Lifting Sockets vs Lifting Anchors: Which Is Better for Precast Concrete?

Precast concrete has become one of the key materials in modern construction. Whether you are working on large infrastructure projects or building residential developments, using precast concrete components can significantly improve efficiency, consistency, and safety on-site. But handling and transporting these heavy concrete elements is a serious job that requires the right lifting system.

Among the lifting solutions available, two names often come up: Lifting Sockets and Lifting Anchors. Both are widely used in precast concrete construction, but which one should you choose for your project?

In this article, we’ll break down exactly what lifting sockets and lifting anchors are, their differences, their applications, and most importantly, how to decide which is better for your precast concrete needs.

What Are Lifting Sockets?

Lifting sockets are embedded steel components designed to provide secure lifting points within precast concrete products. They are usually used in conjunction with threaded lifting loops, lifting bolts, or lifting eyes during the lifting process. These sockets stay embedded in the concrete and are often hidden after installation, leaving a clean and professional appearance on the surface.

Common Types of Lifting Sockets

Threaded Sockets (Internal Thread) – Suitable for small to medium-sized concrete elements.

Wave Sockets – Known for better anchoring within the concrete.

Flat End Sockets – Often used where space is limited.

Nailing Plates or Fixing Accessories – Assist with positioning during concrete pouring.

Advantages of Lifting Sockets

Neat Appearance – After lifting, the socket remains flush or concealed, ideal for visible concrete surfaces.

Customizable – Available in various sizes, thread types, and load capacities.

Cost-Effective – Especially for lighter or decorative precast elements.

Flexible Installation – Easy to use with various lifting bolts or lifting loops.

What Are Lifting Anchors?

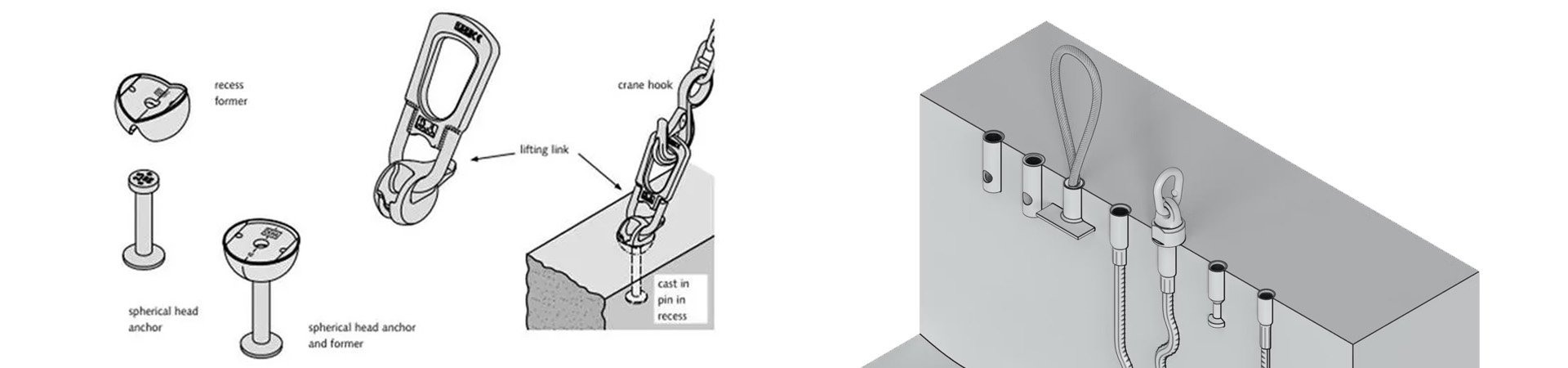

While lifting sockets provide an internal thread for lifting accessories, lifting anchors are specially designed steel inserts embedded into the concrete, creating robust lifting points for direct attachment with specialized lifting clutches. These systems are ideal for heavy or oversized precast elements such as beams, walls, or staircases.

Common Types of Lifting Anchors

Flat Plate Anchors – Often used in thin concrete elements.

Headed Anchors (Disc Anchors) – Known for high load capacities.

Recessed Anchors with Magnetic Recess Formers – Allow for easy removal of lifting clutches after lifting.

Advantages of Lifting Anchors

High Load Capacity – Perfect for lifting heavy precast concrete elements.

Fast Installation – Used with quick-connection lifting clutches.

Reliable Performance – Tested to meet high safety standards.

Versatile – Available in many designs to suit different lifting conditions.

Key Differences Between Lifting Sockets and Lifting Anchors

Choosing between lifting sockets and lifting anchors requires understanding their core differences:

Feature | Lifting Sockets | Lifting Anchors |

Appearance | Hidden or flush after installation | Usually requires additional surface treatment |

Load Capacity | Suitable for light to medium precast elements | Designed for heavy-duty lifting |

Lifting Accessories | Requires threaded lifting loops or bolts | Used with lifting clutches for quick connection |

Application | Decorative panels, smaller concrete elements | Beams, columns, and heavy wall panels |

Cost | Generally lower cost | Higher due to specialized design |

In short, lifting sockets are great for smaller, lighter elements where appearance matters. Lifting anchors are better when you need superior strength and faster, safer lifting operations.

How to Choose: Factors You Should Consider

So, how do you decide which lifting solution fits your project? Here are some practical points to guide your choice:

Weight and Size of Precast Elements

Use lifting sockets for lighter elements such as decorative panels, steps, or facade components.

Choose lifting anchors when dealing with large, heavy concrete structures like walls, beams, or bridge components.

Installation and Handling

If your team prefers using threaded lifting loops or bolts for adjustable lifting points, lifting sockets make sense.

For projects requiring fast lifting cycles or frequent lifting, lifting anchors with clutch systems offer speed and efficiency.

Aesthetic Requirements

For architectural precast concrete, lifting sockets provide a cleaner finish.

Lifting anchors may require surface treatment or patching after lifting.

Safety Standards

Heavy elements demand higher safety standards. Lifting anchors are usually rated for higher load capacities and have detailed testing certifications to back their performance.

Project Budget

Lifting sockets often provide a cost-effective solution for simpler jobs.

Although more expensive, lifting anchors offer long-term reliability and reduced lifting time on-site, saving labor costs in the long run.

When to Use Lifting Sockets vs. Lifting Anchors

To make things even clearer, let’s break down some common scenarios where one might be a better choice than the other:

Choose Lifting Sockets If:

You’re lifting small to medium-sized precast panels.

The visible finish of the concrete matters after installation.

You want lower upfront material costs.

Customization of the socket size or thread type is required.

Choose Lifting Anchors If:

Your project involves large, heavy concrete components.

You need fast and efficient lifting operations.

Safety standards are a top priority, especially in structural components.

The project includes repeated or high-load lifting operations.

Why Choose HULK Metal for Your Precast Lifting Solutions

At HULK Metal, we specialize in providing high-quality lifting sockets and lifting anchors tailored to meet the exact demands of your precast concrete projects. We don’t just supply products — we deliver complete solutions backed by engineering expertise.

Here’s why builders worldwide trust HULK Metal:

Wide Range of Products – From threaded lifting sockets to high-load lifting anchors, we have the right solution for every application.

Custom Manufacturing – Send us your drawings, and we’ll manufacture lifting systems that perfectly match your design needs.

Certified Quality – Every product undergoes strict tensile strength tests, magnetic particle inspections, and dimensional checks.

Global Shipping – Our experienced logistics team ensures safe, on-time delivery anywhere in the world.

Dedicated Support – From technical consultation to after-sales service, our professional team stands ready to assist your project at every stage.

Whether you’re working on small decorative elements or massive precast structures, we’ll make sure you have the right lifting system in place.

Both lifting sockets and lifting anchors play essential roles in precast concrete construction. They serve different needs depending on project size, load requirements, and visual expectations.

Lifting Sockets shine in smaller applications where appearance matters and loads are moderate. Lifting Anchors dominate when strength and speed take priority, especially with larger and heavier elements.

The right choice comes down to your specific project needs, and that’s where HULK Metal can help. With expert advice, superior quality, and global delivery, we’ll provide exactly what you need to complete your precast concrete lifting tasks safely, efficiently, and on budget.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.