How Efficient Precast Accessories Improve Construction Productivity?

In the constantly evolving construction industry, efficiency is more than a goal—it is a necessity. With the growing demand for shorter project timelines, reduced costs, and superior build quality, efficient precast accessories have emerged as essential elements in modern construction workflows. These components are specifically designed to optimize installation processes, enhance safety, reduce labor dependency, and ultimately contribute to seamless project execution.

Efficient precast accessories are transforming how construction projects are approached by minimizing on-site complexities and maximizing the advantages of prefabrication. In this article, we will explore why these accessories are crucial, how they improve productivity, and why partnering with a trusted supplier like HULK Metal ensures unmatched project success.

The Need for Efficiency in Precast Construction

The traditional construction process is often riddled with challenges such as labor shortages, unpredictable weather delays, safety hazards, and escalating project costs. Even with precast concrete's advantages over cast-in-place methods, the efficiency of installation and handling still largely depends on the quality and design of the accessories used.

Common Challenges in Precast Projects

Time-Consuming Installations: Without efficient lifting anchors or magnetic systems, aligning and securing precast elements can require significant time and manpower.

Higher Labor Costs: Manual processes demand skilled labor, driving up operational expenses.

Inconsistent Quality: Variations in accessory quality can lead to errors, rework, or compromised structural integrity.

Safety Risks: Inefficient accessories increase the likelihood of accidents and equipment damage.

Addressing these pain points requires accessories that are purpose-built to simplify installation, enhance strength, and offer precision fitment—hallmarks of efficient precast accessories.

Types of Efficient Precast Accessories

Several categories of precast accessories have been engineered to address productivity challenges. Below are some of the key products making a significant impact in the industry.

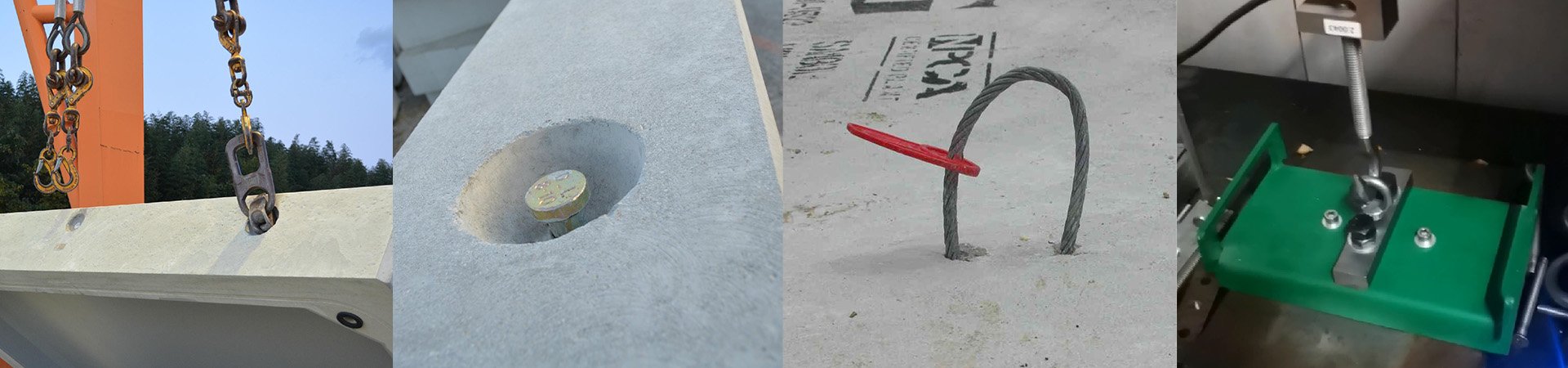

Lifting Anchors

Lifting anchors are critical for the safe and effective handling of precast concrete elements. Efficient designs incorporate features such as:

Quick installation sockets that reduce setup time.

Anti-rotation mechanisms for secure lifting.

Load-tested systems ensure compliance with safety standards.

Magnetic Shuttering Systems

Magnetic shuttering systems are revolutionizing how formwork is positioned and secured:

Strong neodymium magnets provide firm adhesion to steel formwork.

Adjustable positioning allows for faster alignment.

Reusable components reduce waste and material costs.

Wire Rope Lifting Loops

These accessories offer flexibility and strength for various lifting scenarios:

High tensile steel construction supports heavy loads with ease.

Pre-installed options save time on job sites.

Minimal maintenance requirements simplify logistics.

Precast Insert Magnets

Insert magnets are essential for securing fixing points or embedded parts in precast panels:

Precise positioning eliminates guesswork during assembly.

Durable casing withstands harsh construction environments.

Corrosion-resistant coatings extend lifespan and reliability.

Lifting Systems for Panels

Dedicated lifting systems designed for large precast panels or segments include specialized lifting eyes and clutch systems:

Ergonomic connection designs minimize installation errors.

Heavy-load capacity certifications guarantee safety compliance.

Compatibility with various panel designs allows for project flexibility.

How Efficient Accessories Boost Productivity

Efficient precast accessories deliver measurable advantages in productivity, impacting both the short-term execution and long-term success of construction projects.

Faster Installation Times

With optimized designs, accessories like lifting anchors and magnetic systems reduce the steps required for secure attachment. This translates into significant time savings for each individual unit and scales up exponentially across large projects.

Labor Cost Reduction

By streamlining installation processes, fewer workers are required for complex operations. Additionally, training requirements are simplified because efficient systems are intuitive and user-friendly.

Enhanced Site Safety

Purpose-built lifting systems and fail-safe mechanisms reduce the risk of accidents, protecting both workers and equipment. Improved safety records contribute to fewer project delays and lower insurance premiums.

Higher Accuracy and Consistency

Efficient accessories are manufactured with precision, ensuring consistent results in installation and alignment. This reduces the need for on-site adjustments and rework, preserving valuable project resources.

Reduced Project Costs

By combining savings from labor, reduced rework, and material reuse, efficient precast accessories help drive down total project expenses. Over time, these savings significantly enhance the profitability of precast construction ventures.

Why Choose HULK Metal for Efficient Precast Accessories?

The benefits of efficient precast accessories are maximized when sourced from a reliable, experienced supplier. HULK Metal stands out in the industry for several key reasons:

Complete Supply Chain Management

HULK Metal controls every aspect of the supply chain, from raw material sourcing to final delivery. This ensures consistent quality, on-time shipments, and competitive pricing.

Advanced Manufacturing Facilities

With access to modern production lines, CNC machining centers, and forging equipment, HULK Metal delivers products that meet or exceed international quality standards.

Strict Quality Control Systems

Each accessory undergoes rigorous inspection processes, including:

Load Testing: Each lifting component is subjected to calibrated hydraulic and mechanical tests, verifying performance under conditions that exceed standard working loads. These stress tests confirm the accessory’s reliable strength and load-bearing capacity.

Dimensional Inspections: Utilizing precision coordinate measuring machines (CMM) and laser scanning technology, we validate every critical dimension and angle. This meticulous approach guarantees perfect alignment and seamless integration on-site.

Surface Treatment Checks: After galvanizing, plating, or powder coating, samples undergo salt spray, adhesion, and thickness tests to confirm corrosion resistance and coating integrity, ensuring long-term durability in harsh environments.

Global Experience

With years of successful partnerships across Europe, North America, Australia, and Southeast Asia, HULK Metal brings global expertise to every project.

Comprehensive Customer Support

From initial consultation to after-sales assistance, HULK Metal's dedicated teams provide expert guidance at every stage of your project.

Real-World Impact: Project Success Stories

HULK Metal has contributed to the success of numerous infrastructure, residential, and commercial developments worldwide. Case studies consistently demonstrate:

30% faster project completion rates compared to conventional systems.

Reduced error margins in installation thanks to precision-manufactured accessories.

Positive feedback from construction managers on ease of use and time savings.

In an industry where margins are slim and deadlines are tight, choosing efficient precast accessories is a strategic decision that pays dividends across the lifecycle of your project. By improving installation times, reducing costs, enhancing safety, and ensuring consistent results, these accessories enable construction teams to work smarter, not harder.

For businesses seeking dependable solutions, HULK Metal provides the experience, infrastructure, and commitment necessary to drive construction productivity to new heights. Contact our team today to discover how we can help streamline your next project.

Contact Us Today for Customized, Efficient Precast Accessory Solutions!

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

- 1.How to Choose High-Quality Shuttering Magnetic Products and Suppliers Guide

- 2.Applications and advantages of swivel hoist rings: HULK Metal provides you with safer and more flexible lifting solutions

- 3.Lifting Clutch VS Lifting Ring Clutch:Definition, Working Principle, Application Scenarios, and Selection Guide

- 4.Lifting Anchors: An Essential Component in Construction and Heavy Lifting

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.