Spherical Head Lifting Anchor: In-depth discussion of materials, production processes, quality inspection procedures and supplier selection guide

As a professional manufacturer with more than 20 years of sales experience in the field of Spherical Head Lifting Anchor, HULK Metal will introduce the key elements of this product to you in detail today, including material selection, production process, quality inspection standards and how to choose the right supplier. I hope that through this article, you can have a more comprehensive understanding of Spherical Head Lifting Anchor and make a wise decision when choosing.

Introduction

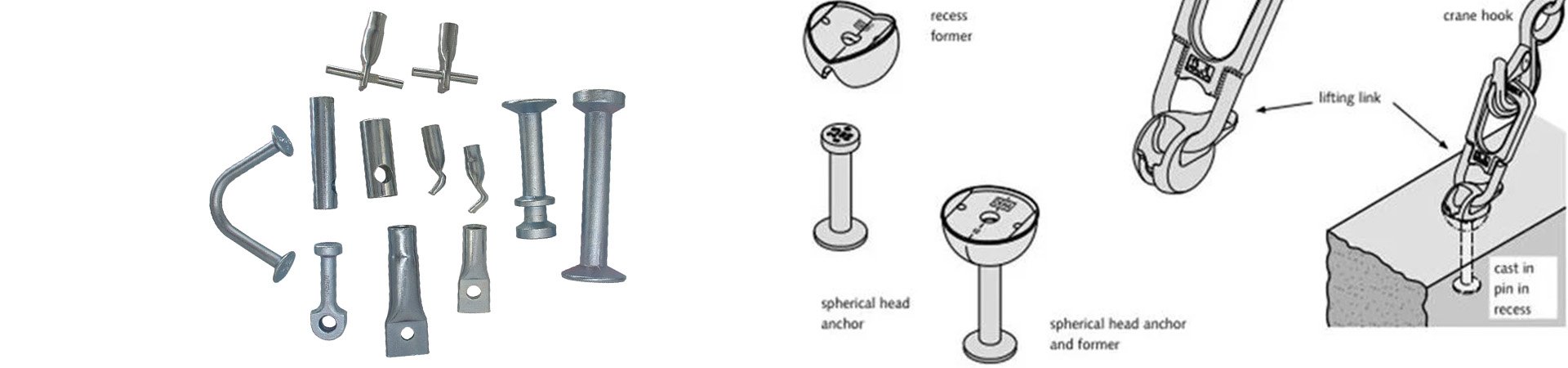

Spherical Head Lifting Anchor, also known as a dog bone lifting anchor, foot anchor or lifting pin anchor, is a lifting anchor widely used in the precast concrete industry. Its design is simple but powerful, mainly consisting of a round steel rod, a forged spherical head, and a foot embedded in concrete. Due to its diverse forms and naming methods, the application and naming of Spherical Head Lifting Anchors in different regions around the world are also different:

Dog Bone Lifting Anchor:

It is named because of its appearance similar to the shape of a dog bone and has a high tensile bearing capacity.

Foot Anchor:

Emphasizes its foot design embedded in the concrete, providing a stable anchoring effect.

Lifting Pin Anchor:

The most intuitive naming method directly describes its function as a lifting pin.

The design and application of the Spherical Head Lifting Anchor make it an ideal choice for the lifting of precast concrete components, especially for the efficient transportation and installation of large components. The tonnage and length are printed on the anchor head, so you can quickly check to ensure that the correct length of the anchor has been installed on the device. In addition, the batch number on the base allows you to fully trace the product. Now CE certified and marked on the base.

Materials

The selection of appropriate materials is crucial to the safety and durability of the Spherical Head Lifting Anchor. HULK Metal uses the following high-quality steels to manufacture the Spherical Head Lifting Anchor, ensuring that it can maintain excellent performance in various harsh construction environments:

20Mn2

This steel is widely used in the manufacture of lifting equipment that needs to withstand high loads due to its high strength and good toughness. Its high manganese content gives it excellent wear resistance and impact resistance and is particularly suitable for heavy-duty environments.

Q345D

A low-alloy high-strength steel, Q345D is known for its excellent strength and impact resistance, especially at low temperatures, so it is widely used in bridges, ships, heavy machinery, and other fields. As the material of the Spherical Head Lifting Anchor, it can ensure safety in extreme environments.

CM490

This material has excellent tensile strength and toughness, suitable for demanding construction and infrastructure projects. Its corrosion resistance also makes it widely used in marine environments and areas with severe chemical corrosion.

Stainless steel

For projects that require additional corrosion protection, the stainless steel Spherical Head Lifting Anchor is the best choice. It is not only durable but also able to maintain its strength and safety for a long time in harsh environments such as moisture, chemicals, and salt spray.

In addition to standard materials, HULK Metal can also provide customized material solutions according to the special needs of customers to ensure that the product fully meets the requirements of specific projects.

Production process

The production of Spherical Head Lifting Anchor involves a series of complex process flows to ensure that each anchor has excellent mechanical properties and high reliability. The specific production process depends on the different equipment capabilities. HULK Metal strictly follows industry best practices and uses the following key steps to produce Spherical Head Lifting Anchor:

Hot Forging Process

The core of the Spherical Head Lifting Anchor is completed through the hot forging process. Hot forging is to heat the metal material to a state of plastic deformation at high temperature, and then use pressure equipment to shape it. The advantage of this process is that the internal structure of the material is improved through forging, making it stronger and more durable. In addition, no welding or threading is required during the forging process, which avoids possible weaknesses and ensures the overall strength and load-bearing capacity of the product.

During the hot forging process, high-strength manganese steel is first heated to the appropriate temperature and then shaped through precision molds to form the spherical head and foot of the anchor. The spherical head can be perfectly combined with the lifting ear, while the foot can be embedded in the concrete to form a stable anchoring effect.

Surface Treatment

In order to improve the durability and corrosion resistance of the Spherical Head Lifting Anchor, HULK Metal usually performs surface treatment on the product. These treatments include hot-dip galvanizing, electro-galvanizing, etc. to meet the needs of different environments.

Hot-dip galvanizing

Its advantage is that the zinc layer is thicker, usually between 50 and 100 microns, providing excellent corrosion resistance, especially suitable for harsh environments such as moisture and salt spray. Hot-dip galvanizing also has a long service life, usually up to decades, and can still provide good protection when the coating is damaged.

Electro-galvanizing

A thin layer of zinc is formed on the surface of the anchor by electrolysis, with a thickness generally between 5 and 15 microns. The advantage of electro-galvanizing is that it has a smooth surface and beautiful appearance, and is suitable for occasions with high requirements for surface finish. Although its anti-corrosion ability is not as good as hot-dip galvanizing, electro-galvanizing can provide sufficient protection indoors or in less corrosive environments.

Precision Machining and Inspection

After completing hot forging and surface treatment, the Spherical Head Lifting Anchor will enter the precision machining stage. HULK Metal uses advanced CNC equipment to precisely machine each anchor to ensure that its dimensional tolerances meet industry standards. During this process, the key dimensions of the product are strictly tested to ensure that it can perfectly match the relevant equipment and workpieces in actual use.

Quality Control

HULK Metal has extremely strict quality requirements for Spherical Head Lifting Anchor. All products must undergo a strict quality inspection process to ensure that they can withstand the expected load and maintain stable performance during construction. The following are the main quality control measures we implement during the production process:

Raw Material Inspection

All raw materials used to produce Spherical Head Lifting Anchors are strictly inspected before entering the production line. We will conduct comprehensive inspections on the chemical composition, mechanical properties, surface quality, etc. of the steel to ensure that it meets international standards.

Production Process Monitoring

During the production process, we implement full-process quality monitoring. Every forging, processing, and surface treatment step is supervised by professional technicians to ensure that the process meets the standards. We also randomly select samples for strength testing and dimensional inspection to ensure that the qualified rate of each batch of products reaches 100%.

Finished Product Inspection

Before the product leaves the factory, all Spherical Head Lifting Anchors must undergo a final inspection. We will use random inspections to inspect the Lifting Anchor, which include appearance inspection, size inspection, hardness test, and load test. For key projects, we also provide third-party testing and certification services to ensure that the product meets the various standards required by the project.

How to choose a suitable supplier

Choosing a reliable Spherical Head Lifting Anchor supplier is crucial to ensure the smooth progress of the project. There are many suppliers in the market. How to choose a supplier with rich experience, reliable product quality, and high-quality service? We analyze it for you from the following perspectives:

Types of suppliers

Suppliers with inventory:

Reflected in his inventory capacity, they often have a large amount of inventory to cope with your urgent and large-volume order purchases. This kind of supplier will incur certain costs such as warehousing costs, capital costs, etc., and these costs will be included in the unit price of the ball head lifting anchor, resulting in price increases. So when your needs are more urgent, it is more appropriate to choose a supplier with inventory.

Suppliers without inventory:

Reflected in his production capacity and factory management capabilities, they often have sufficient factory resources to cope with the production schedule after receiving the order. Through this flat management, the production of multiple orders can be started at the same time, and even if there is no inventory, a certain amount of goods can be delivered in a shorter time. Because there is no restriction on capital retention cost, storage cost, and time cost, the unit price of the ball head anchor is lower. Therefore, for non-urgent orders, it is more appropriate to choose a supplier without inventory and factory resources.

Supplier's manufacturing capabilities

It is crucial to understand the supplier's manufacturing capabilities. Suppliers with complete production lines and advanced equipment can ensure stable product quality and on-time delivery. Choosing suppliers with rich production experience and modern production equipment can greatly improve the safety and efficiency of the project.

Supplier's quality control system

Quality is the key to the success of a project. It is crucial to choose a supplier with a complete quality control system. By understanding its raw material procurement, production process, quality inspection process, etc., you can judge whether the supplier has the ability to provide high-quality products. Formal suppliers usually provide product quality inspection reports to ensure that each batch of products meets the standards. Our Lifting anchors are CE-certified, and each product is printed with the CE mark.

Supplier Customer Service

High-quality customer service is also an important consideration when choosing a supplier. A supplier that can respond to customer needs in a timely manner and provide after-sales support can help you solve various problems during the project implementation, thereby ensuring the smooth progress of the project.

Advantages of HULK Metal

As a leading Chinese supplier of Spherical Head Lifting Anchor, HULK Metal has won the trust of many customers around the world with its rich experience and excellent product quality. Here are some advantages of choosing us as a partner:

As a factory specializing in Lifting Anchor manufacturing, we stand out in the industry with first-class production technology and a strict management system. We always adhere to the principle of quality first to ensure that every product meets international standards and meets the high standards of customers.

Strict quality management system

We have passed a number of international certifications such as ISO 9001, ISO 45001 and ISO 14001 to ensure that we have reached the global leading level in quality management, environmental management and occupational health and safety management. These certifications are the guarantee for our strict implementation of standards in the product manufacturing process to ensure that customers get high-quality, safe and reliable products.

Rich industry experience

With more than 20 years of industry experience, we serve customers in many countries and regions around the world, covering a variety of fields such as construction, infrastructure and heavy engineering. We have a deep understanding of the changes in demand in the global market, can quickly respond to customers' personalized needs, and provide customized solutions to help customers succeed in their projects.

Flexible order processing capabilities

We have strong production capabilities and flexible order processing systems. Whether it is mass production or small orders, we can meet the needs of customers. Especially for small and medium-sized projects, we offer highly competitive prices, providing customers with significant cost advantages, ensuring that each project can be executed efficiently and keep the budget under control.

Strict quality inspection process

In order to ensure that every Spherical Head Lifting Anchor shipped out of the factory has excellent quality, we implement a comprehensive quality inspection process. The quality inspection covers every link from raw material warehousing, processing, and manufacturing, surface treatment to finished product delivery. We have professional testing equipment and technicians to ensure that the products can function stably and reliably under various working conditions. We are committed to providing customers with products that meet the highest standards and ensure their excellent performance in the project.

Whether it is project planning, order execution, or after-sales service, HULK Metal always maintains efficient response to ensure that your needs are met in a timely manner. By cooperating with us, you will get not only product support, but also the guarantee of project success. We look forward to working with you to jointly promote the smooth completion and long-term development of the project.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.