Construction Shuttering Magnet Supplier

Description:

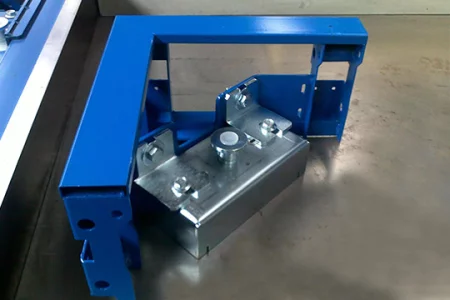

Precast concrete magnets, also known as shuttering magnets, have become indispensable in modern civil engineering due to their efficiency and versatility. These magnets are ideal for securing various precast concrete formwork structures, offering a reusable and reliable solution that streamlines the construction process. Each magnet comprises a durable metal casing, a robust magnetic system, and a user-friendly button mechanism for effortless activation and deactivation. By providing a consistent and secure hold, precast concrete magnets enhance the precision and quality of concrete elements, leading to reduced labor costs and increased productivity on construction sites.

Dimensions and Tolerances of Precast Concrete Shuttering Magnet

| NAME | HULK Metal Precast Magnets | |||

| Item No. | Adhesive Force | Item Size | Net Weight | |

| HM-SMB-600 | 600KG | 17*6*4cm | 1.8KG | |

| HM-SMB-800 | 800KG | 19*9*4cm | 3.0KG | |

| HM-SMB-900 | 900KG | 19*9*4cm | 3.2KG | |

Features of Precast Concrete Shuttering Magnet:

-

Higher Quality Precast Concrete Shuttering Magnet:

Efficiency:

The formwork magnet firmly fixes the formwork on the steel workbench through strong magnetic force, without the need for traditional mechanical fixing methods. This not only simplifies the installation process, but also significantly shortens the production preparation time and improves production efficiency.

Flexibility:

The formwork magnet can be freely positioned according to different prefabricated component sizes and shapes, suitable for various complex design requirements. This flexibility makes the production process more adaptable to diverse architectural designs and meets personalized construction requirements.

Environmental protection:

The use of formwork magnets does not require drilling or welding on the workbench, avoiding damage to the workbench surface and extending the service life of the equipment. At the same time, it reduces the impact on the environment and conforms to the concept of sustainable development.

Cost-effectiveness:

Although the initial investment of formwork magnets may be higher than traditional fixing methods, its advantages in improving production efficiency and reducing equipment maintenance and replacement costs make it show significant cost-effectiveness in long-term use.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Precast Concrete Shuttering Magnet with Shorter Lead Time:

Rigorous Production Process

HULK Metal strictly follows a precise production process, and each link is strictly inspected to ensure that the products meet high standards. From raw material screening to finished product delivery, the factory performs multiple tests, including dimensional accuracy, strength testing and durability evaluation. We use advanced manufacturing processes such as hot forging and CNC machining to ensure that the products have excellent mechanical properties and long-term stability.

Experienced Manufacturing Team

HULK Metal has an experienced manufacturing team covering multiple fields such as production, quality inspection, technology research and development, and supply chain management. The team members have an average of more than ten years of industry experience and are able to accurately control production parameters, improve manufacturing efficiency, and provide professional technical support to customers. With deep industry accumulation, we are able to respond quickly to customer needs, provide customized solutions, and ensure the high quality and reliability of products.

State-of-the-Art Production Machinery

We are equipped with advanced production equipment, including high-precision CNC lathes, multi-axis machining centers, automated forging lines, etc. This equipment not only improves production efficiency but also ensures product consistency and accuracy. In addition, we continue to invest in new technologies and introduce intelligent detection systems and automated production technologies to reduce errors, improve product quality, and shorten delivery cycles.

Considerate Logistics Service

HULK Metal provides comprehensive logistics services, covering product packaging, transportation solution optimization, customs clearance, and after-sales support. We work with internationally renowned logistics companies to ensure that goods can be delivered safely and on time to customers around the world. At the same time, we provide flexible transportation methods, including sea, air, and multimodal transport, to meet the needs of different customers. In the event of quality problems or insufficient quantity, we respond quickly and provide replacement or replenishment services to protect customer interests.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Precast Concrete Shuttering Magnet With Better Service:

24/7 Support

At HULK Metal, we believe in being there for our clients around the clock. Our 24/7 customer support ensures that whether you face a technical issue or have a simple inquiry, assistance is just a call or click away. This commitment to being accessible at all times enhances customer trust and satisfaction, helping us maintain strong, long-lasting relationships with our clients.

Production Monitoring

We implement robust production monitoring processes to guarantee that every product meets the highest standards. By overseeing every stage of the manufacturing process, from raw material selection to final quality checks, we ensure precision, consistency, and on-time delivery. Our continuous monitoring allows us to detect potential issues early, ensuring smoother production runs and fewer delays.Quality Assurance

Quality assurance is at the core of our operations. Our dedicated quality control team performs comprehensive checks at each production phase, ensuring that all products meet international standards. We use advanced testing equipment and precise protocols to inspect the durability, functionality, and overall quality of our products. This commitment to excellence ensures reliability and customer satisfaction.Long-term Partnership

Building long-term partnerships is a priority for us at HULK Metal. We focus on cultivating strong, mutually beneficial relationships with clients, ensuring that our services and products align with their evolving needs. By offering custom solutions, consistent support, and quality products, we work towards becoming a trusted partner for years to come, helping our clients achieve their business goals.You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable of Precast Concrete Shuttering Magnet:

Maximizing Quality and Cost Efficiency:

In today's competitive construction market, striking a balance between quality and cost is essential. By utilizing advanced materials and modern manufacturing techniques, businesses can deliver high-quality products while optimizing production costs.

Holistic Cost Management:

Effective cost management requires a comprehensive approach that spans across all business operations. By tracking every aspect of spending—from raw materials to labor and logistics—businesses can identify potential savings and make informed decisions.

Cultivating a Distinct Brand Identity:

A strong brand identity is more than just a logo or slogan; it's the embodiment of your company’s values, mission, and the unique proposition it offers. A well-crafted brand resonates with customers, building trust and loyalty.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Magnets You Might Want to Know

Besides precast concrete shuttering magnets, we also provide Lifting Clutch, Spread Anchors, Spherical Head Lifting Anchors, Lifting Sockets, and Recess Formers. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Precast Magnets in Blogs

Here is the introduction, production, and quality inspection of the precast magnet that we can organize, as well as some sharing from customers and details of our delivery. You can message us to share or get some content about precast magnets.

-

January 31, 2024Precast Concrete Factory Tells You Why Choose Electric Box Fixing Magnets?

January 31, 2024Precast Concrete Factory Tells You Why Choose Electric Box Fixing Magnets?The electric box fixing magnets emerges as a transformative solution, offering many advantages such as stability, flexibility, ease of use and cost savings.

-

November 16, 2023Precast Magnets: Revolutionizing Formwork Fixation

November 16, 2023Precast Magnets: Revolutionizing Formwork FixationThe magnetic box stands out as a specialized magnetic fixing device designed explicitly for securing precast concrete formwork.

-

November 09, 2023Shuttering Magnets: The Pinnacle of Precast Concrete Formwork Solutions

November 09, 2023Shuttering Magnets: The Pinnacle of Precast Concrete Formwork SolutionsShuttering magnets represent a remarkable innovation in the realm of precast concrete construction.

Reviews

-

Diego Nanini

Earnest is very responsive. The product delivered on time and received in good condition.