Application and development of Insert Magnet in precast concrete

As a key component in precast concrete production, insert magnets have become an important tool in modern construction. It uses strong magnetic adsorption force to accurately fix the position of embedded parts on the formwork, thereby ensuring the dimensional accuracy and quality of concrete components. This article will deeply explore the structure and working principle, advantages, application fields, selection points, maintenance, and future development trends of insert magnets, and comprehensively analyze its important role in the precast concrete industry.

Structure and working principle of insert magnets

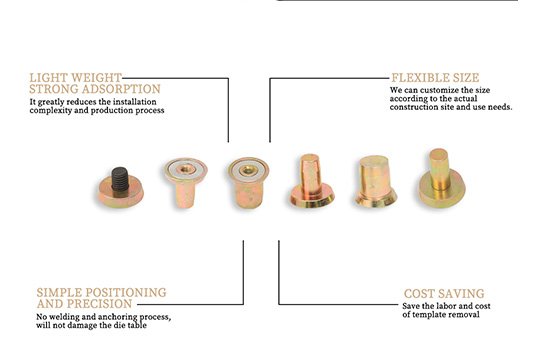

The design of insert magnets is both scientific and practical, and its core consists of the following parts:

High-performance magnetic core: Insert magnets usually use high-performance rare earth permanent magnet materials such as neodymium iron boron (NdFeB), which have excellent magnetism and long-term stable adsorption capacity. The performance of the magnetic core directly affects the use effect of the magnet, so it is the key to its design.

Sturdy shell protective layer: The shell is made of high-quality steel or stainless steel, with good impact resistance and corrosion resistance. The surface is usually electroplated to enhance its antioxidant ability so that it can maintain excellent performance in a construction environment with high humidity.

Internal optimization design: The internal structure is exquisitely designed to effectively disperse the magnetic force and enhance the fixing strength. Some insert magnets also have built-in shock-absorbing structures to reduce the impact during installation.

Its working principle is to firmly fix the embedded parts on the surface of the steel formwork through the strong adsorption force of the magnetic core. During the concrete pouring process, the adsorption force of the magnet ensures that the embedded parts will not shift, thereby achieving high precision and high consistency in the production of components.

Advantages of insert magnets

The reason why insert magnets can be widely used in the precast concrete industry is inseparable from their significant advantages:

Efficiency: Compared with traditional drilling or welding fixing methods, insert magnets can greatly reduce the time of installation and disassembly, improve construction efficiency, and save manpower and resources.

Flexibility: The position of the magnet can be adjusted at any time according to actual needs, which makes the production of precast components more flexible and adaptable to complex design requirements.

Reusability: After reasonable design and manufacturing, the insert magnet has a long service life and can be reused many times, which greatly reduces the construction cost.

Protection of the formwork: There is no need to drill or weld the formwork, which extends the service life of the steel formwork and reduces maintenance costs.

Environmental protection: Insert magnets do not produce pollutants during use, which is more in line with the development direction of modern green buildings.

Application areas of insert magnets

The application of insert magnets runs through many links of precast concrete components, and its main uses include:

Fixing threaded sleeves: In precast concrete wall panels or beams, threaded sleeves are often used as embedded parts for component connection or lifting. Insert magnets can accurately fix threaded sleeves to ensure their accurate position.

Positioning of lifting anchors: Lifting anchors are important components in the transportation and installation of precast components. The use of insert magnets ensures the firmness and precision of lifting anchors in components.

Fixing of pipes and cable sleeves: In construction, it is a common requirement to reserve pipe and cable channels. Insert magnets can effectively fix these sleeves to avoid displacement or deformation during concrete pouring.

Installation of customized embedded parts: For specially designed precast components, insert magnets can be customized according to needs to meet complex and changing construction requirements.

Key points for choosing insert magnets

Faced with the diverse insert magnet products on the market, it is crucial to choose the right product. The following points are the core elements to pay attention to when choosing:

Magnetic force: According to the size and weight of the embedded parts, choose an insert magnet with sufficient magnetic force. Insufficient magnetic force may cause the embedded parts to shift during construction, while excessive magnetic force may increase the difficulty of operation.

Shell quality: The material and process of the shell are directly related to the durability and corrosion resistance of the magnet. A high-quality shell can significantly extend the service life of the magnet.

Adaptability: The shape and size of the insert magnet should match the embedded parts and template to ensure the firmness and convenience of installation.

Cost-effectiveness: Consider the unit price, service life and performance of the product comprehensively, and choose the product with the highest cost-effectiveness.

Manufacturer: Choose a manufacturer with rich experience and a good reputation to ensure product quality and after-sales service.

Maintenance and maintenance of insert magnets

The life and performance of insert magnets depend largely on daily maintenance and maintenance. Here are some key maintenance suggestions:

Keep it clean: Make sure there is no dirt, concrete residue and other debris on the surface of the magnet to avoid affecting its adsorption.

Anti-corrosion treatment: In humid or corrosive environments, anti-corrosion measures should be taken, such as regular application of anti-rust oil or the use of more corrosion-resistant shell materials.

Proper storage: When not in use, store the magnet in a dry environment and avoid contact with other strong magnetic objects.

Regular inspection: Regularly check the magnet's magnetism, shell integrity, and adsorption force, and replace defective products in time.

Future development trends of insert magnets

With the continuous advancement of construction technology, insert magnets are also constantly upgrading to meet the needs of more efficient and smarter construction. Future development trends include:

Improvement of magnetic materials: Develop higher-performance rare earth permanent magnet materials to provide stronger magnetic force while reducing the weight and volume of magnets.

Intelligent design: By embedding sensors and wireless modules, the position of embedded parts can be monitored and adjusted remotely in real-time.

Modular products: Provide magnet modules of various specifications and shapes, and users can flexibly combine them according to their needs.

Green and environmentally friendly materials: With the popularization of green buildings, the manufacture of magnets will use more recyclable and low-carbon materials to reduce the impact on the environment.

Automated supporting equipment: Develop automated installation equipment that matches the insert magnets to further improve construction efficiency.

Insert magnets have become an indispensable tool in precast concrete production due to their high efficiency, flexibility and environmental protection. By deeply understanding their structural principles, selection points and future development trends, construction companies can better utilize the advantages of insert magnets to improve project quality and construction efficiency. With the continuous advancement of technology, insert magnets will play a more important role in the construction industry and provide strong support for the development of green and intelligent buildings.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.How to Choose High-Quality Shuttering Magnetic Products and Suppliers Guide

- 2.Applications and advantages of swivel hoist rings: HULK Metal provides you with safer and more flexible lifting solutions

- 3.Precast Concrete Factory Tells You Why Choose Electric Box Fixing Magnets?

- 4.Precast Magnets: Revolutionizing Formwork Fixation

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.