Precast Magnetic Systems: Revolutionizing the Precast Concrete Industry

The precast concrete industry plays a crucial role in the construction of modern infrastructure. From skyscrapers to bridges, precast concrete is integral to building safe and durable structures. However, in such a highly competitive sector, manufacturers are always looking for ways to increase production efficiency, improve safety, and enhance product quality. This is where precast magnetic systems come into play.

Precast magnetic systems, particularly in the form of magnetic formwork, lifting systems, and inserts, have become a game-changer for precast concrete producers. These systems use magnetic forces to improve handling, positioning, and overall operational effectiveness. By offering flexible, reliable, and precise solutions, magnetic systems are revolutionizing how concrete components are fabricated, transported, and installed.

What Are Precast Magnetic Systems?

Precast magnetic systems are innovative devices used to assist in the manufacturing, handling, and transportation of precast concrete products. These systems rely on the use of powerful magnets to provide control and precision during various stages of production.

Definition and Functionality

At their core, precast magnetic systems consist of magnetic formwork, magnetic inserts, and magnetic lifting devices. These systems leverage magnetic fields to hold and position concrete elements, making the production process faster, more accurate, and more flexible. The primary role of these systems is to facilitate the easy handling of concrete molds, eliminate the need for mechanical fasteners, and improve safety during the lifting and transportation of precast elements.

Types of Magnetic Systems

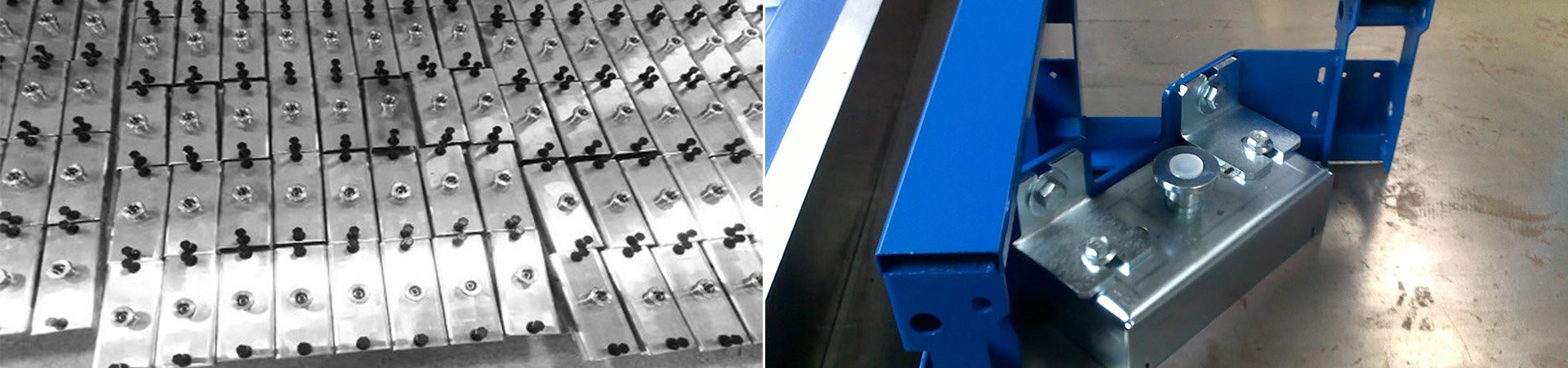

· Magnetic Formwork: These systems are used to hold the shape of the mold while the concrete is poured. They provide a non-invasive method to secure the formwork, making them reusable and reducing the risk of contamination.

· Magnetic Inserts: Insert magnets are placed within molds to provide secure anchorage points for lifting hooks, chains, or other lifting mechanisms. These inserts improve the speed and efficiency of the handling and lifting processes.

· Magnetic Lifting Devices: These are used to lift large precast elements with precision and ease. The use of magnets to lift heavy components significantly reduces labor costs and improves safety by eliminating the need for manual handling.

Advantages Of Traditional Systems

Compared to traditional methods, magnetic systems offer several significant advantages:

· Faster Setup and Teardown: Magnetic systems allow for quick repositioning, reducing downtime and increasing throughput.

· Higher Precision: Magnets provide more precise control over positioning, ensuring better quality and fewer errors.

· Reusable Components: Magnetic systems are durable and can be used multiple times, reducing material waste and overall costs.

Key Features and Benefits of Precast Magnetic Systems

Precision and Control

One of the standout features of magnetic systems is the precise control they offer during the production process. Magnets can be adjusted easily, allowing manufacturers to fine-tune the positioning of concrete elements to exact specifications. This level of precision ensures that the final product meets the necessary tolerances and quality standards.

Time-Saving

Time is money in the construction industry, and precast manufacturers know that reducing production time is essential for maintaining profitability. Magnetic systems significantly cut down on setup times by eliminating the need for manual labor to secure formwork or positioning tools. The result is a faster production cycle and better overall efficiency.

Durability and Reliability

Precast magnetic systems are designed for long-term use. Made from high-quality materials like neodymium magnets and durable steel casings, these systems are built to withstand the harsh conditions of a precast concrete environment. They offer high resistance to wear, corrosion, and mechanical stress, ensuring long-lasting reliability.

Enhanced Safety

The use of magnets in precast concrete production not only improves efficiency but also enhances safety. Traditional handling methods often involve manual labor or heavy lifting of equipment, which can result in workplace accidents. By utilizing magnetic systems, the need for human intervention in lifting and positioning is minimized, reducing the risk of injury.

Applications in the Precast Concrete Industry

Precast magnetic systems are versatile and can be used in various applications across the precast concrete industry. These systems improve the handling, lifting, and positioning of precast components, making them an indispensable tool in modern manufacturing processes.

Precast Wall Panels

Magnetic systems are ideal for securing large, heavy precast wall panels. By using magnetic lifting devices, these panels can be easily moved and positioned on-site, reducing the time needed for installation and ensuring accurate placement.

Concrete Slabs

Magnetic inserts can be used within slab molds to provide anchorage points for lifting. This ensures that the slabs are safely and precisely lifted without the need for additional fastening or positioning methods.

Beams and Columns

For larger precast components like beams and columns, magnetic formwork offers a reliable and cost-effective solution. Magnets can be used to hold the formwork in place, allowing for quick removal once the concrete has been set, speeding up the production process.

Custom Precast Components

In addition to standard precast products, magnetic systems can also be used in the production of custom precast components. These systems offer the flexibility to create molds and forms with varying shapes and sizes, enhancing the customization possibilities for manufacturers.

How Precast Magnetic Systems Improve Manufacturing Efficiency

Reduced Labor Costs

By reducing the need for manual handling, magnetic systems lower labor costs. Workers no longer have to spend time manually positioning molds or securing components, allowing them to focus on other tasks. This results in a more efficient workforce and reduced labor expenses.

Increased Throughput

Faster setup, positioning, and lifting times contribute to a higher production rate. Precast manufacturers can produce more elements in less time, maximizing the use of factory space and equipment. The increased throughput allows manufacturers to take on more projects and meet growing demand.

Quality Control and Consistency

With magnetic systems, there is less room for human error in the production process. The precision provided by magnets ensures that each component is manufactured to the same high standard. This leads to consistent quality across all products, minimizing defects and waste.

Case Studies and Real-world Applications

Case Study 1: Large-Scale Precast Concrete Manufacturer

A large precast concrete manufacturer in Europe implemented magnetic formwork and lifting systems across their production line. By integrating these systems, the company reduced setup times by 40% and improved overall production efficiency. The precision of the magnetic systems also reduced errors by 25%, leading to a significant decrease in rework and wastage.

Case Study 2: Smaller Projects with Limited Space

A small-scale precast manufacturer in Asia utilized magnetic inserts for their custom molds. The flexibility of the magnetic systems allowed them to quickly adapt to changing production needs, and they were able to reduce their labor costs by 30% while improving safety and reducing injuries.

Lessons Learned

From these case studies, it's clear that the use of magnetic systems can lead to significant improvements in both large and small precast operations. The key takeaway is that magnetic systems provide scalable solutions that can be tailored to a variety of production environments.

Why Choose HULK Metal as Your Precast Magnetic System Supplier?

Expertise in Manufacturing

HULK Metal has years of experience in producing high-quality precast magnetic systems. With a deep understanding of the needs of the precast concrete industry, HULK Metal is able to provide tailored solutions that optimize production efficiency and safety.

Innovative Solutions

At HULK Metal, we continuously innovate our product offerings to keep pace with advances in technology. Our magnetic systems are designed with cutting-edge materials and processes, ensuring that they meet the highest standards of performance and durability.

Customized Solutions

Every precast concrete operation has unique requirements. HULK Metal offers customized magnetic systems to suit the specific needs of your production line. Whether you're working with large panels or small, intricate components, we have the right solution for you.

Commitment to Quality and Safety

We are committed to maintaining the highest quality standards for all our products. HULK Metal’s magnetic systems undergo rigorous testing to ensure they meet industry standards for reliability, strength, and safety.

Cost-Effective Solutions

We offer competitive pricing without compromising on quality. Our solutions are designed to help you achieve long-term savings by

Cost-Effective Solutions

We offer competitive pricing without compromising on quality. Our solutions are designed to help you achieve long-term savings by reducing downtime, improving efficiency, and minimizing labor costs. HULK Metal’s magnetic systems are durable, reusable, and built to withstand the toughest conditions, ensuring that your investment delivers excellent returns over time.

Global Reach and Reliable Logistics

As a trusted supplier in the precast concrete industry, HULK Metal has established a global presence with a reliable logistics network. We are committed to providing timely deliveries to customers worldwide, ensuring that your projects stay on schedule. Whether you are located in Europe, Asia, North America, or beyond, HULK Metal can support your needs with fast, secure, and efficient shipping.

Why Choose HULK Metal as Your Precast Magnetic System Supplier?

Choosing HULK Metal as your supplier for precast magnetic systems comes with a host of advantages that ensure your operations are optimized for success.

Expertise and Experience

With years of experience in manufacturing magnetic systems specifically for the precast concrete industry, HULK Metal understands the unique challenges that manufacturers face. Our expert team has developed solutions that address these challenges, providing products that are easy to use, reliable, and cost-effective.

Cutting-Edge Technology

We continually invest in research and development to ensure our magnetic systems are equipped with the latest technology. Whether it's advanced materials like neodymium magnets or the integration of automation and smart sensors, HULK Metal’s magnetic systems incorporate the most cutting-edge innovations available to enhance your production efficiency.

Customization to Fit Your Needs

No two precast manufacturers are the same. HULK Metal recognizes that each business has unique requirements. That’s why we offer tailored magnetic systems that meet the specific needs of your production line, ensuring that you get the most efficient and cost-effective solution for your operations.

Exceptional Customer Service

At HULK Metal, we prioritize customer satisfaction above all else. Our dedicated customer service team is always ready to assist with any inquiries, ensuring that you get the support you need, when you need it. From product selection and installation to after-sales support, we are here to help every step of the way.

Stringent Quality Control

We take quality seriously at HULK Metal. Every magnetic system we produce undergoes rigorous quality checks to ensure it meets the highest standards of safety, durability, and performance. Our systems are designed to last, provide long-term value, and reduce your overall operating costs.

Cost-Effective Pricing

We understand that cost efficiency is a critical factor in the success of any manufacturing operation. HULK Metal’s magnetic systems offer the perfect balance of quality and affordability. Our solutions deliver exceptional performance, helping you achieve faster production cycles, reduced labor costs, and higher product quality—all at a competitive price.

Global Distribution Network

With a global presence and an extensive distribution network, HULK Metal can supply your precast magnetic systems wherever you are. We offer fast, reliable shipping, ensuring your orders arrive on time and are ready for use. Whether you are located in North America, Europe, Asia, or the Middle East, we have the infrastructure to support your business needs.

Sustainability Commitment

Sustainability is at the core of HULK Metal's operations. Our magnetic systems are designed for long-term durability and reuse, reducing waste and promoting environmental responsibility. By choosing HULK Metal, you’re not only investing in high-performance systems but also contributing to a more sustainable future for the precast concrete industry.

precast magnetic systems represent a critical advancement in the precast concrete industry, providing increased efficiency, precision, safety, and cost-effectiveness. Whether you are producing precast wall panels, slabs, beams, or custom components, magnetic systems offer flexible and reliable solutions to improve your production processes.

By choosing HULK Metal as your supplier, you can leverage our years of expertise, cutting-edge technology, and commitment to quality to enhance your manufacturing capabilities. We offer customized magnetic systems tailored to your specific needs, backed by exceptional customer service and competitive pricing. With a global distribution network and a focus on sustainability, HULK Metal is the trusted partner for precast concrete manufacturers looking to improve their efficiency, reduce costs, and achieve better outcomes.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.