Precast Magnets: Revolutionizing Formwork Fixation

Article Guidance:

Ⅱ.Considerations for Optimal Performance:

Ⅲ.Best Practices for Operating Precast Magnets:

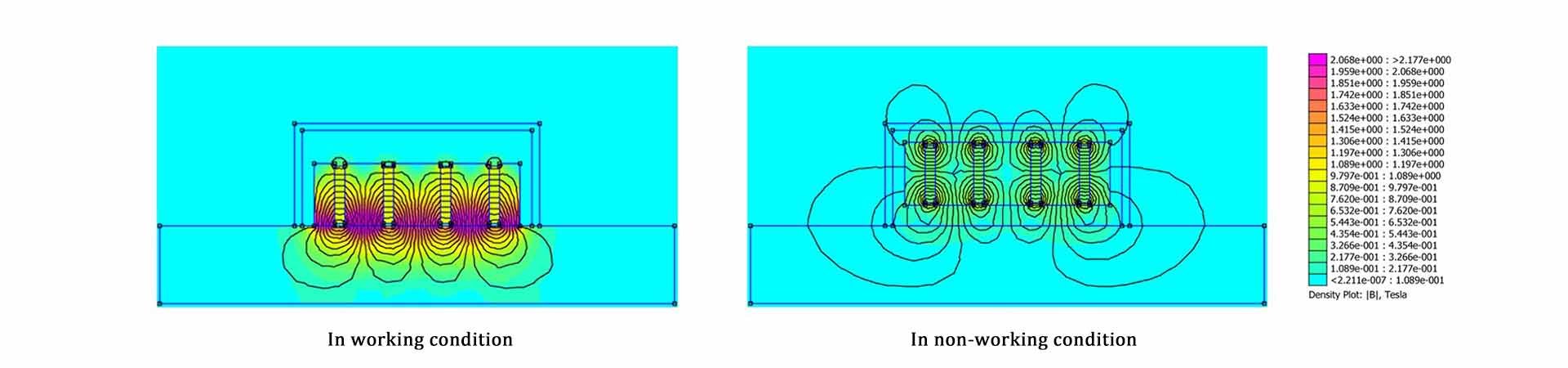

The magnetic box stands out as a specialized magnetic fixing device designed explicitly for securing precast concrete formwork. In contrast to conventional mechanical fixing techniques like screws and nuts, this innovative magnetic box fixation method eliminates the need for drilling or welding. Notably, it offers a non-intrusive solution that safeguards the integrity of the formwork, ensuring it remains intact throughout the construction process.

Ⅰ.Key Advantages:

1.1. Non-Destructive Fixation: One of the standout features of the magnetic box is its ability to secure formwork without causing any damage. Traditional methods such as drilling and welding can compromise the structural integrity of the formwork, leading to potential issues during construction.

1.2. Efficient Installation: the magnetic box's robust suction force plays a pivotal role in streamlining the formwork installation process. By eliminating the need for time-consuming drilling or welding, it significantly reduces the overall process and time required for formwork setup.

1.3. Enhanced Work Efficiency: With its powerful magnetic force, the fixing device not only accelerates the installation but also enhances overall work efficiency. Construction teams can leverage the quick and secure attachment provided by the precast magnets to expedite the precast concrete component production.

Ⅱ.Considerations for Optimal Performance:

2.1. Usage Scenario:

When embarking on the selection process for a magnetic box, it is crucial to carefully consider the specific usage scenario. Different types of formwork, such as fixed mold tables or vibrating mold tables, demand distinct characteristics from the magnetic box. Understanding the nature of the construction environment and the type of formwork involved is essential to ensure the chosen magnetic box is well-suited for its intended application.

2.2. Spacing of Steel Bars:

The spacing of steel bars within the precast concrete components plays a pivotal role in the selection of an appropriate magnetic box. To guarantee optimal performance, it is imperative to choose a magnetic box that aligns with the spacing configuration of the steel reinforcement. This consideration ensures that the magnetic force is evenly distributed across the formwork, preventing any weak points or uneven fixation.

2.3. Working Temperature:

Another critical factor to take into account is the working temperature of the construction site. Magnetic boxes may exhibit variations in performance under extreme temperature conditions. It is essential to select a magnetic box that can maintain its magnetic strength and overall functionality within the anticipated temperature range of the construction environment. This ensures consistent and reliable performance, regardless of the external conditions.

2.4. Mold Height (Component Thickness):

The mold height, corresponding to the thickness of the precast concrete component, directly influences the selection of an appropriate magnetic box. To achieve optimal fixation, it is essential to match the suction force and size of the magnetic box with the specific mold height requirements. A careful assessment of the components being produced and their varying thicknesses enables the selection of magnetic boxes that cater to the diverse needs of the construction project.

2.5. Customization for Efficiency:

Selecting a magnetic box that aligns with the unique parameters of the construction project fosters efficiency and precision. Customization options, which may include adjustable suction force and variable sizes, allow for a tailored approach. This ensures that the magnetic box not only meets the immediate needs of the project but also offers versatility for potential future applications.

Ⅲ. Best Practices for Operating Precast Magnets:

3.1. Preventing Deformation:

During the operation of precast magnets, it is paramount to avoid any form of deformation resulting from impacts, knocks, or contact with hard tools. Deformation can compromise the structural integrity of the magnetic box and, subsequently, hinder its performance. Careful handling and adherence to proper operating procedures are essential to prevent deformities that may arise from accidental mishandling.

3.2. Surface Cleanliness and Flatness:

Maintaining the cleanliness and flatness of both the magnetic box's holding surface and the usage platform is critical for sustained functionality. The bottom of the magnetic box, which makes contact with the formwork or work platform, should be free from contaminants such as iron filings or concrete slurry. Any foreign particles entering the magnetic box can impact the flexibility of the internal components, particularly the switch mechanism. Additionally, a clean and flat surface ensures that the magnet blocks fit flush to the platform, maximizing the work suction force.

3.3. Preventing Contaminant Ingress:

Iron filings or concrete slurry entering the magnetic box can have adverse effects on its internal components. These contaminants may compromise the flexibility of the switch mechanism, impeding its ability to function smoothly. Furthermore, the intrusion of foreign particles can lead to the tilting of the magnet blocks, preventing them from fitting securely and flatly to the platform. This not only reduces the overall work suction force but can also create uneven fixation, impacting the stability of the formwork.

3.4. Regular Maintenance Checks:

To ensure consistent performance, regular maintenance checks are recommended. These checks should include a thorough inspection of the magnetic box for any signs of deformation, cleanliness of surfaces, and potential ingress of contaminants. Addressing any issues promptly can prevent operational disruptions and extend the lifespan of the magnetic box.

3.5. Adherence to Operating Guidelines:

Following the manufacturer's operating guidelines is fundamental to the longevity and efficiency of the precast magnets. Users should be familiar with recommended practices and procedures outlined in the product documentation. This includes guidelines on handling, storage, and maintenance to guarantee the optimal performance of the magnetic box throughout its operational life.

The formwork fixing magnetic box emerges as a game-changing innovation in the realm of precast concrete construction. Its non-destructive fixation, efficient installation process, and overall improvement in work efficiency position it as a valuable tool for construction teams aiming to enhance productivity while maintaining the integrity of their formwork structures. As the construction industry continues to evolve, the magnetic box stands as a testament to the importance of innovative solutions in driving progress.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.