Precast Concrete Magnets

Description:

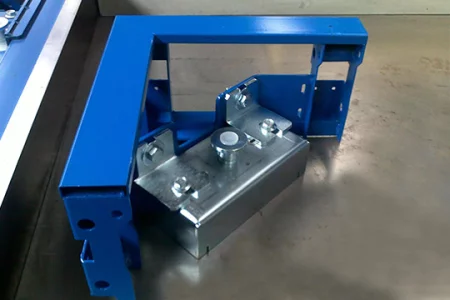

The magnetic box stands out as a specialized magnetic fixing device designed explicitly for securing precast concrete formwork.

In contrast to conventional mechanical fixing techniques like screws and nuts,

this innovative magnetic box fixation method eliminates the need for drilling or welding.

You Will Enjoy Them When You Buy Precast Magnets from HULK Metal.

Higher Quality Precast Magnets:

We own a factory equipped with advanced production equipment and testing equipment.

We also have an experienced quality inspection team to ensure your orders’ Qualification rate.

Shorter Production Cycle:

We will Design a better production solution for you according to your requirements.

Our production team can complete your orders faster.

Best Freight Solution:

We integrated hundreds of freight companies to provide you with suitable freight routes.

We also provide goods transit, goods warehousing, and other freight services.

Comprehensive After Service:

We have a professional after-service team to solve problems with technology, freight, quality, and others.

Dimensions and Tolerances of HULK Metal Precast Magnets

| NAME | HULK Metal Precast Magnets | |||

| Item No. | Adhesive Force | Item Size | Net Weight | |

| HM-SMB-600 | 600KG | 17*6*4cm | 1.8KG | |

| HM-SMB-800 | 800KG | 19*9*4cm | 3.0KG | |

| HM-SMB-900 | 900KG | 19*9*4cm | 3.2KG | |

Features of HULK Metal Precast Magnets:

-

Design Principles of HULK Metal Precast Magnets:

A magnetic fixing device specially developed for fixing precast concrete formwork.

Compared with the traditional bolt fixing method, the magnetic box has the characteristics of quick disassembly and assembly,

flexible operation, and strong fixing force, which effectively improves labor efficiency and reduces the loss of the formwork. , is now widely used at home and abroad.

The magnetic box is made of high-performance rare earth permanent magnet materials, which generates strong magnetic attraction in the magnetic circuit.

When the magnetic box is in working condition, the holding surface at the bottom of the magnetic block is tightly attached to the steel mold platform and held firmly.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

The Composition Of HULK Metal Precast Magnets:

The template fixing magnetic box is commonly used for most molds such as steel molds, aluminum molds,

and wood-based panel wooden side molds, and is placed on the steel formwork table to produce various precast concrete components.

It is mainly composed of three parts: a built-in heat-resistant permanent magnetic core, an external swing rod for docking,

and a stainless steel casing for maintenance. The fixed magnetic box uses the adsorption of the strong magnetic core and the steel mold table,

and transmits it to the stainless steel casing through the pendulum. It is positioned horizontally with the interface,

and high-hardness adjustable fastening screws are used to generate strong downward pressure, directly or through other fasteners.

The parts transmit pressure while firmly fixing the mold on the mold table. Using the adsorption between the NdFeB strong magnetic core and the steel mold table,

it is transmitted to the stainless steel button switch through the connecting screw rod to carry out the opening and closing operation of the magnetic box.

The single-sided or double-sided interface design can directly clamp the L-shaped angle iron side mold.

The 8.8-grade high-toughness adjustable fastening screws used on both sides can directly press down to fix the steel side mold,

thereby reinforcing the magnetic box and the The connection between angle irons effectively prevents the mold from shifting.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Installation of HULK Metal Precast Magnets:

1. When the magnetic box is in operation, foreign objects at the lower end should be prevented to reflect the adhesion between the magnetic box and the mold table.

This unit's magnetic box selects performance mode magnetic shielding material materials and customization, which brings a strong magnetic force chain in the magnetic circuit.

When the magnetic box is in operation, the holding surface at the lower end of the powerful magnet is firmly pressed against the steel mold platform body and held firmly.

(2) J—Beamless floor, represented by Southern European technology, has been widely used in civil buildings, but the seismic safety performance management can be improved.

However, when there are impurities (such as cement mortar, oil ester, polyester film) at the lower end of the powerful magnet that cannot be firmly pressed against the platform, the holding force will be greatly reduced.

2. Personal suggestions for cleaning: Before running the magnetic box, you should regularly check whether the lower end of the powerful magnet and the platform are clean and smooth.

If there are impurities at the bottom of the magnetic box, you can use a stainless steel knife to clean it (the plastic knife will be adsorbed by the resin and cannot be cleaned).

If there are materials that are difficult to clean such as cement mortar, you can use a polisher to clean it. As shown in the picture below, install the steel wire polishing disc on

the polishing machine and polish the lower end of the powerful magnet.

3. Hold it gently to prevent damage to the powerful magnet inside the magnetic box.

This is because the carbon-carbon composite material selected for the performance model of the powerful magnet is sintered from rare materials.

Its quality is similar to that of ceramics, hard and brittle, and easy to break. . Therefore, during the operation of the magnetic box,

it should be prevented from falling or smashing randomly, and it should not be separated by three pieces when removing the mold.

Avoid choosing hole-shaped shells (such as large plastic strings) that may cause damage or damage to the magnetic box and cause distortion of the magnetic box.

4. Collecting and sorting the magnetic boxes.

Personal suggestions, After the magnetic boxes have been run, handle the magnetic boxes for cleaning,

and place them on the stainless steel cart in a unified manner. Keep the magnetic boxes well cleaned to facilitate the first operation.

The magnetic box must not be placed on a plastic cart to prevent it from being stuck and unable to be removed.

5. Storage of magnetic boxes.

It is recommended that the surrounding environment for the operation and storage of magnetic boxes should not exceed 100°C,

and there should be no caustic soda solution, inorganic acid and other acidic materials nearby.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Maintenance of HULK Metal Precast Magnets:

(1) The platform for using the magnetic box should be kept clean and flat to prevent iron pins or concrete slurry from entering the inside of the magnetic box,

which will affect the flexibility of the switch. At the same time, it may cause the magnetic block to tilt and cannot be leveled for service. platform.

(2) The suction surface of the magnetic box should be kept clean and leveled continuously. If it is not needed for a long time, the suction surface should be oiled and treated to prevent rust.

You should always check whether the magnet can fit flatly into the platform and whether the switch is flexible and easy.

(3) During the use of the magnetic box, avoid hitting or scratching it with iron tools, which may cause the iron can to deform or even damage the magnet,

so as not to affect the performance indicators. If you must use special tools, it is recommended to use a vulcanized rubber hammer to tap gently.

(4) The magnetic force on the holding surface of the magnetic box is very strong. You should avoid getting close to instruments,

machinery and electronics and other components that are susceptible to magnetic damage. At the same time, do not get close to other iron materials.

Once they are attracted, they cannot be separated. . It is recommended to make special auxiliary tools to place the magnetic box and other magnetic fixing splints.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

OtherLifting Anchors You Might Want to Know

Besides wire precast magnets, we also provide Lifting Clutch, Spread Anchors, Spherical Head Lifting Anchors, Lifting Sockets, and Recess Formers. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Precast Magnets in Blogs

Here is the introduction, production, and quality inspection of the precast magnet that we can organize, as well as some sharing from customers and details of our delivery. You can message us to share or get some content about precast magnets.

-

January 31, 2024Precast Concrete Factory Tells You Why Choose Electric Box Fixing Magnets?

January 31, 2024Precast Concrete Factory Tells You Why Choose Electric Box Fixing Magnets?The electric box fixing magnets emerges as a transformative solution, offering many advantages such as stability, flexibility, ease of use and cost savings.

-

November 16, 2023Precast Magnets: Revolutionizing Formwork Fixation

November 16, 2023Precast Magnets: Revolutionizing Formwork FixationThe magnetic box stands out as a specialized magnetic fixing device designed explicitly for securing precast concrete formwork.

-

November 09, 2023Shuttering Magnets: The Pinnacle of Precast Concrete Formwork Solutions

November 09, 2023Shuttering Magnets: The Pinnacle of Precast Concrete Formwork SolutionsShuttering magnets represent a remarkable innovation in the realm of precast concrete construction.

Reviews

-

Diego Nanini

Earnest is very responsive. The product delivered on time and received in good condition.