High-Performance Lifting Loops for Safe and Economical Handling of Precast Concrete

Introduction

Lifting loops are an essential tool in the precast concrete industry, providing a reliable, cost-effective solution for lifting and transporting precast elements such as panels, stairs, and beams. These lifting loops are designed to fit into precast lifting eye sockets and provide a secure connection for the safe handling of precast concrete units. They are an integral component in many construction projects, making it easy to move heavy concrete sections while ensuring worker safety and operational efficiency.

HULK Metal, a manufacturer of precast concrete accessories known for precision engineering and commitment to quality, produces lifting loops using advanced materials and production processes. These lifting loops are certified to meet stringent safety standards. In this detailed overview, we will examine the features, safety considerations, and best practices associated with lifting loops, focusing on their construction, use, and inspection requirements.

Features of Lifting Loops

Lifting loops are constructed using a combination of high-strength steel wire and a strong steel ferrule for rugged durability. This construction ensures the loops can handle large loads while maintaining flexibility and ease of use. Key features include:

High-tensile steel wire:

The lifting loops are made from high-tensile steel wire, known for its strength and resistance to abrasion. This material choice ensures long-lasting durability even in demanding conditions.

Forged steel ferrule:

The steel wire is forged onto the steel ferrule, providing a secure connection that maximizes load-bearing capacity. The ferrule also helps prevent the wire from deforming during lifting operations.

CE Certification:

All lifting loops manufactured by HULK Metal are CE-certified, indicating compliance with European safety standards. This certification guarantees that the lifting loops have been rigorously tested to ensure safety and performance.

ISO 9001 Certified Production:

Our factory is ISO 9001 certified, meeting international quality management standards, and ensuring consistent product quality and reliability.

Safety Factor:

Each lifting loop has a safety factor of 5:1, meaning it can handle loads five times greater than the Working Load Limit (WLL) under standard operating conditions.

Metric and Rd Threads:

The loops are available in both Metric and Rd thread options, making them compatible with a wide variety of lifting sockets.

Basic Instructions

The proper use of lifting loops is essential to ensure the safety and integrity of the lifting process. Some basic guidelines include:

Threading lifting loops into lifting sockets:

Before each use, the lifting loop should be fully threaded into the lifting socket until it bottoms out. If debris or dirt is impeding this, the threads should be cleaned before reinserting the loop.

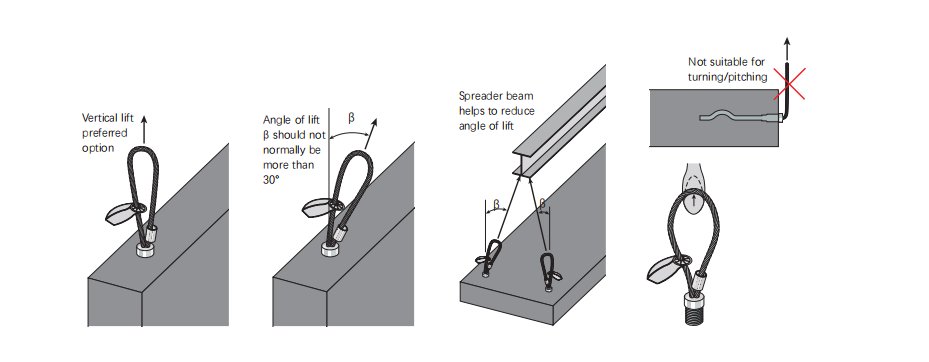

Angle of Use:

The lifting loops are designed to be used at angles up to 45 degrees. Using the lifting loop at a greater angle may damage the ferrule and over-tighten the wire, causing breakage. The lifting loop should not be used at an angle greater than 45 degrees, and care should be taken to ensure that the lifting loop angle is within the manufacturer's recommended range.

Replacing Damaged Loops:

Any lifting loop that shows signs of damage, such as broken wires, kinks, or corrosion, must be replaced immediately. Using a damaged unit can result in catastrophic failure and should be strictly avoided.

Concrete Strength:

Lifting rings should only be attached to precast concrete units when the concrete has reached a minimum compressive strength of 15 N/mm². This ensures that the unit can withstand the forces applied during lifting without cracking or breaking.

Safety Considerations

One of the main concerns when using lifting loops is ensuring they are used correctly to prevent accidents and equipment failures. HULK Metal's lifting rings are designed with several built-in safety measures:

Performance Safety Factor:

This industry-standard safety factor ensures that the ring can carry loads well in excess of its rated capacity under normal conditions without failure.

Marking and Identification:

Each lifting ring is clearly marked with its thread size, safe working load, and a unique identification number. This number corresponds to the CE Declaration of Conformity, allowing the user to verify the certification and performance capabilities of the product.

Inspection Requirements:

While lifting rings can be reused, they must be inspected before each use. The inspection process includes checking for signs of damage, including broken wires, kinks, thread damage, corrosion, or any other defects that could compromise the strength of the lifting ring. Lifting loops that show signs of wear should be discarded immediately to avoid the risk of failure during the lifting process.

Testing and Inspection Protocol

Lifting loops must be tested and inspected regularly to ensure continued safety and performance. Every loop manufactured by HULK Metal is test-loaded before shipment and a unique batch number is recorded with the company's QA department. This allows for traceability and verification of the product's load-bearing capacity. In addition to the initial test, lifting loops should be inspected every six months if reused and must be retested annually.

During the inspection, the following should be checked:

Wire Rope Condition:

Ensure that the wire rope is not broken, kinked, or badly worn. Any signs of loose outer layer or corrosion should be replaced immediately.

Thread Damage:

Inspect the threads for signs of wear or deformation. Damaged threads can compromise the connection between the loop and the lifting socket, increasing the risk of failure during lifting.

Ferrule Integrity:

Inspect the ferrule for any signs of cracking or deformation. The ferrule plays a vital role in securing the wire and any damage can affect the overall strength of the loop.

Limitations and Warnings

While lifting loops are versatile and very effective for most precast concrete lifting applications, there are some limitations to their use:

Not Suitable for Turning or Pitching:

Lifting loops are not intended for turning or pitching devices during lifting. Attempting to do so may place excessive stress on the loops and cause equipment failure.

Severe Repeated Use Conditions:

While lifting loops can be reused under certain conditions, they are not recommended for severe repeated use environments where they may be subject to excessive wear or severe conditions. In such cases, it is recommended that the lifting loops be replaced periodically to ensure safety.

Directions for Use and Best Practices

When using lifting loops, proper lifting procedures must be followed to ensure safety. Before each lift, check that the lifting loops are compatible with the socket or insert and that the correct unique number is marked on the lifting loops. Verify that the wires are in good condition and discard any lifting loops that show signs of damage. It is also important to follow the lifting angle guidelines and ensure that the threads are fully engaged in the socket before lifting.

If there is any doubt as to whether a lifting loop is suitable for a particular application, consult the manufacturer. HULK Metal offers expert guidance to help you select the right lifting equipment for your specific lifting needs and can provide custom solutions for challenging projects.

Lifting loops are an integral part of the precast concrete industry, providing a reliable and economical solution for lifting heavy concrete units. Their rugged construction, coupled with HULK Metal’s commitment to quality, ensures that these lifting loops can safely and efficiently handle precast elements. By following proper usage guidelines and performing regular inspections, construction professionals can maximize the performance and life of their lifting loops, ensuring the safety of workers and equipment.

In summary, lifting loops are a versatile and durable option for handling precast concrete elements, but their safety and performance depend on proper use, regular inspections, and adherence to best practices. When used properly, they can provide a cost-effective solution that improves the efficiency and safety of construction operations.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.Introduction of Precast concrete accessories Lifting System

- 2.A comprehensive introduction to Lifting Anchor

- 3.Applications and advantages of swivel hoist rings: HULK Metal provides you with safer and more flexible lifting solutions

- 4.Understanding Load Capacity: A Guide to Lifting Anchor Strength

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.