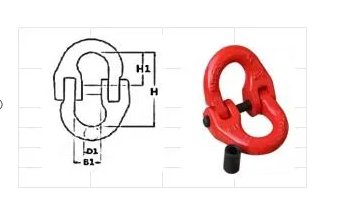

G80 Connecting Link

Description:

The HULK Metal Connecting Link is designed in compliance with EN1677 standards, ensuring high quality and reliability. Made from high-tensile forged alloy steel, it undergoes a quenching and tempering process to enhance its strength and durability. Each link is rigorously tested, including 100% magnaflux crack detection and proof testing at 2.5 times the Working Load Limit (WLL). It boasts a minimum breaking load four times the WLL and undergoes batch testing for further assurance. Additionally, all load pins are subjected to eddy current testing, and the link is fatigue-tested for 20,000 cycles. Finished with a durable powder coating and individually inspected for appearance, this product guarantees optimal performance and safety.

Parameters of G80 Connecting Link:

| Size | Chain | Dimensions(mm) | WL.L. | Weight | |||

| Size(mm) | B1 | D1 | H1 | H | (T) | (KG) | |

| 6-8 | 6 | 15.2 | 7.5 | 18.5 | 45.5 | 1.1 | 0.1 |

| 7/8-8 | 7-8 | 19.2 | 9.0 | 24.0 | 59.5 | 1.5 | 0.2 |

| 10-8 | 10 | 25.0 | 11.8 | 28.0 | 69.8 | 3.2 | 0.3 |

| 13-8 | 13 | 30.0 | 15.0 | 36.5 | 89.0 | 5.3 | 0.7 |

| 16-8 | 16 | 36.0 | 19.0 | 41.0 | 102.0 | 8.0 | 1.2 |

| 18/20-8 | 20 | 42.0 | 23.0 | 49.0 | 119.0 | 12.5 | 1.8 |

| 22-8 | 22 | 49.0 | 24.5 | 63.0 | 152.5 | 15.0 | 3.1 |

| 26-8 | 26 | 58.5 | 31.5 | 69.0 | 1624 | 21.2 | 5.3 |

| 32-8 | 32 | 67.5 | 38.5 | 79.0 | 194.0 | 31.5 | 9.4 |

| Minimum Breaking load=4×WLL(Working load Limited) | |||||||

Features About Parameters of G80 Connecting Link:

-

Higher Quality G80 Connecting Link:

Material Strength

The HULK Metal Connecting Link is crafted from high-tensile forged alloy steel, ensuring exceptional strength and durability. This robust material allows the link to withstand heavy loads and harsh conditions, making it ideal for demanding applications.

Safety Assurance

Safety is a top priority, with each Connecting Link undergoing extensive quality checks. It’s proof-tested at 2.5 times its Working Load Limit (WLL) and batch-tested for a minimum breaking load of four times the WLL. These rigorous tests ensure the safety and reliability of every link.

Surface Protection

For added protection, the Connecting Link is powder-coated, enhancing its resistance to corrosion, wear, and environmental damage. This surface finish ensures the longevity of the product, even in challenging outdoor environments.

Wide Application

The versatile design of the Connecting Link makes it suitable for a wide range of applications in industries such as construction, lifting, and material handling. Its robustness ensures reliable performance across various use cases.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

G80 Connecting Link With Shorter Lead Time:

Rigorous Production Process

Our Connecting Links are manufactured through a precise and controlled process, involving quenching, tempering, and fatigue testing for up to 20,000 cycles. This ensures that every product meets the highest standards of quality and performance.

Experienced Manufacturing Team

The experienced team at HULK Metal applies decades of industry knowledge to produce the highest-quality Connecting Links. Their expertise ensures that each link meets all necessary specifications and quality benchmarks.

State-of-the-Art Production Machinery

We use the latest production machinery, ensuring that every Connecting Link is forged with precision and consistency. Advanced equipment also enables fast production times without compromising on quality.

Considerate Logistics Service

HULK Metal offers reliable logistics services to ensure your Connecting Links are delivered promptly and safely. With a focus on efficiency, we provide tailored solutions for timely and secure shipments.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

G80 Connecting Link With Better Service:

24/7 Support

We provide round-the-clock customer support to address any inquiries or issues. Whether it’s technical assistance or order tracking, our team is always available to provide expert help and ensure your satisfaction.

Production Monitoring

Every phase of production is closely monitored to guarantee that all standards are met. From material selection to final inspection, we ensure the highest levels of quality control throughout the manufacturing process.

Quality Assurance

At HULK Metal, quality is our commitment. Each Connecting Link undergoes rigorous testing, including magnaflux crack detection and proof testing, to ensure it meets the highest performance and safety standards.

Long-term Partnership

We aim to build long-term relationships with our customers. By consistently delivering top-tier products and exceptional service, HULK Metal strives to be a trusted partner in your business growth.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable G80 Connecting Link:

Maximizing Quality and Cost Efficiency

Our streamlined manufacturing processes and bulk production capabilities allow us to offer the best value for money, without compromising on quality. We focus on optimizing both cost efficiency and product excellence.

Cultivating a Distinct Brand Identity

HULK Metal is committed to cultivating a brand identity based on trust, reliability, and quality. Our focus on superior products and customer satisfaction sets us apart in the industry.

Versatility in Application

The HULK Metal Connecting Link’s design makes it adaptable to a variety of industries, ensuring that it can handle diverse operational needs. From lifting to construction, its versatility makes it an invaluable component in many applications.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Concrete Accessories You Might Want to Know

Besides lifting swivel hooks, we also provide Spherical Head Lifting Anchors, Lifting Clutch For Concrete, and Recess Formers For Lifting Anchors. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About G80 Connecting Link In Blogs

Here is the introduction, production, and quality inspection of swivel points that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a message if you want to share or get some content about the lifting clevis hooks.

-

April 07, 2025Different Types of Lifting Hooks

April 07, 2025Different Types of Lifting HooksIf you are planning your next lifting project, there are many things to think about—especially when choosing your lifting gear, such as the type of sling and its associated components. Hooks are a very crucial element when it comes to lifting loads, and there is a wide selection to choose from.

-

April 03, 2025Safety Guide to Your Lifting Hooks

April 03, 2025Safety Guide to Your Lifting HooksIn today’s fast-paced industrial environment, ensuring safety during lifting operations is paramount. Whether you’re using cranes, hoists, or slings, the lifting hook is one of the most critical components in the rigging process.

-

April 01, 2025Application of Precast Magnets in the Production of Precast Concrete Components

April 01, 2025Application of Precast Magnets in the Production of Precast Concrete ComponentsPrecast concrete components have revolutionized modern construction by offering efficiency, precision, and consistency. These prefabricated elements, including walls, slabs, beams, and columns, are produced in controlled environments and then transported to construction sites for assembly.

-

March 18, 2025Key Factors in Choosing a Precast Concrete Lifting Clutch

March 18, 2025Key Factors in Choosing a Precast Concrete Lifting ClutchPrecast concrete elements are widely used in modern construction due to their efficiency, strength, and durability. However, ensuring the safe and effective lifting of these heavy components requires high-quality lifting clutches.

-

March 12, 2025How to use lifting anchors correctly: ensuring construction safety and efficiency

March 12, 2025How to use lifting anchors correctly: ensuring construction safety and efficiencyIn the process of lifting precast concrete components, lifting anchors play a vital role. As part of the lifting tools, lifting anchors can not only effectively support and transfer loads, but also ensure the safety and efficiency of the lifting process.

Reviews

-

Zoe Cooper

The HULK Metal Connecting Link is incredibly strong and reliable. Excellent build quality, rigorous testing, and fast delivery. Highly recommended for heavy-duty applications!