How to Use Precast Concrete Lifting Anchors: A Comprehensive Guide

As an indispensable tool in construction, precast concrete lifting anchors are widely used to lift, install, and position heavy concrete components. Proper use of precast concrete lifting anchors not only improves construction efficiency but also ensures safety and stability. This article will take a deep dive into how to use these lifting anchors safely and efficiently and provide a series of steps and practical suggestions to help construction teams ensure correct operation.

Planning and Design

Determine the weight and lifting requirements of concrete components

Before using precast concrete lifting anchors, the first step is to understand the weight and lifting requirements of concrete components. Engineers need to accurately calculate the size and weight of concrete components and determine the lifting plan based on the site environment. The calculation of weight is the basis for selecting the type of lifting anchor. Generally speaking, the heavier the component, the more powerful or more lifting anchors are required.

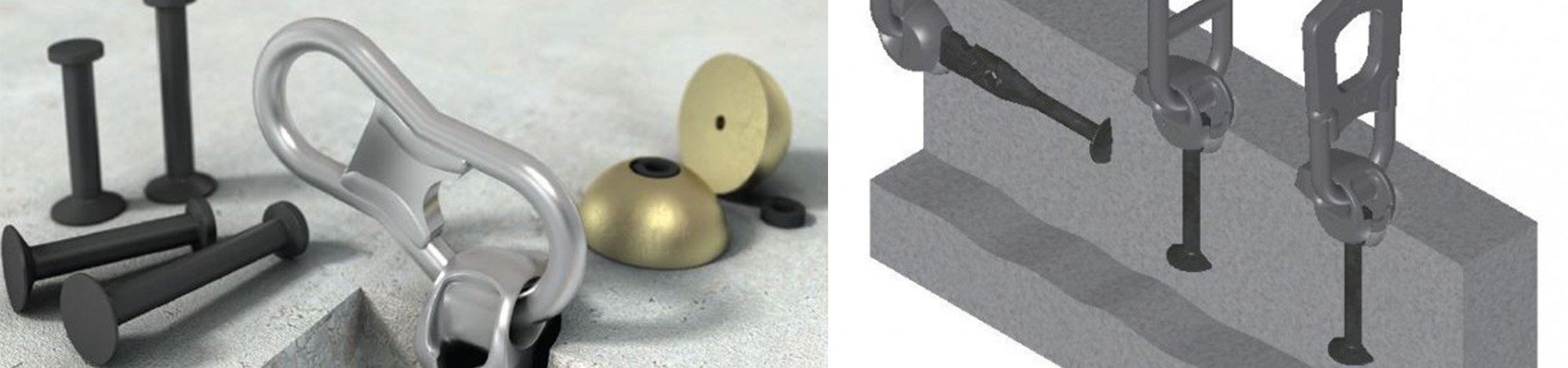

Choose the right type of lifting anchor

There are many types of lifting anchors, including Spherical double-heated lifting Anchors, lifting eye anchors, utility anchors, and all-around lifting anchors. Choosing the right type of lifting anchor directly affects the safety and stability of the construction process. When designing, the lifting anchor type should be reasonably selected according to the shape, size, and lifting method of the concrete component to ensure that the load can be evenly distributed during the lifting process.

The role of engineers: load calculation and design plan

The role of engineers in lifting operations is crucial. They need to develop detailed lifting plans based on factors such as the weight of the component, the lifting method, and the safety factor. The design plan should take into account the layout of the lifting anchor, the allocation of lifting points, and the selection of lifting equipment to ensure safety and efficiency during the construction process.

Anchor installation

Selection of anchor position and direction

The installation of the lifting anchor is carried out during the pouring of the concrete component. The precise position and direction of the anchor are crucial to ensure stability and balance during the lifting process. Engineers should accurately locate the anchor point according to the design requirements and ensure that the anchor is vertical or parallel to the surface of the component to avoid unstable lifting due to improper angles.

Anchor installation process

The lifting anchor is usually embedded in the component during the concrete pouring process. During operation, the lifting anchor needs to be placed strictly in accordance with the design drawings and construction specifications. During installation, the anchor should be firmly embedded in the concrete to avoid looseness or instability. All anchored steel bars and connecting parts need to be quality-checked to ensure that they will not move during the concrete hardening process.

Ensure the firmness of the anchor

The firmness of the anchor is directly related to the safety of the lifting process. During installation, the alignment of the anchors needs to be checked to ensure that they are not moved by external forces. In addition, high-quality embedded parts should be used to avoid hidden dangers caused by poor materials. The installation of anchors is not only a technical job but also a test of the construction workers' sense of responsibility.

Concrete curing

Importance of the curing process

Concrete curing is a key link to ensure that the lifting anchor can fully play its role. After the concrete is poured, it needs to be cured for a certain period of time to reach the design strength. During the curing process, the position of the lifting anchor must remain stable to avoid position displacement caused by external factors such as vibration or mechanical interference.

Precautions during curing

During the curing process, it is necessary to ensure that the concrete surface is always properly moist to promote the hydration reaction. The lifting anchor part must be protected from damage and the anchor position should always be kept in the correct position. Avoid applying external forces to the concrete components during the curing process, which may affect the final strength and anchoring effect of the concrete.

Lifting operation

Selection and inspection of lifting equipment

Once the concrete is cured, the lifting operation can begin. Lifting equipment, such as cranes and hoists, must be carefully inspected to ensure that they are working properly. The selection of cranes should be determined based on the weight of the lifting load to ensure that its lifting capacity can meet the construction requirements.

Connecting the lifting clutch to the lifting anchor

Before the lifting operation begins, the operator should firmly connect the lifting clutch to the lifting anchor. The clutch selection should meet the specifications of the lifting anchor to ensure that the connection is stable and not loose. After the connection is completed, it is also necessary to check whether the sling and hook are within the working load range.

Precautions during lifting

During the lifting process, the operation should be carried out slowly to avoid the sudden application of excessive loads. The lifting operation should ensure that the load is evenly distributed between multiple lifting anchors. Operators should be vigilant and observe the lifting process to prevent any accidents that may cause load imbalance or loosening of the lifting anchor.

Positioning and installation

Accurate positioning of concrete components

The lifted concrete components should be accurately positioned as required by the design. This process requires a high degree of collaboration and fine operation. The crane operator and the ground commander must work closely together to ensure that the components are placed in the correct position.

Operational skills for accurate installation

During the installation process, the concrete components may have slight deviations, so careful adjustment methods are required to ensure that they are accurately positioned. Fine adjustment devices or hydraulic devices can be used to make adjustments to ensure the accuracy of the component position.

Safety inspection and the role of lifting anchor

After installation, the concrete components need to be inspected to ensure that the lifting anchor is not damaged and is secure. The lifting anchor ensures the stability of the concrete components during transportation and installation, which is a key safety guarantee during the construction process.

Inspection and verification

Inspection after completion

Once the concrete components are correctly installed, the construction team needs to conduct a comprehensive inspection. Inspection items include whether the installation of the lifting anchor meets the design requirements, whether the lifting anchor is damaged, and the fixing of the concrete component.

Ensure long-term stability and safety

The stability of concrete components is not only reflected during installation but also involves the bearing capacity in long-term use. Therefore, it is crucial to ensure that the lifting anchor is not damaged and the concrete component is firmly bonded to the lifting anchor. When conducting on-site quality inspections, special attention should be paid to potential problems such as cracks on the concrete surface and loose anchors.

How to use precast concrete lifting anchor

The use of a precast concrete lifting anchor requires the following steps:

1. Planning stage: Determine the weight of the concrete component, lifting method, and type of lifting anchor.

2. Anchor installation: Install the lifting anchor according to the design requirements and ensure it is firm.

3. Curing period: Concrete needs to be properly cured to ensure strength and anchor stability.

4. Lifting operation: Connect the lifting equipment to ensure that the load is evenly distributed.

5. Installation positioning: Accurately install the concrete component and conduct a quality inspection to ensure long-term stability.

By following these steps, the construction team can maximize the safety and efficiency of the lifting operation and ensure the smooth installation of the concrete components.

Through reasonable planning, precise installation, and meticulous lifting operations, the precast concrete lifting anchor can effectively ensure the safe lifting and positioning of concrete components. The construction team needs to strictly follow the standard operation at each stage to ensure safety and efficiency during the construction process. The proper use of precast concrete lifting anchor is an important factor in ensuring the smooth progress of the construction project.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.