Everything You Need to Know on Precast Concrete Magnets

In the world of construction, efficiency, precision, and reliability are paramount. Traditional methods often slow down progress and increase costs, leading many professionals to seek innovative solutions that can deliver enhanced performance without sacrificing quality. Enter Precast Concrete Magnets — a groundbreaking technology that simplifies the assembly of formwork systems in precast concrete production. Whether you're dealing with high-rise buildings, railway infrastructure, or any large-scale project, these magnets offer a game-changing approach to streamline your workflow.

In this detailed guide, we will explore everything you need to know about Precast Concrete Magnets, including their design, functionality, selection criteria, and benefits. This comprehensive resource will provide you with a deeper understanding of why HULK Metal's Precast Concrete Magnets are the ideal solution for your next project.

What Are Precast Concrete Magnets?

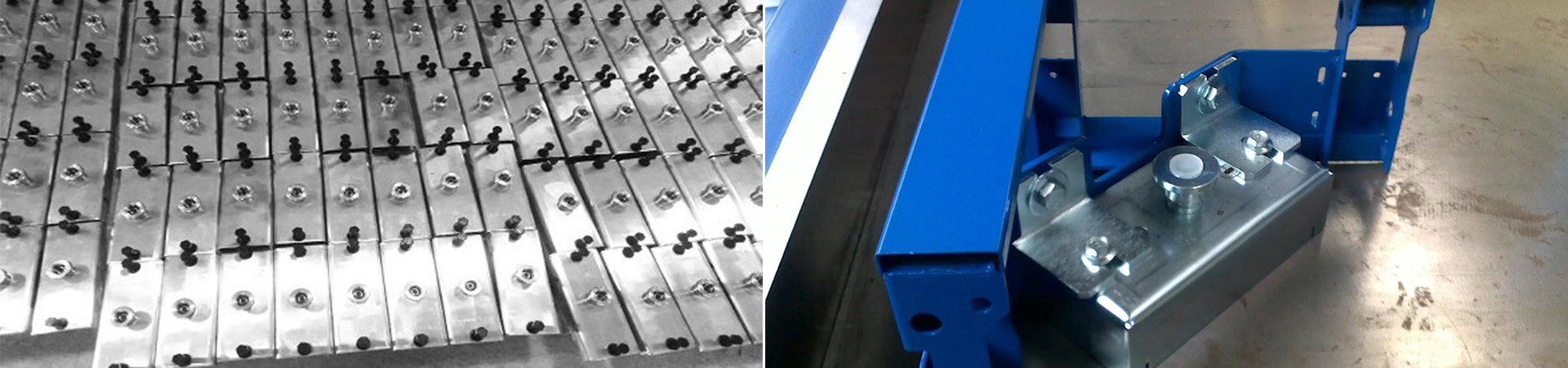

Precast Concrete Magnets, also referred to as magnetic boxes, button magnets, or shuttering magnets, are specialized magnetic devices used to secure formwork systems in the production of precast concrete elements. These magnets are critical in stabilizing and aligning the formwork during the concrete pouring process, ensuring precision and uniformity in the final product.

These magnets are highly versatile and can be applied to various materials, including steel, wood, and aluminum formworks, making them indispensable in modern construction practices. Precast Concrete Magnets offer a robust, reusable solution that enhances productivity by reducing setup time and minimizing human error.

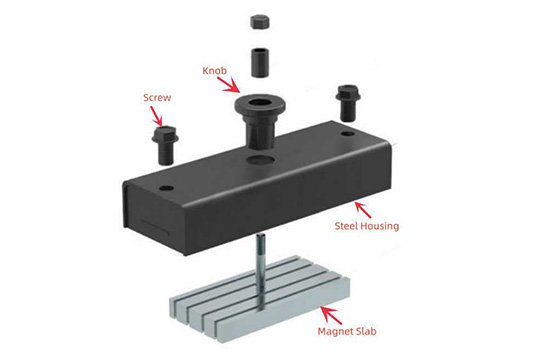

Components of Precast Concrete Magnets

Precast Concrete Magnets are composed of several key components, each contributing to their overall performance and durability:

NdFeB (Neodymium-Iron-Boron) Magnets:

The heart of the system, these magnets offer the highest magnetic strength available. They provide a reliable and secure hold on the formwork, ensuring it remains in place during the entire casting process.

Steel Housing:

A sturdy outer shell encases the magnet system, offering protection and durability. The steel housing helps to withstand the rigorous conditions on construction sites, such as mechanical impact and exposure to elements.

Magnetic Plate:

The magnetic plate works in conjunction with the NdFeB magnets to ensure an even distribution of magnetic force. This component plays a crucial role in maintaining the secure attachment of formwork, preventing slippage or misalignment.

Knob (On/Off Button):

The knob allows for easy activation and deactivation of the magnetic force. This feature enhances ease of use, as workers can quickly engage the magnets when positioning the formwork and disengage them when removing it.

How Precast Concrete Magnets Work

Precast Concrete Magnets operate by harnessing the magnetic force generated by the NdFeB magnets. The steel housing directs the magnetic field, allowing the magnet to securely attach to the steel base of the formwork. When the formwork is in place, the magnets ensure that the structure is stable and aligned during concrete pouring, preventing any movement that could compromise the final product.

Once the concrete has set and the formwork needs to be removed, the magnetic system can be easily disengaged using the on/off button. This simple mechanism not only speeds up the formwork removal process but also ensures the magnets are reusable, providing significant cost savings over time.

Why Choose Precast Concrete Magnets?

Precast Concrete Magnets are a superior alternative to traditional mechanical fastening methods. They offer several advantages that make them an essential tool in the modern construction industry:

Time Efficiency:

The quick engagement and disengagement of magnets drastically reduce the time required to set up and remove formwork. This efficiency leads to faster project completion times.

Improved Precision:

Magnets ensure a higher level of accuracy in formwork alignment. This precision is critical in achieving consistent and high-quality precast elements.

Durability and Reusability:

Precast Concrete Magnets are designed to withstand the harsh conditions of construction sites. Their robust design ensures longevity, while their reusable nature makes them a cost-effective solution.

Safety:

By eliminating the need for traditional fastening methods that require drilling or bolting, magnets reduce the risk of accidents and injuries on-site.

Factors to Consider When Choosing Precast Concrete Magnets

When selecting Precast Concrete Magnets for your project, several factors must be considered to ensure optimal performance:

Magnetic Strength

The magnetic strength of the product must match the load-bearing requirements of the formwork. The strength of the NdFeB magnets is crucial in maintaining a secure connection, particularly in applications involving heavy concrete elements.

Durability of Components

Given the demanding nature of construction environments, it's essential to choose magnets with durable steel housing that can withstand impact and environmental factors. The magnet system should also resist demagnetization over time to maintain its performance.

Compatibility with Formwork Material

Not all formwork materials are created equal. Precast Concrete Magnets must be compatible with the type of formwork you're using, whether it is steel, aluminum, or wood. Ensuring this compatibility will guarantee optimal holding power.

Ease of Use

The on/off functionality should be user-friendly, allowing workers to engage and disengage the magnets quickly and efficiently. This factor is essential to minimize downtime during installation and removal of formwork.

Cost-effectiveness

While initial investment costs in magnets might be higher than traditional methods, the long-term benefits of reusability and faster project turnaround times lead to significant cost savings.

Applications of Precast Concrete Magnets

Precast Concrete Magnets are widely used in various construction sectors. Some of the most common applications include:

Railway Infrastructure Projects

Precast Concrete Magnets are often used in railway infrastructure, where precise and durable concrete elements are required for tracks, bridges, and platforms.

High-rise Buildings

In high-rise construction, the need for accurate and strong formwork systems is paramount. Precast Concrete Magnets provide the necessary stability and precision to create consistent structural elements.

Precast Concrete Panels

Magnets are ideal for producing large-scale concrete panels used in the construction of walls, facades, and other structural components.

Civil Engineering Projects

From bridges to tunnels, Precast Concrete Magnets are crucial in ensuring that formwork systems remain secure during the casting process.

Benefits of Using HULK Metal's Precast Concrete Magnets

At HULK Metal, we pride ourselves on delivering top-quality precast concrete magnets engineered for superior performance. Our products offer several key benefits, including:

High Magnetic Strength

Our magnets use the latest NdFeB technology to ensure unparalleled holding power, even in the most demanding construction environments.

Durable Construction

Our magnets are encased in high-quality steel housing that protects them from mechanical damage and corrosion, ensuring longevity.

Customizable Solutions

We offer a wide range of magnet sizes and strengths to meet the specific needs of your project. Whether you're working on a small residential building or a large infrastructure project, we have the right magnet for the job.

Exceptional Customer Support

We work closely with our clients to provide tailored solutions and technical support, ensuring that you get the most out of our products.

HULK Metal's Commitment to Sustainability

In addition to providing high-quality products, HULK Metal is committed to sustainability. Precast Concrete Magnets help reduce the environmental impact of construction projects by minimizing waste associated with traditional formwork systems. Our magnets are reusable, which reduces the need for disposable materials, contributing to a greener, more sustainable construction industry.

Precast Concrete Magnets are an essential tool in modern construction, offering unparalleled efficiency, precision, and cost savings. HULK Metal is proud to be a leader in the production of these innovative magnets, providing builders and engineers with reliable, durable, and high-performing products.

By investing in HULK Metal’s Precast Concrete Magnets, you're not just choosing a product — you're choosing a solution that will enhance the quality, speed, and sustainability of your construction projects.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.