Are You Using the Right Lifting Pin Anchor for Your Precast Project?

In precast concrete construction, the importance of selecting the right lifting pin anchor is often underestimated. At the same time, it may seem like a minor detail, but an inappropriate lifting pin anchor can cause costly delays, jobsite accidents, or even structural failure. With growing demands for faster and safer installations, choosing the correct lifting pin anchor has never been more critical. This article goes beyond product specifications and focuses on the practical selection logic, helping engineers, contractors, and quality inspectors ensure they're using the right lifting pin anchor for the right job.

Understanding the Role of Lifting Pin Anchors in Structural Integrity

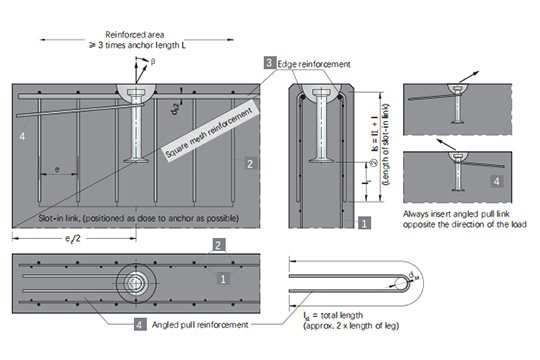

Lifting pin anchors are designed to safely transfer lifting loads from precast elements to cranes through lifting accessories. Their performance relies heavily on how the forces are distributed within the concrete during lifting.

Unlike lifting loops or eye anchors that engage with cable-style clutches, lifting pin anchors use a rigid steel pin system that is inserted into a conical recess. This design allows the lifting force to be transferred more directly and with a shorter embedment depth—making them ideal for thin panels or components with limited concrete coverage.

The lifting pin anchor must be embedded in concrete with enough edge and surface clearance to prevent cracking or cone failure. Therefore, understanding how lifting pin anchors interact with concrete strength, geometry, and lifting angle is vital to project success.

Key Factors in Choosing the Right Lifting Pin Anchor

Before selecting a lifting pin anchor, several variables must be evaluated:

Concrete Strength Class: The lifting pin anchor’s load capacity is directly related to the compressive strength of the concrete at the time of lifting. Lifting before the concrete has reached sufficient strength can lead to failure.

Load Angle Variation: Lifting at an angle greater than the lifting pin anchor’s safe working load (SWL) rating reduces its capacity. Most lifting pin anchors are tested for angled loads up to 45°, but performance drops sharply beyond that.

Anchor Body Size & Recess Compatibility: The selected lifting pin anchor must fit perfectly with its corresponding recess former and lifting clutch. Using mismatched parts compromises both safety and efficiency.

Environmental Conditions: In corrosive environments or marine structures, choosing galvanized or stainless steel lifting pin anchors becomes essential.

Selecting the wrong lifting pin anchor—too small, too shallow, or poorly matched to its clutch—can compromise the entire lifting system.

Hidden Risks: What Goes Wrong When You Choose the Wrong Lifting Pin Anchor

Using the wrong lifting pin anchor isn’t just a technical error—it can be a major safety hazard. Here are common issues that occur:

Cone Failure: When lifting pin anchors are installed too close to the edge or with insufficient embedment, the concrete cone can break under load.

Misalignment: If the lifting clutch is not aligned with the lifting pin anchor axis, additional shear forces are introduced, risking failure.

Load Rating Confusion: On-site mix-ups between lifting pin anchors of similar size but different load capacities can result in under-rated lifts.

Reused Accessories: Reusing worn lifting clutches or recess formers across different lifting pin anchor models can cause poor fits and unstable connections.

Case in point: A project lifting precast staircases failed due to mismatched clutch and lifting pin anchor sizes, causing slippage and a dropped panel. Fortunately, no injuries occurred, but it led to a full halt in site operations for three days.

Tailoring Lifting Pin Anchor Selection to Your Project Type

Different precast components have different lifting challenges. Here’s how to tailor lifting pin anchor selection accordingly:

Architectural Precast Panels: These often have limited embedment depth, requiring smaller yet high-strength lifting pin anchors with precise recess formers to maintain a clean surface finish.

Utility Vaults and Manholes: These elements are heavy and compact. Lifting pin anchors with high axial load resistance and minimal side-load deflection are ideal.

Beams and Columns: Require symmetrical lifting pin anchor placement and exact alignment to avoid rotation during lifting. Longer lifting pin anchors offer better stabilization here.

Selecting lifting pin anchors specific to the component’s structural function is essential to ensure both safe lifting and installation precision.

Compatibility with Lifting Equipment

A lifting pin anchor is only as reliable as the system it integrates with. It’s critical to ensure compatibility with lifting equipment such as:

Lifting Clutches: Each lifting pin anchor requires a corresponding clutch designed to securely lock into the pin head. Using an incompatible clutch can cause load transfer issues or unlocking under tension.

Spreader Beams & Cranes: Lifting equipment must be configured to minimize angular loading and ensure even force distribution across lifting pin anchors.

Certifications: Only use CE-certified and load-tested systems. Unverified components may introduce legal and safety liabilities.

Proper equipment integration not only improves safety but also reduces on-site troubleshooting and delays.

Seamless Integration: Pairing Lifting Pin Anchors with the Right Accessories

To achieve optimal lifting performance, lifting pin anchors must be paired with the correct accessories:

Lifting Clutches: Designed specifically to interface with lifting pin anchors, these clutches feature locking pins and release handles that simplify secure engagement and disengagement. It’s crucial to use clutches tested and certified for the specific lifting pin anchor model.

Recess Formers: These create the conical voids in which the lifting clutch head sits. Choosing the wrong former can result in misalignment or inadequate anchorage depth. HULK Metal offers rubber, steel, and magnetic formers, each suitable for different mold and concrete surface conditions.

Accessory Alignment: Improper clutch-former-anchor alignment can create lifting angle discrepancies, introducing unwanted bending stress or shearing risk.

By treating these accessories as part of an integrated lifting system—not isolated parts—you significantly improve project safety and precision.

Checklist: Are You Using the Right Lifting Pin Anchor?

Here’s a quick checklist to evaluate whether you’re using the correct lifting pin anchor:

Have you verified the concrete compressive strength at lifting?

Is the lifting pin anchor load-rated for your component's weight and angle?

Are you using matching recess former and lifting clutch?

Does the lifting pin anchor meet CE/EN standards?

Is the embedment depth sufficient for the applied load?

Is the lifting pin anchor free from corrosion or physical damage?

Are lifting operations supervised by qualified personnel?

Have you reviewed lifting pin anchor spacing and edge distances?

Has the lifting system been tested on similar components?

Have you consulted with your lifting pin anchor supplier for technical validation?

If you answered “No” to any of these, it’s time to reassess your lifting system.

HULK Metal’s Lifting Pin Anchor

HULK Metal specializes in the manufacturing of high-performance lifting pin anchors tailored to the demands of the precast concrete industry. Our products are manufactured using high-strength alloy steel, forged with precision to ensure optimal mechanical properties and structural reliability.

We offer a wide range of sizes and load classes, with options for hot-dip galvanizing, zinc plating, and stainless steel finishes, making our anchors suitable for both indoor and harsh outdoor environments. Every lifting pin anchor is rigorously tested to meet CE standards and other international lifting safety requirements.

What sets HULK Metal apart:

In-house forging and CNC Machining Center

Custom Produce available based on client drawings and specifications

100% inspection before delivery

Clutch and recess former system compatibility guaranteed

Fast global delivery backed by a reliable logistics network

HULK Metal is a trusted precast concrete accessories supplier, serving hundreds of customers across more than 30 countries. We specialize in manufacturing a full range of precast components, including lifting anchors, threaded sockets, spread anchors, lifting devices, and precast concrete magnets—all engineered for strength, precision, and safety.

If you're looking for a reliable lifting pin anchors manufacturer or a partner for competitive precast concrete parts, HULK Metal helps you reduce procurement time and cost while maintaining superior quality.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.