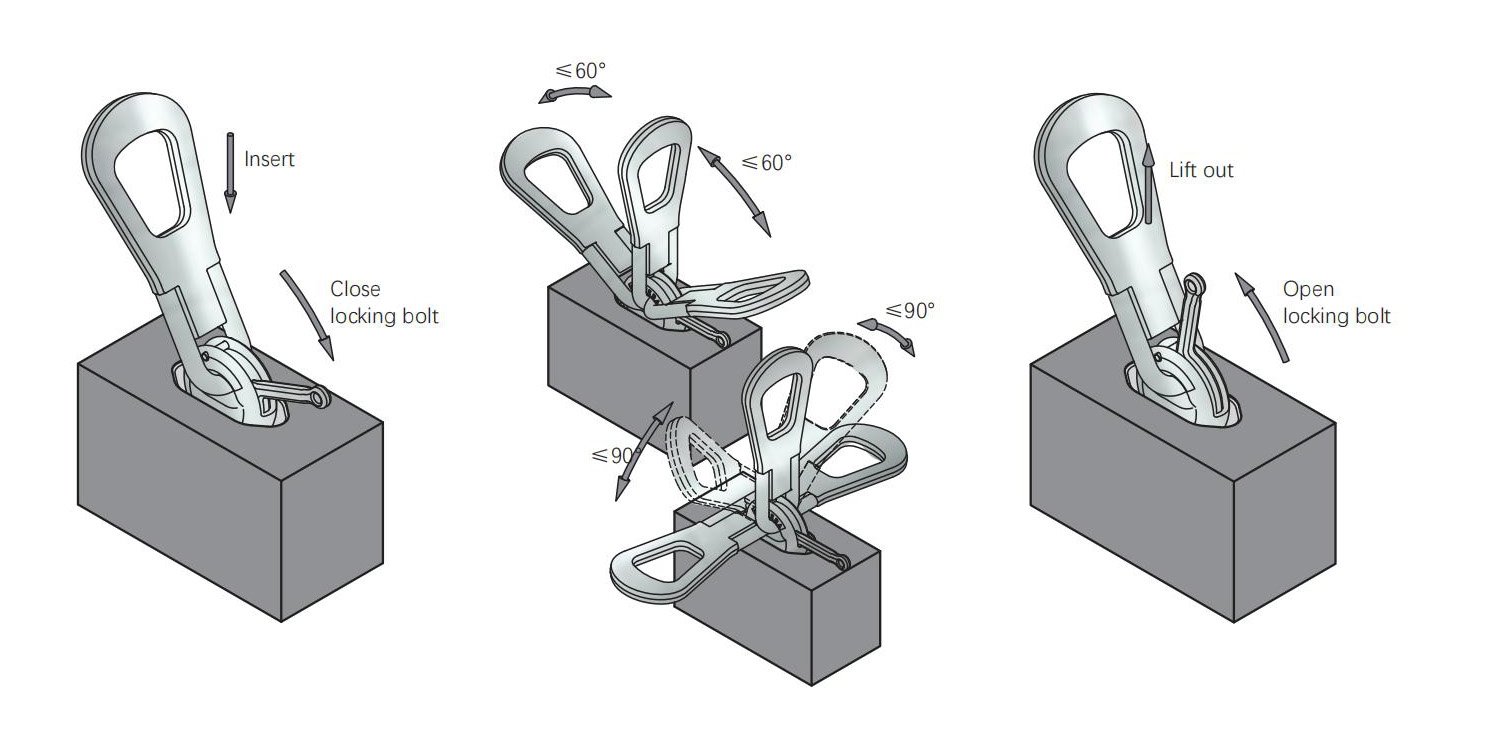

Engaging:

Insert the ring clutch into the recess in the concrete and securely fasten the locking bolt or slide manually until it reaches the maximum position. Proceed with the lifting operation.

Lifting:

The ring clutch can be subjected to loads in any direction (do not exceed the load limits of the anchors!). Angled pull of up to 60°due to the use of a spreader is permissible.

Releasing:

Manual ring clutch: push back the bolt by hand. Now the ring clutch is released.

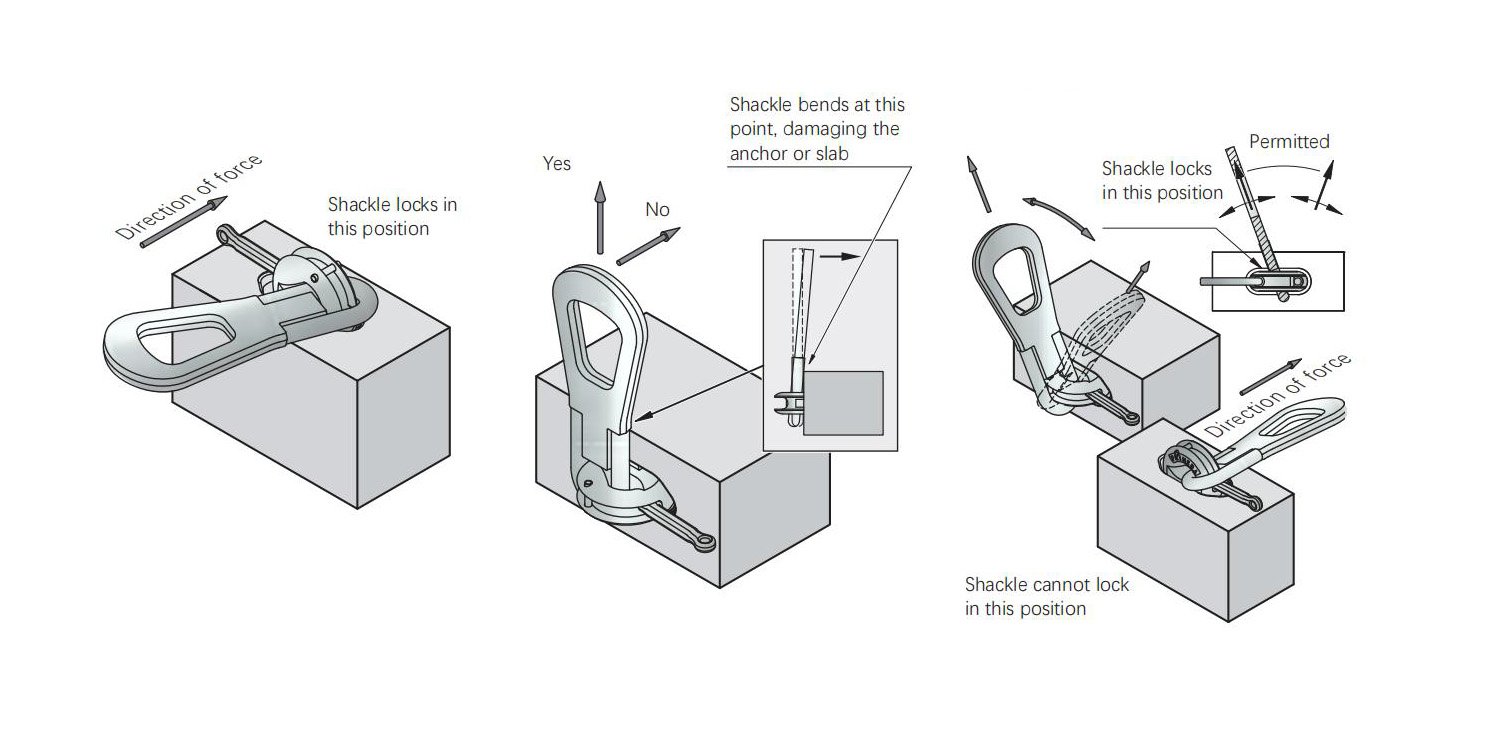

Misuse of the Ring Clutch

If the shackle is beneath the clutch head when subjected to the load, it may lock in the position illustrated. The round shackle will become bent when the load is raised.

If the shackle is pulled towards the top surface of the slab when subjected to the load, it may become bent on the edge of the slab.

In the upper position, the shackle may lock within the clutch housing. A narrow lifting cable angle will cause the shackle to become bent. The problem can be overcome by turning the shackle through approx 45° .

Experimental Testing and Quality Control

When quality testing lifting ring clutches, the following three inspection steps are crucial to ensure product reliability and safety.

100% Flux Crack Testing

Flux crack testing is a non-destructive testing (NDT) method widely used to find surface and near-surface defects in ferromagnetic materials. For lifting ring clutches, the use of magnetic particles and magnetic fields can reveal potential cracks or defects. By applying a strong magnetic field, any tiny crack will cause magnetic flux leakage, attracting magnetic particles and showing the exact location of the crack. This step is particularly suitable for identifying tiny cracks that may affect the performance of the lifting ring clutch, thereby avoiding its failure in heavy-duty environments.

Tensile Testing

Tensile testing is used to determine important mechanical properties such as tensile strength, yield strength and ductility of lifting ring clutches. By applying increasing tensile force to the specimen until it breaks, the test equipment records the mechanical properties of the specimen during the stretching process. This test ensures that the lifting ring clutch can maintain stable performance when loaded, especially when used in extreme conditions. The results of the tensile test are an important basis for evaluating product quality and material selection. We will test a sample of lifting ring clutches to ensure that the order qualification rate reaches 100%.

Dimensional inspection

Dimensional inspection uses precision measuring tools (such as calipers, three-coordinate measuring machines, etc.) to confirm whether the geometric dimensions of the lifting ring clutch meet the design requirements. Deviations may affect the assembly and the load-bearing capacity of the product. This step is crucial to ensure that the tolerances of each lifting ring clutch during the manufacturing process meet the specifications to avoid installation difficulties or safety hazards caused by dimensional deviations.

Through these rigorous testing steps, the quality and performance of the lifting ring clutch can be guaranteed to meet the safety and reliability requirements of industrial applications.

Why choose HULK Metal?

On-time delivery:

HULK Metal's supply chain is optimized to effectively reduce the intermediate links, ensure that the products can be delivered to customers on time, and avoid construction projects being stalled due to equipment delays.

Comprehensive quality control:

Every Ring Clutch product shipped out of the factory is subject to strict quality inspection. From the procurement of raw materials to every link of the production process, we have formulated strict control standards to ensure that the products meet international industry standards and guarantee their reliability in various applications.

Completely transparent production process:

HULK Metal is committed to providing every customer with a fully transparent order tracking service. From order confirmation to production completion, we will provide real-time progress updates, including detailed quality inspection reports and shipping photos. Customers can keep track of the progress of their orders at any time to ensure that the product quality meets expectations.

Professional customer service:

We provide one-to-one exclusive customer service for each customer. Whether the customer is consulting product information or making special customization requirements, HULK Metal's team will respond within 8 hours to ensure that the customer's problem can be solved in a timely manner.

As indispensable equipment for the lifting of heavy prefabricated components, the design and operation safety of the Lifting Ring Clutch is of paramount importance. Through reasonable structural design, high-strength material selection, and strict quality control, the Lifting Ring Clutch can not only meet the needs of different loads but also ensure safety and stability under various working conditions.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.Spherical Head Lifting Anchor: In-depth discussion of materials, production processes, quality inspection procedures and supplier selection guide

- 2.A comprehensive introduction to Lifting Anchor

- 3.How to Choose High-Quality Shuttering Magnetic Products and Suppliers Guide

- 4.Applications and advantages of swivel hoist rings: HULK Metal provides you with safer and more flexible lifting solutions

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.