Detailed comparison and analysis of rubber recess former and magnetic recess former

In precast concrete production, recess formers play a key role. This type of efficient tool is mainly used to form grooves in concrete, which is convenient for the subsequent installation of lifting anchors and ensures the safety of the lifting process. At present, there are two main types of recess formers on the market: rubber recess formers and magnetic recess formers. Both have their own characteristics in terms of materials, usage methods, and application scenarios. This article will deeply analyze their structure, accessories, advantages and disadvantages, and help you choose the right product according to your actual needs.

Rubber recess former

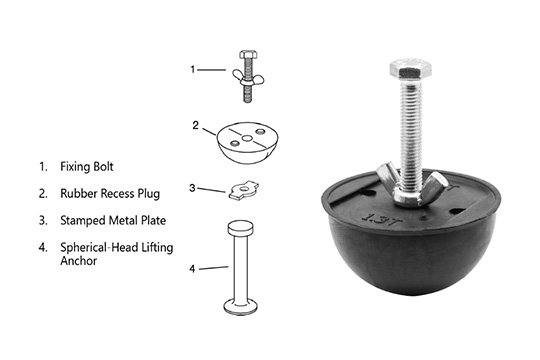

Definition and structure

Rubber recess formers are made of high-strength rubber, and their elasticity and molding devices are ideal for the production of small and medium-sized precast parts. This recess former is usually round or other shapes and is used for manufacturing in concrete, followed by bolt installation for subsequent processing.

Accessories used with it

Fixing bolts

Fixing bolts is one of the accessories of rubber recess formers. With fixing bolts, recess formers can be quickly installed on the mold to prevent movement during concrete pouring.

Stamped Metal Plate

The filler metal plate provides additional support for the recess former, enhancing its ability to resist deformation. Especially in thicker concrete molds, it can effectively maintain the shape of the recess former.

Lifting anchor

The rubber recess former is usually used in conjunction with standard lifting bolts, and its flexibility makes bolt installation and bearing connection more convenient.

Advantages

High elasticity

The rubber material can withstand greater deformation without damage, which makes it suitable for molds with complex shapes.

Low cost

Compared with inferior recess formers, rubber recess formers are expensive to manufacture and are particularly suitable for projects with limited budgets.

Can be used multiple times

As long as it is properly guaranteed, the rubber recess former can be recycled many times, further reducing production costs.

Typical application scenarios

Production of small and medium-sized prefabricated parts, such as floor slabs, walls, etc.

The scenario where the mold needs to be pointed out, such as architectural decorative parts.

Magnetic recess former

Definition and structure

A magnetic recess former is a precast concrete tool with a strong magnet as a fixed core, and its body is usually made of high strength. This type of recess former is designed for high load and position lifting requirements and can easily be equipped with lifting bolts from 1.3 tons to 10 tons.

Accessories

Vehicle bolt terminals of various specifications

The magnetic recess former can be used with various types of embedded bolts to adapt to different load requirements.

Optional center bolt

In some scenarios where higher stability is required, the center bolt can be used to further enhance its fixing ability.

Advantages

Easy installation

Due to the magnetic fixation, the magnetic recess former requires additional screws or screws for installation, reducing the possibility of mold damage.

High reusability

The combination of high-strength steel and magnets makes this product extremely durable and suitable for long-term use in large-scale production.

Accurate positioning

The magnetic fixation method ensures the accurate positioning of the Recess Form, which helps to improve the quality and efficiency of prefabricated parts production.

Typical application scenarios

The production of large prefabricated parts, such as bridge components, subway tunnel components, etc.

For scenarios with high positioning accuracy requirements, such as structural parts of high-rise buildings.

Comprehensive comparison and selection suggestions

Structure and material comparison

The main material of the rubber groove former is rubber high strength, its flexibility and durability, suitable for complex molds. The magnetic groove former is composed of magnets and magnets, which is more suitable for high load and large-scale production needs.

Cost analysis

In short-term projects, the cost of the rubber groove former can meet the limited budget. For long-term use or large-scale production, although the initial investment of the magnetic groove former is higher, its durability and efficiency significantly reduce the long-term cost.

Recommended usage scenarios

Rubber groove former

Suitable for small and medium-sized prefabricated parts production.

For budget-sensitive projects.

Magnetic groove former

Large prefabricated parts or high-load scenarios.

Projects with high requirements for production efficiency and positioning accuracy.

Why choose HULK Metal as your supplier?

HULK Metal is a trusted manufacturer and supplier of precast concrete and related accessories, with a reputation for excellent product quality and customer service. Here are the key reasons to choose HULK Metal as your supplier:

Excellent Product Quality

HULK Metal is committed to producing high-quality precast concrete accessories, including Rubber Recess Former, Magnetic Recess Former, Lifting Anchor Bolts, etc. We use high-quality raw materials and strictly control the production process to ensure that each product meets international standards. All products are ISO 9001 certified and can meet CE, TUV, and SGS testing requirements.

Advanced Production Capabilities

Our factory is equipped with cutting-edge production equipment, including CNC machine tools, precision casting equipment, and efficient heat treatment systems. This equipment, together with a professional team, ensures high precision and consistency of the products. In addition, we have flexible production capabilities and can provide large-volume or customized solutions according to customer needs.

Strong R&D and Innovation

HULK Metal has an experienced R&D team that focuses on the development of new products and the optimization of existing products. We continue to introduce innovative designs, such as improved magnetic fixings and enhanced anchor systems, to meet the growing needs of our customers.

Strict quality inspection

HULK Metal is equipped with a professional inspection team and advanced inspection equipment to conduct comprehensive quality inspections at every stage from raw materials entering the factory to finished products leaving the factory. We provide tensile tests, corrosion tests, and load test reports to ensure the reliability of each batch of products.

Flexible logistics and after-sales service

As a supplier with 20 years of experience in international logistics cooperation, HULK Metal provides a variety of export packaging and transportation solutions to ensure that the products are intact during transportation. Our after-sales team is on call 24/7 to solve any problems for customers and ensure worry-free cooperation.

Competitive prices and long-term cooperation support

HULK Metal provides highly competitive prices while ensuring product quality to help customers reduce project costs. At the same time, we focus on long-term cooperation with customers and provide flexible payment methods and special discount support for bulk orders.

Environmental protection and sustainable development commitment

We attach great importance to environmental protection responsibilities and take energy-saving and emission-reduction measures in the production process to optimize resource utilization. By choosing HULK Metal, you not only get high-quality products but also contribute to green development.

Rubber groove formers and magnetic groove formers each have their own preferences, and the key is to choose the right product according to actual needs. Rubber groove formers are more suitable for small and medium-sized projects with limited budgets, while magnetic groove formers complement their advantages in large projects with their high load capacity and reusability. For further understanding or customized products, please contact HULK Metal's professional team for support.

Article Navigation

PRECAST CONCRETE ACCESSORIES

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.