How to ensure you buy certified lifting anchors for precast concrete structures

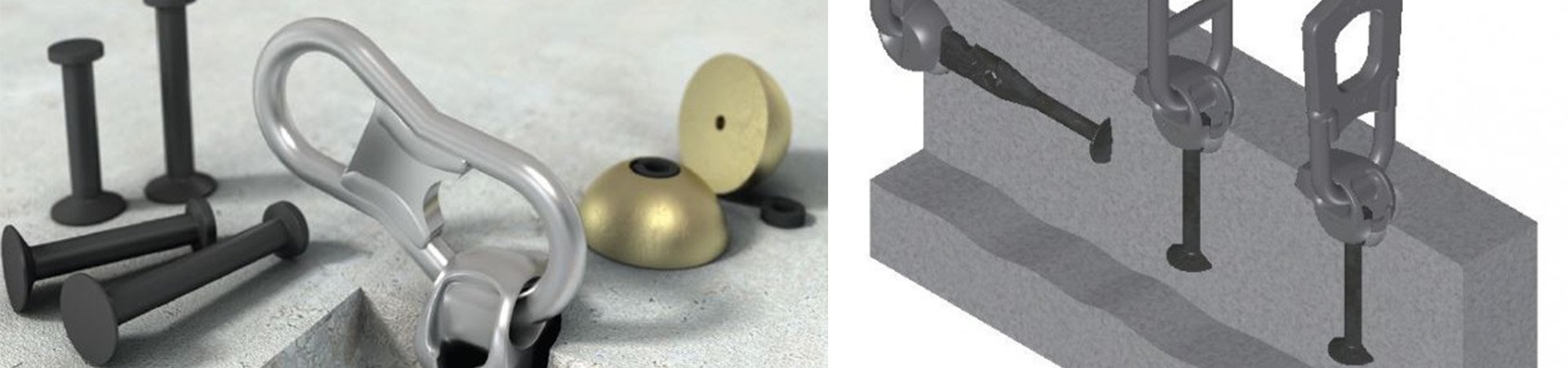

Precast concrete is used in a wide range of applications today – from highways and bridges to buildings and parking lots. It’s durable, efficient and saves time on construction. But before these heavy concrete elements can be installed, they need to be safely lifted and handled. That’s where lifting anchors come in handy. These small but powerful steel components are embedded in the concrete and help lift the concrete safely.

However, not all lifting anchors are the same. Some lifting anchors are safe, reliable and certified, while others may not meet safety standards. Using inferior lifting anchors can lead to dangerous accidents and legal disputes. So how can we ensure you buy certified lifting anchors that meet international standards such as CE and ISO and have a high safety factor (over 3:1). This way, you can avoid problems and keep your team and project safe.

Why are certified lifting anchors important?

Certified lifting anchors are tested and approved to withstand loads exceeding their rated loads and adhere to strict safety regulations.

A certified lifting anchor:

Made from the right steel

Tested for strength and performance

Clearly labeled with safety information

Accompanied by documentation proving compliance with safety regulations

This peace of mind is worth it, especially if there are inspectors, customers, or insurance companies involved.

Understanding certifications: CE and ISO

Let’s break down what the most common certifications actually mean:

CE certification (mostly for Europe)

The CE mark indicates that a product complies with European safety and quality regulations. For lifting anchors, the CE mark indicates that the anchor complies with the EU Machinery Directive, which includes strength, testing, and durability requirements. Any product with the CE mark must be accompanied by a “declaration of conformity”, a document from the manufacturer certifying that the product complies with EU law.

If you import or use lifting anchors in Europe, this certification is not a nice-to-have; it’s a must.

ISO 9001 (a global quality standard)

ISO 9001 doesn’t certify the anchors themselves, but the companies that make them. Companies that are ISO 9001 certified follow consistent processes that ensure quality at every stage of production. For you, this means:

Anchors are manufactured the same way every time

Systems are in place to catch errors

Records are kept for traceability

Buying from an ISO 9001-certified company reduces the likelihood of purchasing a defective or substandard product.

Safety Factor: Why 3:1 is necessary

Here’s a simple way to understand the safety factor:

If an anchor has a safety factor of 3:1 and is rated to hold 1,000 kg, it will only break if it exceeds 3,000 kg. This provides a large safety margin in the event of unexpected loads or small mistakes during lifting.

Why is this important? Because lifting on a construction site is rarely ideal. The angle may be slightly off, cracks may appear in the concrete surface, or the lifting speed may be too fast. All of these can put additional stress on the anchor.

Many countries and companies now require a safety factor of at least 3:1, and sometimes even 4:1 for more critical lifting tasks.

Things to note when choosing a certified lifting anchor

The right material

A strong anchor starts with strong steel. Choose a lifting anchor made of a certified material, such as high-strength carbon steel that meets EN or ASTM standards. Ask for a material certificate, also known as a factory test report, from the factory. This report will tell you what the anchor is made of and how strong it is.

Actual load testing

Reputable manufacturers test their anchors regularly and also test each batch before it is shipped. These tests pull the anchor apart to prove that it is strong enough. Ask for a test report that includes:

When and where the test was conducted

The equipment used

The exact load the anchor took before breaking

Any signs of bending or failure

If the supplier cannot provide this information, it is cause for concern.

Clear marking and traceability

Each anchor should be marked to show:

Manufacturer logo

Load rating (WLL)

CE mark (if applicable)

Batch or serial number

Why are markings important? They help you trace the anchor back to its factory and its test records. If there is a problem, you will know exactly where the anchor came from.

How to check if your supplier is reliable?

Don't just go with the cheapest supplier, you should believe that you get what you pay for. A good lifting anchor supplier should be transparent, helpful, and able to provide documents to support their claims.

Request relevant documents

Before buying, please request:

CE Declaration of Conformity

ISO 9001 certification

Material certificate

Load test report

These documents should match the product you are purchasing, not a generic template.

Visit or video audit the factory

If possible, request a factory tour. If the distance is too far, you can request a live video call. This helps you confirm:

Are they already producing the product?

What is their equipment like?

Do they test every batch?

Is the workspace organized and safe?

A clean, transparent factory is usually a good sign.

Ask for technical help

ISO-certified suppliers often offer engineering support. They can help you with:

Choosing the right anchor size and type

Designing your lifting layout

Doing calculations to make sure everything is safe

Customizing anchors for special jobs

Why is HULK Metal the trusted name in lifting anchors?

At HULK Metal, we have spent years perfecting our lifting anchors. Here’s why our customers trust us:

Certified and documented quality

ISO 9001 certified manufacturing

CE-compliant lifting anchors

Each anchor is tested to a safety factor of 3:1 or more

Full documentation with every order

Strict quality control from start to finish

Raw materials are inspected upon arrival

Our production process includes multiple checks

We load test samples from every batch

All test data is stored and traceable

Engineering support and fast global delivery

Our engineers will help you choose the right anchor

We provide design drawings, lifting solutions, and load calculations

We support special orders and custom designs

We ship worldwide and handle all logistics and documentation

Choose certified anchors for peace of mind

Your lifting system carries a heavy load – no doubt about it. Don’t save money by choosing low-cost, non-certified anchors. Make sure your lifting anchors meet the following requirements:

CE and/or ISO certified

Tested to a minimum 3:1 safety factor

Properly marked for traceability

Provide verifiable documentation

Choosing the right supplier means you get anchors that are safe, reliable, and legal to use. It also avoids future problems such as failed inspections or dangerous lifting incidents.

Let HULK Metal help

We are more than just a manufacturer; we are your lifting partner. Our team is dedicated to helping you find the right anchors, meet deadlines, and keep your project safe.

Let us complete your project with peace of mind.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.