What is the Load Limit on Lifting Anchor?

Lifting anchors are essential components in the precast concrete construction industry, designed to safely lift, transport, and position heavy concrete elements. As the structural integrity and safety of construction projects largely depend on the performance of lifting systems, understanding the load limit of lifting anchors is crucial. The question "What is the load limit on lifting anchor?" is not just a technical inquiry but a fundamental concern that affects site safety, project timelines, and overall structural reliability.

This article will explore what determines the load limit of a lifting anchor, how to calculate it, and why precise knowledge of this parameter is indispensable. Whether you're an engineer, a contractor, or a procurement officer, gaining clarity on this topic will enhance your lifting system's safety and efficiency.

What is a Lifting Anchor?

A lifting anchor is a specially designed steel insert embedded in precast concrete elements to facilitate lifting and transportation. These anchors come in various shapes and sizes, including foot anchors, spread anchors, ring anchors, and lifting sockets. Each type is engineered for specific load directions and applications, from vertical lifting to angled tension loads.

Lifting anchors are usually paired with a compatible lifting clutch or device that ensures secure connection during lifting. They are made from high-strength materials such as forged alloy steel, often heat-treated to withstand heavy loads without deforming or failing.

Their strategic placement and proper installation in concrete elements ensure that these components handle both static and dynamic forces effectively during lifting operations.

Understanding Load Limits: Why It Matters

The load limit of a lifting anchor refers to the maximum force it can safely withstand during lifting. This is often represented in two ways:

Working Load Limit (WLL): The maximum load a lifting anchor can sustain under normal operating conditions with a specified safety factor.

Breaking Load: The load at which the anchor will fail or break under extreme stress.

Understanding the load limit is essential for several reasons:

Safety: Exceeding the load limit can lead to catastrophic failures, endangering workers and damaging property.

Compliance: Construction codes and standards require adherence to specified load capacities.

Efficiency: Correctly rated lifting anchors prevent over-engineering and reduce costs while maintaining safety.

Ignoring load limits can result in cracked concrete, dropped elements, equipment damage, and even fatal accidents.

Factors that Affect Lifting Anchor Load Limits

Several key factors influence the load-bearing capacity of a lifting anchor:

Anchor Design and Geometry:

The physical shape of the anchor, such as whether it has a foot, spread plate, or spherical head, directly impacts its load distribution and ultimate strength.

Material Properties:

High-quality forged alloy steel offers better tensile strength and fatigue resistance than mild steel. Heat treatment further enhances durability and load performance.

Concrete Strength:

The compressive strength of the concrete (typically denoted as C25, C30, C40, etc.) significantly affects anchor performance. Higher-strength concrete offers greater resistance to pull-out and shear forces.

Embedment Depth:

The deeper the anchor is embedded into the concrete, the higher its resistance to pull-out. However, this must be balanced with design practicality.

Anchor Orientation and Load Angle:

Lifting at an angle reduces the effective load capacity due to shear and bending forces. Most load charts provide reduction factors for angled lifts.

Edge Distance and Spacing:

Anchors placed too close to the concrete edge or each other may reduce overall capacity due to concrete breakout risk.

For example, a foot anchor embedded in C35 concrete with proper spacing and vertical lifting orientation will have a significantly higher load capacity than the same anchor placed in C20 concrete or used at a 45-degree lifting angle.

How to Calculate the Load Limit of a Lifting Anchor

Calculating the load limit involves a combination of empirical data, engineering judgment, and reference to design standards. Standards such as EN 1992 (Eurocode 2), ACI 318, and local building codes provide frameworks for evaluating lifting systems.

Basic Calculation Steps:

Identify Anchor Type and Dimensions:

Refer to the manufacturer’s technical datasheets for specifications.

Check Concrete Strength:

Confirm the compressive strength of the concrete used in the element.

Determine Load Direction:

Identify if the lift is vertical or angled; apply relevant reduction factors for non-vertical lifts.

Calculate Design Load:

Use formulas provided in standards or manufacturer manuals. Include safety factors (typically 3 to 5, depending on the application).

Example:

For a 10 mm spread anchor in C30/37 concrete:

WLL (vertical): ~1.3 tons

WLL (angled 45 degrees): ~0.9 tons (after applying reduction factor)

Always verify calculations with the manufacturer’s published data.

Choosing the Right Anchor for Your Load Requirement

Selecting the right anchor is not solely about lifting capacity. It also involves matching the anchor to your project requirements:

Type of Concrete Element: Wall panel, slab, column, or beam.

Lifting Configuration: Vertical, tilt-up, or rotation.

Load Weight and Distribution: Uniform or point loads.

Tips for Selection:

Use the technical load charts provided by manufacturers.

Avoid generic anchors; use certified products from trusted suppliers.

Consider future handling needs—some anchors allow reuse.

A mismatch between the anchor type and the application can compromise safety and result in failure.

Safety Guidelines and Best Practices

Lifting anchors must be used in conjunction with stringent safety practices:

Regular Inspections:

Check for corrosion, deformation, or cracks in anchors and lifting clutches.

Match Clutch and Anchor:

Only use compatible, certified lifting clutches to ensure full engagement.

Controlled Lifting Angles:

Follow specified angle limits to prevent overload.

Training:

Ensure workers are trained in proper installation, lifting, and inspection procedures.

Use Safety Factors:

Always apply safety margins as prescribed by standards or the manufacturer.

Following these practices reduces the risk of on-site incidents and prolongs anchor's lifespan.

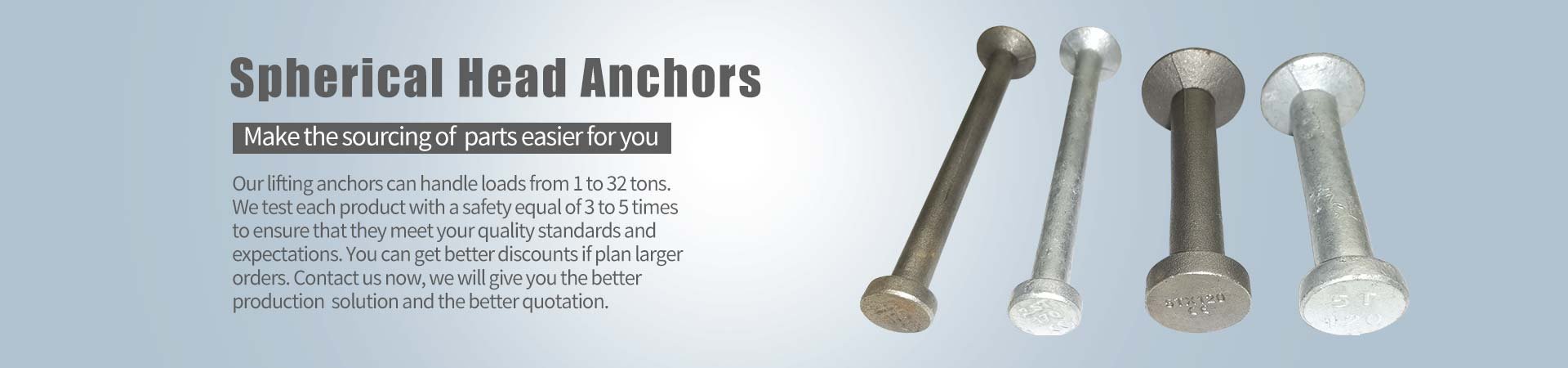

HULK Metal: Your Trusted Lifting Anchor Manufacturer

HULK Metal is a leading manufacturer of lifting anchors and precast lifting systems. We specialize in forging high-strength, precision-engineered anchors suitable for a wide range of precast concrete applications. Our lifting anchors are manufactured using heat-treated alloy steel and undergo rigorous testing to ensure consistent performance.

Why Choose HULK Metal:

Advanced Manufacturing: Precision forging, CNC machining, and surface treatment ensure optimal product integrity.

Quality Assurance: Our products meet CE, TUV, and SGS standards.

Technical Expertise: We offer load calculation support, technical datasheets, and customized solutions.

Global Supply Chain: Fast delivery and responsive support backed by an experienced logistics team.

Whether you need standard lifting anchors or custom-designed solutions, HULK Metal can meet your requirements with high efficiency, safety, and reliability.

Contact HULK Metal today to discover how our lifting anchors can enhance your next precast construction project.

Understanding the load limit on lifting anchors is critical for ensuring safe and efficient handling of precast concrete components. From choosing the right type to calculating its capacity and applying best safety practices, every step matters in preventing costly failures and safeguarding your workforce.

Partnering with a trusted manufacturer like HULK Metal ensures that your lifting anchors not only meet but exceed industry standards. Make informed decisions and build with confidence by integrating reliable lifting systems into your construction processes.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.