How to choose a reliable precast magnet supplier?

Introduction

Precast Magnet is a new type of building material, widely used in precast concrete formwork systems such as construction sites, high-rise development projects, and railway infrastructure projects. The production and application of Precast Magnet is just right, playing a new role in the production of precast concrete components, replacing traditional bolt connections and welding on platforms.

Common materials

Q235A carbon steel

Q235A carbon steel is a cost-effective formwork material with excellent magnetic flux performance, which enables magnets to provide stronger adsorption. This material is low in cost and has significantly improved corrosion resistance after professional surface treatment.

Stainless steel

Stainless steel formwork is suitable for special application scenarios that require additional corrosion resistance. Although the magnetic flux is slightly inferior to Q235A carbon steel, it performs well in high humidity or corrosive environments.

Surface treatment process:

HULK Metal uses the blackening process as the standard anti-rust treatment method. Blackening treatment effectively isolates air and prevents metal oxidation by generating an oxide film on the surface of the formwork, while improving the durability and aesthetics of the product. This process combines economy and functionality, providing customers with longer service life and lower maintenance costs.

Maintenance Tips

Operating Temperature

Conventional integrated magnets usually use N-grade NdFeB magnets, whose maximum operating temperature is 80°C. Therefore, the magnets should be used at room temperature, while standard box magnets are generally used in the production of prefabricated parts. If your working environment requires special temperature conditions, please contact us in advance. We can customize magnets that meet higher temperature requirements according to needs, and the temperature range can range from 80°C to 150°C or even higher.

Avoid severe impact and drop

It is forbidden to use hard objects (such as hammers) to hit the magnetic box body, and avoid dropping it from a high place onto a hard surface. Such operations may cause the magnetic box shell to deform, the buttons to get stuck, and even damage the exposed magnets, causing the magnets to be misaligned and unable to work properly. During installation or removal, a professional release lever should be used to release the buttons. If necessary, tools can be used to knock. A wooden hammer or a rubber hammer is recommended to ensure the safety and function of the equipment.

Avoid unnecessary disassembly

The fastening nut in the button should always be kept tight and only tightened for maintenance. If the nut is loose or not tightened, it may cause insufficient contact between the magnet and the steel mold surface, significantly reducing the adsorption force of the magnetic box, which may cause the mold to slide or move, resulting in deviations in the size of the prefabricated part.

Precautions for using strong magnets

Because the magnets used have strong magnetic force, be careful when operating. Avoid placing the device close to precision instruments or other electronic equipment that is susceptible to magnetic force. At the same time, it is strictly forbidden to put your hands or arms into the gap between the magnet and the steel plate to prevent injury.

Cleaning and inspection

The surface of the magnet on the magnetic box and the steel mold should be kept flat. Before each use, the surface of the magnetic box should be cleaned as much as possible to ensure that there is no concrete residue and debris to avoid affecting the performance of the magnet.

Maintenance

After the magnet is used, it is recommended that it be removed regularly and stored properly for necessary maintenance. Maintenance includes cleaning, rust prevention, and lubrication to ensure that the magnet can maintain its optimal performance when it is used next time.

Why choose HULK Metal as your precast concrete magnet supplier?

Perfect quality control system

HULK Metal has a strict quality control system, including comprehensive quality inspection documents, advanced testing equipment, and professional quality inspection personnel. We strictly control the raw materials entering the factory, the production process, and the finished products leaving the factory at each stage to ensure that each product meets high standards. We are committed to maintaining the quality of our products above 99%, and we can provide customized services according to the special needs of customers to ensure that the specific requirements of different customers are met.

Abundant inventory and fast delivery

The company provides a variety of styles of precast concrete magnets and supports customized services. We have sufficient inventory to respond quickly to customer needs, ensure rapid production and delivery, while ensuring product quality, and provide customers with high-quality choices at very competitive prices.

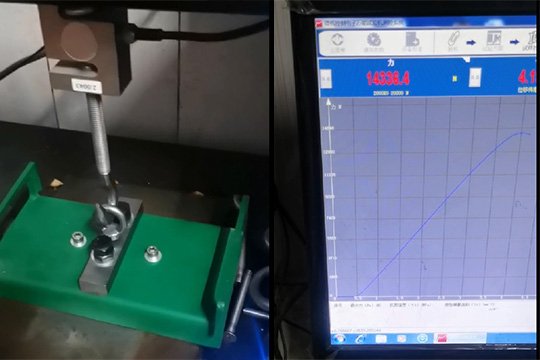

Strict quality control

We strictly check each magnet to ensure that its suction meets the standard and meets high-quality requirements. Each product is carefully tested to ensure its excellent performance when used.

Professional packaging service

Our precast concrete magnets will be packed in double-wall corrugated boxes and tied with sturdy strapping tape. High-quality foam boards are placed inside the carton and between the magnets to effectively isolate and protect the magnets from scratches and damage.

Shipping Methods and Packaging Options

Sea Shipping

Two sea shipping packaging options are available:

1.1 Pallet Packaging

1.2 Sturdy Wooden Box Packaging

Air Shipping

Transported by air carriers such as FedEx, DHL, UPS, and TNT. Since magnetic items can interfere with the safety of aircraft transportation, we will conduct magnetic detection for each magnetic item and use anti-magnetic treatment to ensure that the magnetic force meets air transportation standards. During the packaging process, we will insert thick iron sheets or iron boxes between the foam and the carton wall to ensure transportation safety.

Other Precast Concrete Accessories

The lifting system is a safe, effective, quick connection and disconnection system for handling and transporting precast concrete structures. Fast, safe, and affordable. It is a non-welding system, and all lifting anchors are made of high-quality, high-quality, and reusable hot-forged steel. The safe load rating of the bolt lifting system is 1 to 32T. Each element has a clearly marked maximum safe working load for lifting the precast concrete component from a horizontal to a vertical position without the help of a tilting table. For each batch, we will carry out strict inspections, including raw material quality inspection, semi-quality inspection, product quality inspection, and possible tolerance and deviation inspections. For each bolt expander, we will carry out a full test according to the specified load safety factor.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.