Double Wire Rope Loop Boxes

Description:

The Wire Rope Loop Box is offered in two variants: a wire rope loop box and a double wire rope loop box.

You Will Enjoy Them When You Buy Wire Loop Boxes from HULK Metal.

※ Certificate:CE,ISO9001-2015;

※ Minimum Breaking Strength:24.4KN;

※ MOQ:2,000 pieces for each size;

※ Production Capacity:30,000 pieces one day;

※ Packaging:4,000 pieces per Plywood Box or according to your requirement;

※ MaterialtHigh Strength 1770Mpa Galvanized Steel Wire Rope;

※ Delivery Time:Usually 15-30 days for one container;

※ Standard:EU Machinery Directive 2006/42/EC and VDI/BV-BS 6205.

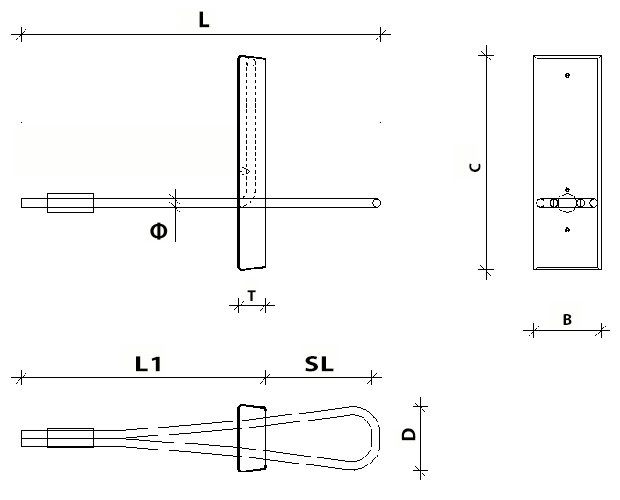

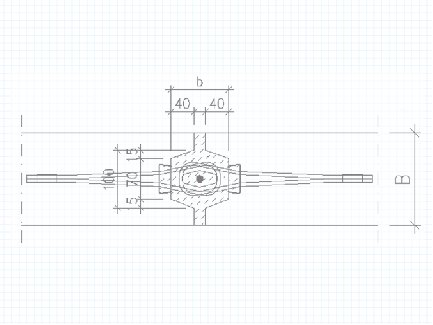

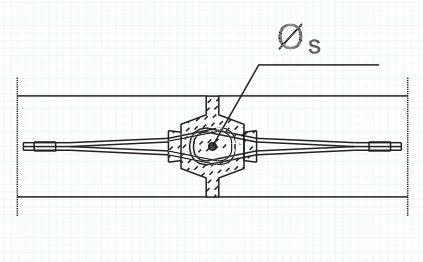

Dimensions and Tolerances of HULK Metal Wire Loop Box

| NAME | HULK Metal Wire Loop Box | ||||||||

| DRAWINGS | Types | SL [mm]±10 | L1 [mm]±10 | L [mm]±20 | C [mm]±2 | D [mm] | B [mm]±2 | T [mm]±2 | Φ [mm] |

| HM-A | 60 | 210 | 276 | 160 | 60 | 50 | 20 | 6 |

HM-B | 80 | 210 | 296 | 160 | 60 | 50 | 20 | 6 | |

HM-C | 100 | 210 | 316 | 160 | 65 | 50 | 20 | 6 | |

HM-D | 120 | 210 | 336 | 160 | 70 | 50 | 20 | 6 | |

HM-E | 140 | 370 | 528 | 200 | 100 | 70 | 30 | 8 | |

Thickness of the Steel Plate of the Box | |||||||||

0.5~0.7mm | |||||||||

Materials of the Wire Loop Box | |||||||||

Compression Sleeve | 1.0330 | ||||||||

Wire Loop | high-strength steel wire rope SE-Zn | ||||||||

Box | 1.0046 | ||||||||

Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized | ||||||||

Service | Freight consulting / Quality inspection / After-sales / Other value-added services. | ||||||||

Delivery Method | Sea / Air / Land | ||||||||

Quality Assurance | Life-Long | ||||||||

Features of HULK Metal Wire Loop Box:

-

Design Principles of HULK Metal Wire Loop Box:

l The capacities presented in the tables below are calculated for static loads. Our wire rope loops are not designed to be used for dynamic loading or for lifting. For the capacities to be achieved, there should be no cracks or deformations in the joints.

l The capacities of the wire rope loops are calculated for a joint as presented in the diagram with seam thickness and reinforcement as outlined in the following sections. The steel boxes and the seam must be fully filled with concrete.

l The capacities given are the resistances in the ultimate limit state, so please compare them to design loads.

l The resistance is defined by the weakest concrete in the joint (element/joint concrete). Resistances are calculated for concrete classes C25/30, C30/37, and C40/50.

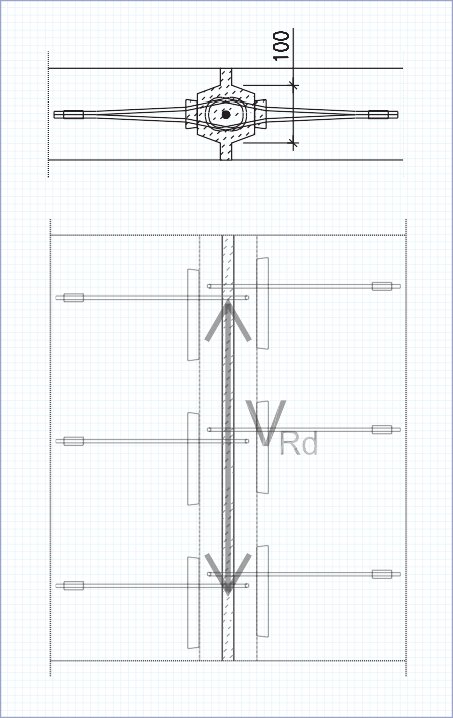

Longitudinal Shear Capacity:

Boxes Centre to Centre

Design Value of Longitudinal Shear Resistance, VRd (kN/m)

Standard

HM-A, -B, -C, -D

HM-E

C25/30

C40/50

C25/30

C40/50

250

125

159

-

-

300

117

148

-

-

350

101

128

182

230

400

89

112

163

207

450

79

100

146

184

500

72

91

131

166

550

66

83

120

152

600

60

76

110

139

650

56

71

102

129

700

52

66

95

120

750

49

62

-

-

The resistance is defined by the weakest concrete in the system, either to fill the joint or the concrete used to make the precast element.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Tensile Capacity of HULK Metal Wire Loop Box:

Capacities are shown here per box.

Box Type

Part No.

Design Value of Tensile Resistance, FRd (kN)

C25/30

C40/50

Standard

HM-A

12.9

12.9

HM-B

HM-C

HM-D

HM-E

23.1

23.1

The resistance is defined by the weakest concrete in the system, either to fill the joint or the concrete used to make the precast element. The distance between wire loop boxes must be as defined later in this section.

Transversal Shear Force:

Capacities are shown here per box.

Box Type

Part No.

Design Value of Horizontal Shear Resistance, NRd (kN)

C25/30

C40/50

Standard

HM-A

4.6

5.8

HM-B

8.2

10.3

HM-C

HM-D

HM-E

The resistance is defined by the weakest concrete in the system, either to fill the joint or the concrete used to make the precast element. The distance between wire loop boxes must be as defined later in this section.

Combined Forces:

For circumstances where there is a combination of forces on the wire loop joints, the following must apply:

VApplied / VRd = FApplied / FRd = NApplied / NRd < = 1

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

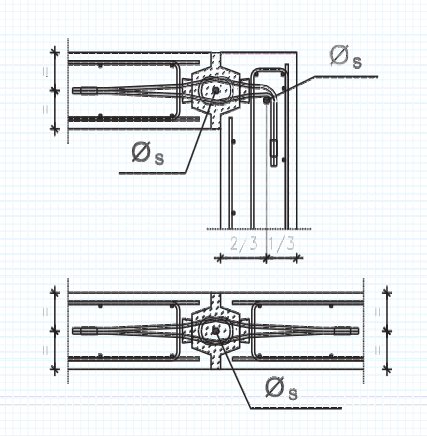

Installation of HULK Metal Wire Loop Box:

The wall elements must be reinforced according to the wall element design.

Seam Thickness:

The size of the wire rope loops must be chosen according to the thickness of the joint to enable the vertical ribbed steel bar in the joint to pass through the wire rope loops on both sides of the joint.

Box Type

Part No.

Recommended Thickness of Rope Loop Seam (mm)

Standard

HM-A

70-90

HM-B

90-110

HM-C

110-140

HM-D

140-190

HM-E

160-220

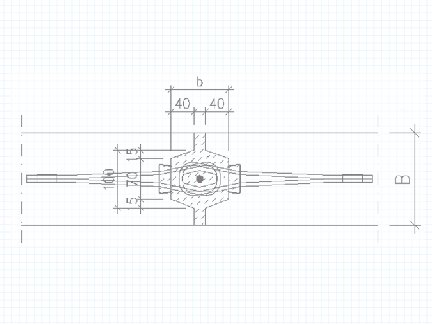

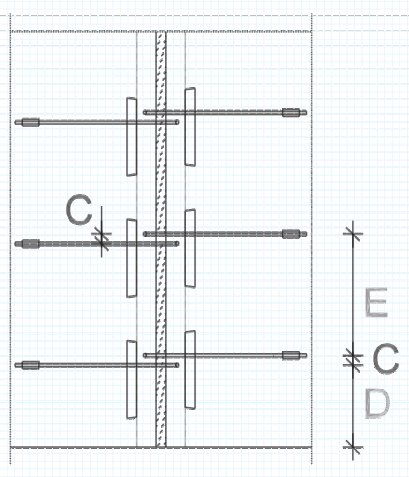

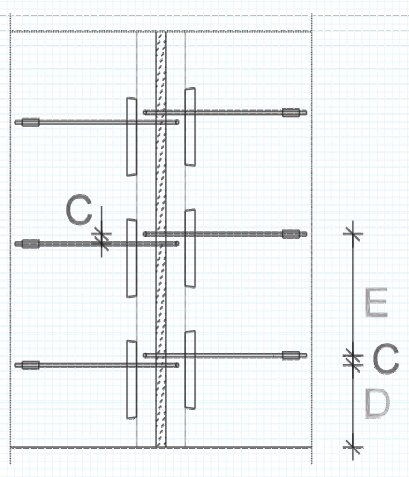

Minimum Edge Distance and Spacing:

Centre to center Emin = minimum distance between wire rope loops at the same side of the joint.

Centre to center Cmax = minimum distance between wire rope loops at opposite sides of the joint.

Minimum width Bmin = minimum total wall width.

Box Type

Part No

Centre to Centre Emin

Edge Distance Dmin

Centre to Centre Cmax

Minimum Width Bmin

mm

Standard

HM-A

250

100

20

120

HM-B

HM-C

HM-D

HM-E

350

200

25

150

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

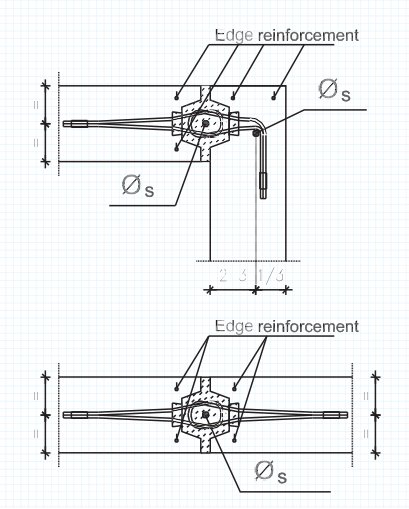

Reinforcement of the joint of HULK Metal Wire Loop Box:

When using wire rope loops, a vertical ribbed steel bar must always be installed through the wire loops as shown here.

Box Type

Part No

Recommended thickness of rope loop seam (mm)

Standard

HM-A

12

HM-B

12

HM-C

12

HM-D

12

HM-E

16

Case 1 – Where wire loops are used to transfer forces.

When HM wire rope loops are used to transfer forces in the joint, the anchorage of the wire rope loop must be secured by overlapping the wire rope loop sufficiently with the reinforcement of the concrete element. This should be done according to the engineer’s design depending on your precise arrangement.

Where the wire loop is used in a corner joint a reinforcing bar should be installed into the inner edge of the fold of the RVL wire rope loop, the diameter of this bar should be the same as the reinforcement installed in the joint.

Case 2 – Where HM wire loops are not used to transfer forces.

When wire rope loops are used to limit cracking of the seam or to tie elements together without defining the required force, additional reinforcement in the wall is recommended as shown here, including 2 No 10mm diameter additional bars in each piece.

Attachment to the formwork:

The wire rope loop box must be attached securely so it cannot move during the casting of the concrete. At the wire rope loop, the concrete must be compacted carefully as the loop cannot be vibrated. The wire rope loop boxes may be fastened to formwork with nails or by magnets.

The part of the wire rope that enters the concrete element is installed amidst the reinforcement and does not need to be tied to the reinforcement.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Lifting Anchors You Might Want to Know

Besides wire loop boxes, we also provide Lifting Clutch, Spread Anchors, Spherical Head Lifting Anchors, Lifting Sockets, and Recess Formers. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Wire Loop Box in Blogs

Here is the introduction, production, and quality inspection of the wire loop box that we can organize, as well as some sharing from customers and details of our delivery. You can message us to share or get some content about wire loop boxes.

Reviews

-

Diego Nanini

Earnest is very responsive. The product delivered on time and received in good condition.