Inserts Magnetic

Description:

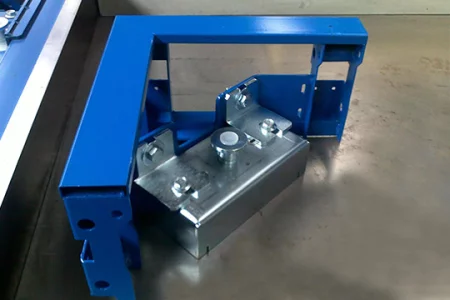

Screw M8, M10 is good choice to fix different type sockets and the holding force 30KGS is enough to fix the parts,make it positioning,no slipping.

Choose high-quality inserts magnets

The inserts magnetic,is made of Neodymium Magnet,steel armature and steelthread rod.

The neodymium magnet is plated with NI-CU-NI treatment,the steelarmature is treated with Zinc coating,

the thread rod is coated with black epoxy.These surface treatment could offer good anti corrosion protections for the bushingfixing magnets

The inserted fixing magnet consists of Cup Magnet /base magnet and a separablethread rod.

Professional processing technology

To make sure the adequate pull force,The strongest Permanent Magnet-NdFeB magnets are used in the embeded socketfixing magnet.

The NdFeB Magnet are plated with NiCuNiand the metal cup could beplated with color Zinc or other treatments to well protect the metal cup from corrosion.

The inserts magnetic contact surface should be clean and flat otherwise the actualmagnetic force will be reduced.

The max working temperature of the embeded fixingmagnets is 80 degrees.

Please keep the embeded fixing magnets away fire or beingheating.If higher working temperature is needed,

the higher grade NdFeB magnetswill be necessary then.The magnetic force and sizes could be designed according tocustomers'requirements.

Wide range of applications

It can be used to fix the connections between floor slabs and beams and columns to enhance the stability of the building structure. Secondly, the fixed magnetic base can also be used to fix the connection between the wall panel and the floor, making the entire building stronger and safer. In addition, the inserts magnetic base can also be used to fix the arch structure of precast concrete components to improve the aesthetics and artistry of the building.

Dimensions and Tolerances of HULK Metal Precast Magnets

Standard Magnetic Fixing Plate | |||

part Code | Thread M/Rd | Diameter(mm) | Height(mm) |

M8 | 8 | 40 | 12 |

M10 | 10 | 40 | 12 |

M12 | 12 | 60 | 12 |

M16 | 16 | 60 | 12 |

M20 | 20 | 60 | 12 |

M24 | 24 | 74 | 12 |

M30 | 30 | 90 | 12 |

M36 | 36 | 90 | 12 |

M42 | 42 | 11.5 | 15 |

M52 | 52 | 135 | 15 |

Features of HULK Metal Precast Magnets:

-

Design Principles of HULK Metal Fixing Magnets:

HULK METAL's insert magnets are specifically engineered for application within PVC pipe systems and embedded bellows. These magnets serve to effectively secure embedded components, preventing undesired movement such as sliding or slipping. Renowned for their durability, cost-effectiveness, user-friendly nature, and high efficiency, our products offer reliable performance in various scenarios. Additionally, we accommodate special size and shape requests to meet unique project requirements.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

The Composition Of HULK Metal Fixing Magnets:

The Round fixing magnet,is made of Neodymium Magnet,steel armature and steelthread rod.The neodymium magnet is plated with NI-CU-NI treatment,the steelarmature is treated with Zinc coating,the thread rod is coated with black epoxy.These surface treatment could offer good anti corrosion protections for the bushingfixing magnets.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Installation of HULK Metal Fixing Magnets:

(1) The platform for using the inserts magnetic should be kept clean and flat to prevent iron pins or concrete slurry from entering the inside of the inserts magnetic,

which will affect the flexibility of the switch. At the same time, it may cause the magnetic block to tilt and cannot be leveled for service. platform.

(2) The suction surface of the inserts magnetic should be kept clean and leveled continuously. If it is not needed for a long time, the suction surface should be oiled and treated to prevent rust.

You should always check whether the magnet can fit flatly into the platform and whether the switch is flexible and easy.

(3) During the use of the inserts magnetic, avoid hitting or scratching it with iron tools, which may cause the iron can to deform or even damage the magnet,

so as not to affect the performance indicators. If you must use special tools, it is recommended to use a vulcanized rubber hammer to tap gently.

(4) The magnetic force on the holding surface of the magnetic box is very strong. You should avoid getting close to instruments,

machinery and electronics and other components that are susceptible to magnetic damage. At the same time, do not get close to other iron materials.

Once they are attracted, they cannot be separated. . It is recommended to make special auxiliary tools to place the magnetic box and other magnetic fixing splints.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Maintenance of HULK Metal Fixing Magnets:

1. To prevent damage to the inserted magnet, refrain from subjecting it to impacts or using hard tools for manipulation.

2. Ensure that the contact surface remains clean and smooth at all times.

3. Following usage, it is imperative to clean the inserted magnets.

Maintain a maximum working and storage temperature below 80°C, and ensure the absence of corrosive substances in the vicinity.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

OtherLifting Anchors You Might Want to Know

Besides wire precast magnets, we also provide Lifting Clutch, Spread Anchors, Spherical Head Lifting Anchors, Lifting Sockets, and Recess Formers. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Precast Magnets in Blogs

Here is the introduction, production, and quality inspection of the precast magnet that we can organize, as well as some sharing from customers and details of our delivery. You can message us to share or get some content about precast magnets.

-

January 31, 2024Precast Concrete Factory Tells You Why Choose Electric Box Fixing Magnets?

January 31, 2024Precast Concrete Factory Tells You Why Choose Electric Box Fixing Magnets?The electric box fixing magnets emerges as a transformative solution, offering many advantages such as stability, flexibility, ease of use and cost savings.

-

November 16, 2023Precast Magnets: Revolutionizing Formwork Fixation

November 16, 2023Precast Magnets: Revolutionizing Formwork FixationThe magnetic box stands out as a specialized magnetic fixing device designed explicitly for securing precast concrete formwork.

-

November 09, 2023Shuttering Magnets: The Pinnacle of Precast Concrete Formwork Solutions

November 09, 2023Shuttering Magnets: The Pinnacle of Precast Concrete Formwork SolutionsShuttering magnets represent a remarkable innovation in the realm of precast concrete construction.

Reviews

-

Diego Nanini

Earnest is very responsive. The product delivered on time and received in good condition.