How to Choose the Right Shuttering Magnets

In the construction industry, shuttering magnets have become one of the key tools to improve construction efficiency and safety. They are widely used in the production of precast concrete to firmly fix the formwork and ensure accuracy and stability during the concrete pouring process. This article will take a deep dive into how to choose the right shuttering magnets to help you make an informed decision when choosing, and provide some key points when choosing an OEM factory to ensure that you get a quality product.

Basic Definition and Working Principle of Shuttering Magnets

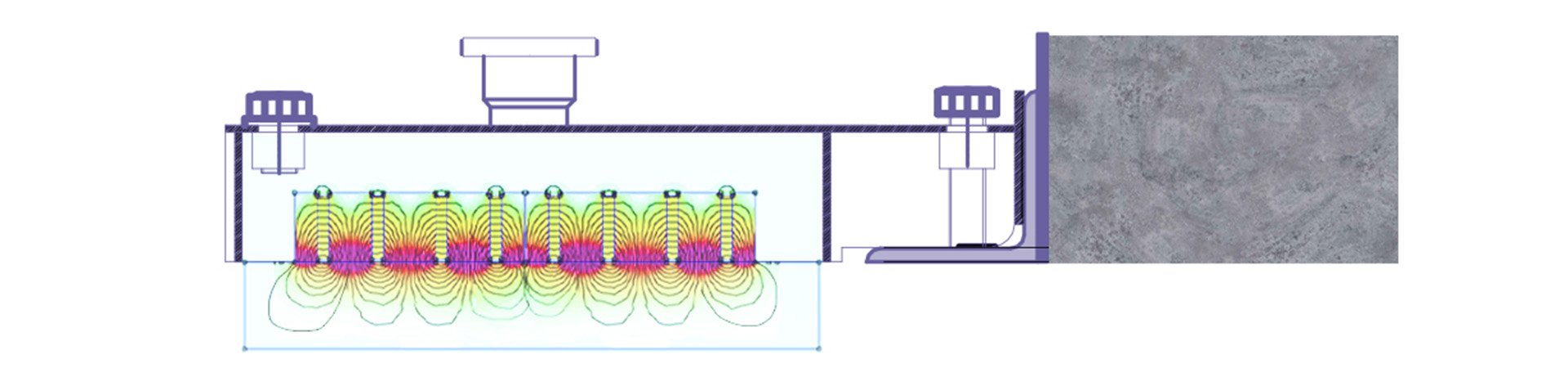

Shuttering Magnets is a tool that fixes the formwork through magnetic force. It uses a strong magnetic field to firmly attach the formwork to a specific position to ensure that the formwork does not move or deform during concrete pouring. Compared with traditional fixing methods such as bolts or clamps, shuttering magnets have more advantages because they are fast, easy, and can greatly improve construction efficiency.

Working Principle

The core working principle of Shuttering Magnets is to use strong magnetic force to firmly attach the metal formwork. When the formwork is in place, the operator activates the Shuttering Magnets, which emit a strong magnetic force to connect the formwork and the mold plate together. This magnetic force can be adjusted as needed to ensure that the formwork does not shift during the pouring process.

Common Types

Adjustable Magnetic Shuttering Magnets: Suitable for situations where the magnetic strength needs to be adjusted to accommodate formworks of different thicknesses.

Fixed Magnetic Shuttering Magnets: These magnets provide constant magnetic force and are suitable for standard formworks.

Auto-locking Shuttering Magnets: Provides higher safety and is suitable for high-risk projects.

Application Areas of Shuttering Magnets

Shuttering Magnets are widely used in the precast concrete production process, especially in the formwork installation stage of construction projects. The following are their main application areas:

Residential Construction: Used to quickly and accurately complete the formwork fixing work of precast concrete.

Commercial Construction: In large commercial construction projects, Shuttering Magnets can reduce manual labor and lower costs.

Infrastructure Construction: In complex structures such as bridges and tunnels, the use of Shuttering Magnets improves construction efficiency and reduces risks during construction.

Key factors when choosing the right Shuttering Magnets

When choosing the right Shuttering Magnets, you need to make decisions based on the following key factors:

Magnetic Strength

The strength of the magnetic force determines whether the Shuttering Magnets can firmly fix the formwork. Different construction projects will use formworks of different thicknesses and materials, so it is crucial to choose Shuttering Magnets with appropriate magnetic force. Too strong a magnetic force may make the formwork difficult to remove, while too weak magnetic force may cause the formwork to loosen, affecting the quality of the concrete.

Durability and Material

The material of the Shuttering Magnets directly affects its durability. High-quality shuttering magnets are usually made of high-strength steel or aluminum alloy, which can withstand long-term use and high-intensity working environments. Specially treated metal surfaces, such as galvanizing or coating, can effectively prevent corrosion and extend service life.

Design and convenience

Modern shuttering magnets are designed with user convenience in mind and are usually equipped with easy-to-operate magnetic force adjustment functions and convenient removal mechanisms. Choosing shuttering magnets with adjustable magnetic force allows you to use them flexibly in different construction environments.

Environmental adaptability

Shuttering magnets need to adapt to different construction environments, including high temperatures, humidity, and bad weather. Therefore, it is crucial to choose products with strong adaptability, especially for construction projects working in extreme environments.

Safety

Safety during the formwork fixing process is also a factor that needs to be focused on when choosing shuttering magnets. Some high-end models are equipped with a locking mechanism to prevent sudden failure of the magnetic force during construction.

Comparison of Shuttering Magnets with Other Formwork Fixing Methods

In the past, the commonly used formwork fixing methods on construction sites included bolts, clamps, and adhesives. In comparison, Shuttering Magnets have many advantages:

Time-saving: Using Shuttering Magnets can greatly shorten the time for formwork installation and removal, saving a lot of manpower and time compared to traditional methods.

Reduce labor intensity: Shuttering Magnets do not require additional tools, and construction workers can easily complete the formwork fixing work.

Improve construction accuracy: Because the formwork is more firmly fixed, the poured concrete is more accurate, thereby improving the quality of the project.

However, in some special cases, traditional fixing methods are still irreplaceable. For example, in situations where the formwork needs to be fixed for a long time, traditional bolt fixing may be more stable.

Common questions and answers when choosing Shuttering Magnets

1. How to evaluate the performance of Shuttering Magnets?

Choose quality-certified Shuttering Magnets by testing their magnetic force, durability, and ease of operation.

2. Are there universal shuttering magnet models?

Although there are some universal models on the market, customized shuttering magnets may be more suitable according to the needs of different projects.

3. What to do if the magnetic force is insufficient?

You can choose a model with stronger magnetic force, or add multiple shuttering magnets to meet the template fixing requirements.

Key points for selecting an OEM factory

When choosing an OEM factory for shuttering magnets, the following points are particularly important:

Quality control: Make sure the factory has ISO certification and professional testing equipment to ensure that the quality of each shuttering magnet meets industry standards.

Production process: Understand the factory's production capacity and technical level to ensure that it can handle large-scale production and high-precision requirements.

Customized service: Customized shuttering magnet solutions can be provided according to the special needs of the project.

Delivery and Service: Choose a factory that can provide fast delivery and has a complete after-sales service system to ensure that there will be no delays during the construction process.

Price and Cost: Reasonable price balances product quality and cost, and avoids choosing a supplier with too low a price that affects the overall quality of the project.

When choosing the right Shuttering Magnets, you must first understand the specific needs of the project, including the thickness of the formwork, the construction environment, and the budget. Secondly, it is crucial to choose an experienced OEM factory to ensure product quality and on-time delivery. As a professional Shuttering Magnets supplier, HULK Metal provides high-quality customized solutions that can meet the needs of various construction projects and is always committed to providing efficient and accurate services.

By gaining a deeper understanding of the selection points of shuttering magnets and the key factors of OEM factories, you can achieve a more efficient and safe construction process for your construction project.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.