Lifting Clutch: Definition, Operation Guide and Comprehensive Analysis of Supplier Selection

1. Definition

A lifting Clutch is a strong and durable lifting device widely used for handling and installing precast concrete components. The standard lifting capacity ranges from 1.3 tons to 32 tons, meeting the needs of various construction and engineering projects. This type of lifting clutch complies with the EU Machinery Directive 2006/42/EC and VDI/BV-BS 6205 standards, ensuring its high level of performance in terms of safety, durability, and efficiency. These standards provide comprehensive quality assurance for the design, manufacture, and use of lifting clutch, enabling it to withstand complex and heavy-loaded working environments.

Lifting clutch has various names

Lifting clutches are called different things in different regions. Some regions call it doge bone lifting anchor, lifting eye clutch, Pin Anchor Ring Clutch.

Dog bone lifting clutch: This name comes from its use with the dog bone lifting anchor, so in actual construction, many people are accustomed to calling it Dog Bone Lifting Clutch

Lifting eye clutch: This name refers to a clutch with a lifting ring, which is used for lifting operations in specific application scenarios.

Pin anchor ring clutch: This name emphasizes the ball head anchoring design of the clutch, which is often used in the Pin Anchor Ring system.

About HULK Metal's Lifting Clutch

Available in capacities:

1.3T, 2.5T, 5T, 10T and 32T. Each specification of equipment is strictly tested before leaving the factory to ensure that it can operate safely and efficiently within the specified load range.

Safe, quick and efficient:

Lifting Clutch not only provides extremely high load-bearing capacity, but also has the characteristics of quick and efficient operation. In actual operation, the clutch's design enables it to easily cooperate with the anchor, avoiding complicated installation processes and greatly improving work efficiency. At the same time, the T-slot design ensures the stability of load transfer during the connection process, further improving the safety of lifting operations.

Marked with WLL, CE Mark and an individual serial number:

HULK Metal's Lifting Clutch complies with the EU's Machinery Directive standards, which means that it meets the highest safety standards in product design, manufacturing and use. In addition, to meet the different needs of customers, we provide third-party test reports to assist customers in obtaining international certification and ensure the recognition of products in the global market.

Safe Working Load of the Lifting Clutch is based on a factor of 5 for safety:

Safe Working Load (WLL) is designed based on a safety factor of 5. This means that even under extreme load conditions, the equipment still has sufficient safety margin to ensure that there will be no accidents or equipment damage caused by overloading during lifting operations. In order to further enhance the safety and traceability of the product, all HULK Metal Lifting Clutches are marked with working load limits (WLL), CE marks and unique serial numbers.

Steps to operate the Lifting Clutch

In actual operation, the Lifting Clutch is very flexible and easy to use. Its T-slot design enables it to easily engage with the head of the dog bone lifting anchor, ensuring stable load transfer and operational safety.

Coupling

The coupling operation is the most basic and critical step in using the Lifting Clutch. It is necessary to ensure the correct matching of the anchor and the lifting device. The following are the detailed steps:

Check the load capacity:

Before operating, first check whether the load capacity of the anchor meets the lifting requirements. The Lifting Clutch has a clear load limit, so under no circumstances should the load limit of the anchor be exceeded, otherwise it may cause equipment damage or cause safety hazards.

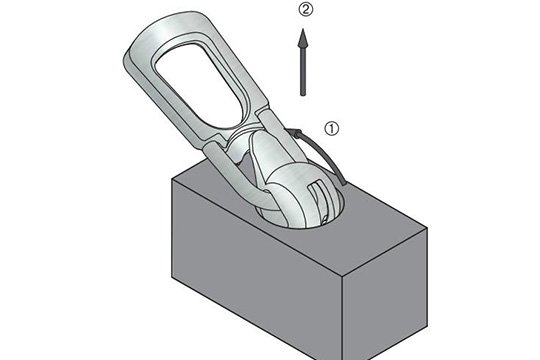

Engagement device:

When connecting the Lifting Clutch to the anchor, first push the opening of the spherical head down onto the ball head of the anchor. At this time, ensure that the anchor is fully entered into the opening of the spherical head and is in close contact with the body of the clutch.

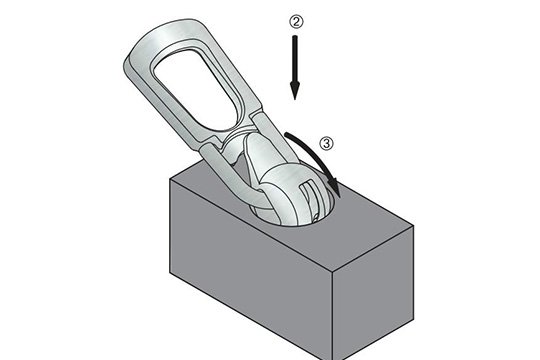

Fixing:

Rotate the tongue at the bottom of the ball head downward so that it tightly surrounds the anchor. This process ensures a secure connection between the Lifting Clutch and the anchor, providing the necessary stability when the load is lifted. After securing, the clutch is ready for lifting operations.

During this process, it is crucial to keep the connection clean and free of obstructions. Any foreign matter or dirt may cause a poor connection, which in turn affects the safety of the equipment.

Lifting

Lifting operation is one of the core functions of using the Lifting Clutch, which can cope with a variety of different loads and operating environments. The following are the main steps and precautions for lifting operations:

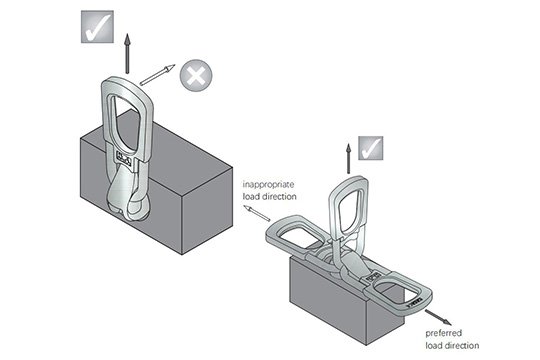

Axial load and tilting operation:

The Lifting Clutch is designed to handle axial loads and allow limited tilting operations during lifting. This design provides workers with flexibility and can better adapt to complex construction environments.

Rotation operation:

During the tilting operation, the Lifting Clutch can rotate on the lifting chain, which allows workers to be more flexible when handling precast panels. The rotation operation needs to be carried out under the premise of ensuring that the tongue is closed to avoid load instability.

Load release control:

During the lifting process, the balancing function of the tongue ensures that the spherical head remains in the correct position, even when the load is released. The design of the tongue allows operators to better control the equipment and reduce unexpected operating errors.

Lubrication:

During the rotation operation, if the rotation is difficult due to friction, grease can be used in moderation to improve the smoothness of the operation. However, lubrication should be used with caution to prevent excessive slippage or loss of control.

Release

After the lifting operation is completed and the load is safely placed, the Lifting Clutch must be released correctly to ensure the safety of the equipment and the smoothness of the next use. The steps of the release operation are as follows:

Release the load:

When the load has been unloaded, the tongue can be turned to the release position by rotating the spherical head. This operation needs to be performed under the condition that there is no load, otherwise it may cause damage to the equipment or cause safety hazards.

Remove the equipment:

After releasing the Lifting Clutch, it needs to be completely removed from the anchor to prevent it from swaying in the air or uncontrolled contact with other equipment or workpieces.

Through standardized operating procedures, every use of the Lifting Clutch can be ensured to be safe and efficient, and its service life can be extended.

How to choose the right Lifting Clutch supplier

When choosing a Lifting Clutch supplier, you need to consider several key factors to ensure that the products and services provided by the supplier can meet the needs of the project. The following are the main considerations when choosing a supplier:

Quality control

Lifting Clutch is a key equipment for handling heavy loads and complex operations, so its quality is directly related to the safety and efficiency of the construction process. When choosing a supplier, first make sure that they have a sound quality control system, such as companies that have passed international quality management system certification such as ISO 9001. These certifications ensure that suppliers can provide high-quality products that meet industry standards and strictly follow various quality control processes during the production process.

HULK Metal has passed ISO9001 certification, ISO14001, ISO45001 certification.

Technical support

Technical support is one of the important indicators to measure the supplier's capabilities. A good Lifting Clutch supplier not only provides products, but also should have a complete technical support service, including product installation guidance, usage training, troubleshooting, etc. In actual projects, Lifting Clutch may encounter various complex operating environments, so it is crucial for suppliers to provide timely and professional technical support.

The technical support provided by HULK Metal includes not only operational guidance, but also product improvement and customization. According to the specific needs of customers, suppliers should be able to provide customized designs and solutions to ensure that the products can perfectly adapt to different usage scenarios.

Delivery time

Time management is critical in construction and infrastructure projects. As an important equipment in the project, the delivery time of Lifting Clutch directly affects the progress of the entire project. Therefore, it is particularly important to choose a supplier who can deliver products on time.

The production capacity and inventory management capabilities of the supplier are the main factors affecting the delivery time. Suppliers with advanced production lines and flexible production plans are usually better able to meet the urgent needs of customers. In addition, the logistics capabilities of the supplier should also be taken into account, and they should be able to provide fast and safe transportation services to ensure that the products are delivered on time in good condition.

Price

Although price is not the only factor to consider when choosing a supplier, it does play an important role in the decision-making process. When choosing a Lifting Clutch supplier, customers should consider whether the price is reasonable while ensuring product quality. Too low a price may mean that the product quality is not up to standard or the after-sales service is not in place, while too high a price will increase the cost burden of the project.

Therefore, customers should compare among multiple suppliers and choose suppliers with reasonable prices and high cost performance. It should be noted that the price provided by the supplier should include all necessary services, such as technical support, transportation costs, etc., to avoid additional costs in the later stage.

After-sales service

Lifting Clutch will inevitably encounter some problems or failures during long-term use. Therefore, the quality of the supplier's after-sales service directly affects the service life of the equipment and customer satisfaction. Excellent suppliers should provide comprehensive after-sales services, including product repairs, parts replacement, regular maintenance, etc.

In addition, the supplier should have 24/7 customer service response capabilities and be able to provide timely assistance when customers encounter problems. This can not only reduce equipment downtime, but also effectively extend the service life of the equipment and improve the customer's return on investment.

As an indispensable equipment in the hoisting process of precast concrete components, the selection and operation of Lifting Clutch is directly related to the smooth completion of the project. When choosing a supplier, customers should consider quality control, technical support, delivery time, price and after-sales service. A good supplier can not only provide high-quality products, but also provide customers with strong guarantees in technical support and after-sales service. If you need to buy Lifting clutch, please contact us.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.Spherical Head Lifting Anchor: In-depth discussion of materials, production processes, quality inspection procedures and supplier selection guide

- 2.A comprehensive introduction to Lifting Anchor

- 3.How to Choose High-Quality Shuttering Magnetic Products and Suppliers Guide

- 4.Applications and advantages of swivel hoist rings: HULK Metal provides you with safer and more flexible lifting solutions

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.