How Lifting Anchors, Lifting Clutches, and Recess Formers Work Together in Precast Lifting

Precast concrete construction is a rapidly growing solution in modern infrastructure due to its speed, quality, and efficiency. However, lifting and placing heavy concrete components require more than just raw power—it requires precision, safety, and well-matched accessories. Three essential elements form the backbone of an effective precast lifting system: Lifting Anchors, Lifting Clutches, and Recess Formers.

In this article, we’ll explore how these components work individually and how, when used together, they create a seamless and reliable lifting process. Whether you're an engineer, site supervisor, or construction manager, mastering this system is key to ensuring jobsite safety and efficiency.

What Are Lifting Anchors and How Do They Work?

A Lifting Anchor is a specially designed embedded part used to lift, handle, and install precast concrete elements safely. These anchors are strategically placed inside the concrete before it cures and serve as the connection point for lifting clutches or lifting devices.

Types of Lifting Anchors

T Anchors: Provide strong load transfer and are widely used in walls, columns, and beams.

Double Head Anchors: use for safely lifting heavy precast concrete elements, ensuring strong load-bearing capacity and stable vertical handling in construction and infrastructure projects.

Eye Anchors: Ideal for simple straight pulls, especially in thin elements.

Spread Anchors: Designed to distribute loads over a wider area, reducing stress in thinner panels.

Materials and Load Classes

Lifting anchors are typically made of forged steel and are available in various load classes, ranging from 1.3 tons to over 32 tons. All high-quality lifting anchors, like those produced by HULK Metal, comply with CE and TUV standards and are manufactured with a minimum 3x safety factor.

Installation Guidelines

Anchors should be installed according to the designer's layout.

Depth and orientation must be accurate to prevent instability during lifting.

Anchors must be properly secured and supported during concrete pouring.

How Lifting Clutches Ensure Safe and Quick Lifting

While lifting anchors provide the embedded point of connection, Lifting Clutches are the mobile devices that engage with the anchor to actually perform the lift.

Structure and Mechanism

A lifting clutch usually consists of:

A clutch head, precisely engineered to fit with specific anchor types.

A shackle, sometimes flat-sided, to prevent slippage.

A locking bolt or lever, allowing quick and secure attachment, even when wearing gloves.

Key Benefits

Quick connection: Allows operators to engage/disengage rapidly, saving time on site.

Universal compatibility: When using standard systems, a single clutch can work across multiple anchors of the same series.

High safety margin: Designed to match the anchor’s capacity and exceed working load requirements.

On-Site Usage

Operators simply insert the clutch head into the anchor recess, rotate to lock, and begin lifting. Once the element is in place, the clutch can be released just as easily.

The Role of Recess Formers in Accurate Anchor Placement

Often overlooked, Recess Formers play a vital role in ensuring the lifting process is fast and efficient. They are responsible for shaping the cavity in the concrete surface where the lifting clutch will later engage the anchor.

Types and Materials

Rubber Recess Formers: Flexible and reusable, perfect for round or curved applications.

Plastic Recess Formers: Lightweight and cost-effective for one-time use.

Steel Recess Formers: Durable and precise, ideal for repetitive use in large-scale projects.

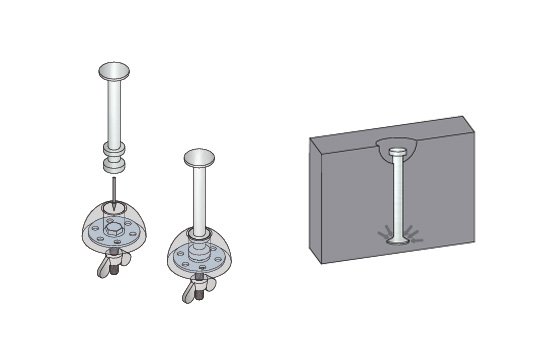

Installation Method

Before concrete pouring, the recess former is fixed to the formwork at the exact location of the lifting anchor. Once the concrete is cured and the formwork is removed, a perfectly shaped recess remains, allowing the lifting clutch to access the anchor safely and easily.

Benefits

Precise alignment: Ensures clutch can engage without obstruction.

Reduced damage: Prevents chipping or cracking around anchor heads.

Speed: Eliminates time-consuming chiseling or locating efforts.

How These Three Components Work Together Onsite

To fully appreciate the efficiency of the system, let’s walk through a typical application process combining these three components:

Step-by-Step Workflow

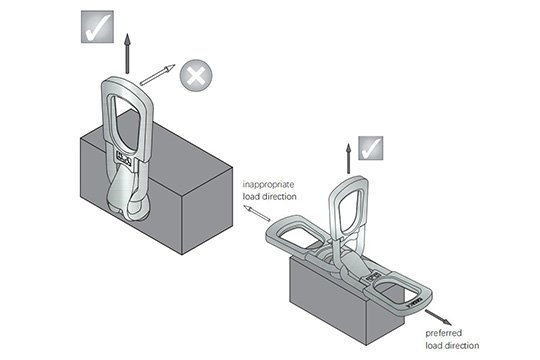

Design and Planning

Choose the appropriate lifting anchor based on load, panel size, and lifting direction.

Select a matching clutch and recess former.

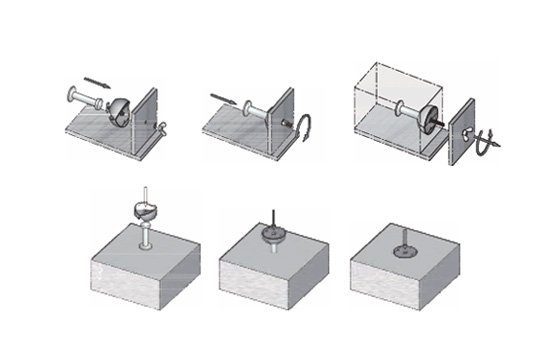

Precast Production

Fix the recess former on the formwork.

Secure the lifting anchor to reinforcement steel at the right depth and angle.

Pour and vibrate concrete, ensuring no air pockets near the anchor.

Formwork Removal

Once cured, remove the formwork to reveal the formed recess.

Clean and inspect the anchor for damage or debris.

Lifting Operation

Insert the lifting clutch into the recess and lock onto the anchor.

Conduct a test lift to confirm secure engagement.

Perform the final lift to transport or install the concrete element.

Post-Lift

Disengage the clutch.

Reuse the clutch and former for subsequent lifts.

System Advantages

Seamless Integration: Components are designed to work together as a complete system.

Time Efficiency: Reduces manual alignment, drilling, or chipping.

Worker Safety: Reduces accidents by enabling reliable and fast connections.

Common Mistakes and How to Avoid Them

Even the best systems can underperform if installed incorrectly. Here are some frequent errors:

Mistake | Impact | Prevention |

Misaligned recess former | Clutch cannot engage anchor | Use templates or jigs for accurate placement |

Wrong anchor depth | Reduces load capacity | Follow manufacturer installation drawings |

Unmatched clutch/anchor pair | Risk of slippage or failure | Always verify compatibility |

Debris in recess | Improper clutch engagement | Clean all recesses before lifting |

Proper training and quality control protocols can eliminate 90% of these issues.

Why Choose HULK Metal as Your Reliable Supplier

At HULK Metal, we don’t just manufacture components—we deliver complete lifting solutions. Here’s why our customers across Europe, Asia, and North America trust us:

Customization Capability

Whether your project requires standard components or fully customized anchors based on architectural drawings, we can deliver tailored solutions at scale.

Certified Quality

All lifting anchors and clutches are:

Forged from high-tensile alloy steel

Heat-treated for durability

Tested under real load conditions

Certified by CE, TUV, and SGS

Complete Supply Chain

From raw material sourcing to precision forging, finishing, testing, and packaging, we manage the entire process in-house to guarantee consistency and reliability.

Global Logistics Support

Our export team has over 20 years of experience in international logistics. We offer:

Flexible packaging options

Quick turnaround times

Support for urgent project schedules

Dedicated Service Team

You’ll have access to our:

Technical advisors for product selection and design support

Production managers to track order progress

After-sales team to resolve any issues swiftly

Precast lifting isn’t just about lifting concrete—it’s about doing it right. Using Lifting Anchors, Lifting Clutches, and Recess Formers as an integrated system is the key to safe, fast, and flawless concrete handling.

When you choose HULK Metal, you gain more than just parts—you gain a partner who understands the entire process from design to delivery.

Ready to optimize your next project?

Contact HULK Metal today and request a tailored precast lifting solution.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.How to Choose High-Quality Shuttering Magnetic Products and Suppliers Guide

- 2.Applications and advantages of swivel hoist rings: HULK Metal provides you with safer and more flexible lifting solutions

- 3.Understanding Load Capacity: A Guide to Lifting Anchor Strength

- 4.Lifting Clutch VS Lifting Ring Clutch:Definition, Working Principle, Application Scenarios, and Selection Guide

- 5.Lifting Anchors: An Essential Component in Construction and Heavy Lifting

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.