2.5t Concrete Lifting Clutch

Description:

Constructing safe and efficient precast structures requires high-performance lifting components to ensure accuracy under load. The HULK Metal 2.5t Concrete Lifting Clutch is a professional-grade tool designed specifically for the lifting and transport of precast components. Each Concrete Lifting Clutch is manufactured in our ISO 9001 certified factory and features robust connectors for precise mating with foot anchors. Advanced metal forging processes ensure a safety factor of at least 5, far exceeding the safety standards of commonly used European lifting solutions.

Parameters of HULK Metal 2.5t Concrete Lifting Clutch:

| NAME | MATERIAL | Q345D / Q355D / CM490 / G30CrMoV / Customizable | ||

| Concrete Panel Lifters | SURFACE TREATMENT | Electro-galvanized | ||

| SAFETY FACTOR | ≥ 5 | |||

| CERTIFICATE | ISO9001 / CE | |||

| SWL (tons) | CODE | LENGTH(mm) | WEIGHT(kg/pc) | |

| 1.3 | HM-PC-013 | 165 | 1.0 |

| 2.5 | HM-PC-025 | 205 | 1.7 | |

| 5.0 | HM-PC-050 | 240 | 3.6 | |

| 10.0 | HM-PC-100 | 346 | 9.8 | |

| 20.0 | HM-PC-200 | 520 | 24.5 | |

| 32.0 | HM-PC-320 | 590 | 45.0 | |

Features About 2.5t Concrete Lifting Clutch:

-

Higher Quality 2.5t Concrete Lifting Clutch:

What’s 2.5t Concrete Lifting Clutch Introduction

Concrete Lifting Clutches, also known as Lifting Eyes or Dog Bone Lifting Eyes, are professional-grade attachment links engineered for the secure handling and transportation of precast concrete elements. Manufactured in our ISO 9001-certified factories,each lug consists of a precision-cast steel head, a forged or heat-bent steel ring, and a high-strength bar, which are welded and assembled for maximum load-bearing capacity.

Introduce

MATERIAL:Q345D / Q355D / CM490 / G30CrMoV / Customizable

SURFACE TREATMENT:Electro-galvanized

SAFETY FACTOR:≥ 5

CERTIFICATE:ISO9001 / CE

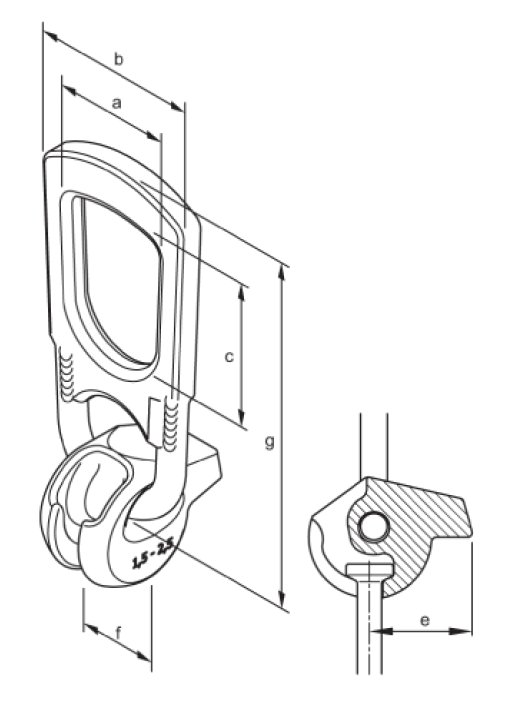

Structure

Head

The head is precision cast from high-grade alloy steel, ensuring superior strength and wear resistance. Its central opening allows the steel ring to pass through, while internal grooves securely lock the lifting anchor into place.

Ring

The ring is manufactured from alloy steel using a controlled hot bending process, passing through the central opening of the anchor head and permanently welded to the bar. This structure provides high tensile strength and reliable load transfer, suitable for demanding lifting applications.

Bar

The bar is made from durable alloy steel and precisely cut to the required dimensions. One end is securely welded to the steel ring, while the other end forms a closed loop, allowing for a safe and stable connection to a standard hook.

Assembly

During assembly, high-strength bars are hot-bent, passed through the steel ring, and then welded using advanced argon arc welding. This process ensures consistent weld quality, excellent structural integrity, and long-term reliability under repeated lifting cycles.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

2.5t Concrete Lifting Clutch with Shorter Lead Time:

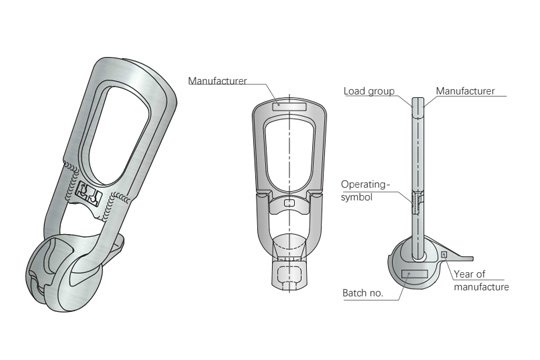

Each Lifting Clutch has identification markings as shown.

The front of the handle is stamped with the name of the manufacturer and the

identification,

The rear of the handle shows the load group and an operating icon.

How Does a 2.5T Concrete Lifting Clutch Work?

The 2.5T concrete lifting clutch connects precisely with a compatible lifting anchor embedded in precast concrete elements. Once engaged, the clutch head locks firmly onto the anchor, ensuring a secure and stable connection throughout the lifting process.

The integrated bar or ring is attached to the crane hook, allowing lifting forces to be evenly transferred from the hook to the anchor. This balanced load distribution minimizes stress concentration and ensures safe, controlled handling of precast components.

Safety Considerations

The Safe Working Load (SWL) must always meet or exceed the lifting requirements.

The load group of the clutch must match the selected lifting anchor.

All lifting lugs must comply with international standards such as CE.

Each clutch is tensile tested with a minimum safety factor of 5:1.

Applications

2.5T lifting clutches are widely used for lifting precast beams, slabs, wall panels, pipes, stair units, and other concrete components in residential, commercial, and infrastructure projects.

Key Advantages

CE certified and ISO 9001 quality assurance

High load capacity with a 5× safety factor

Zinc-plated surface for enhanced corrosion resistance

Fast production cycles and reliable delivery

Professional technical support and responsive after-sales service

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

2.5t Concrete Lifting Clutch with Better Service:

Quality Inspection Services

Each lifting clutch is strictly inspected, including material verification, dimensional checks, and tensile testing with a minimum five-times safety factor to ensure compliance.

Packaging Services

Export-standard packaging protects lifting clutches during transport, with clear labeling and flexible packing options available to meet different shipping and handling requirements.

After-Sales Service

Professional after-sales support provides technical guidance, fast response to quality issues, and reliable solutions to ensure safe and efficient long-term use.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable 2.5t Concrete Lifting Clutch:

Higher Quality 2.5T Concrete Lifting Clutch

Manufactured from high-strength alloy steel and strictly inspected, the 2.5T concrete lifting clutch ensures stable performance, precise engagement, and reliable safety under demanding precast lifting conditions.

All-Round Cost Control

Integrated supply chain management, optimized production processes, and efficient material sourcing help control manufacturing and logistics costs while maintaining consistent quality and competitive pricing.

Shaping Your Brand Image

Consistent product quality, professional documentation, and reliable delivery support your brand reputation, helping you build long-term customer trust in competitive construction and precast markets.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Concrete Lifting Lugs You Might Want to Know

Besides Precast Concrete Lifting Lugs, we also provide Spherical Head Lifting Anchors, Lifting Clutch For Concrete, and Recess Formers For Lifting Anchors. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Concrete Panel Lifters in Blogs

Here is the introduction, production, and quality inspection of concrete panel lifters that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a message if you want to share or get some content about concrete panel lifters.

-

August 20, 2025Selecting the Right Lifting Accessory for Different Precast Applications

August 20, 2025Selecting the Right Lifting Accessory for Different Precast ApplicationsThe efficiency and safety of precast concrete installation depend not only on the precision of the concrete elements themselves but also on the lifting systems used to handle them. Every precast unit—whether it is a wall panel, a structural beam, or a compact architectural detail—requires the correct lifting accessory to ensure secure handling and minimize risks during transport and installation.

-

August 12, 2025Everything You Need to Know About Lifting Anchor Systems

August 12, 2025Everything You Need to Know About Lifting Anchor SystemsIn the precast concrete industry, details determine success or failure—especially when it comes to lifting and handling heavy components. Whether installing wall panels, beams, columns, or bridge sections, you need reliable equipment. One of the most important tools is the lifting anchor system.

-

August 06, 2025ISO Certified Precast Concrete Accessories Factory in China

August 06, 2025ISO Certified Precast Concrete Accessories Factory in ChinaWhen it comes to sourcing precast concrete accessories, finding a reliable, high-quality manufacturer is everything. From lifting sockets and wire loop boxes to spread anchors and cast-in channels, your project’s structural integrity depends on the components you choose.

-

June 26, 2025How Lifting Anchors, Lifting Clutches, and Recess Formers Work Together in Precast Lifting

June 26, 2025How Lifting Anchors, Lifting Clutches, and Recess Formers Work Together in Precast LiftingPrecast concrete construction is a rapidly growing solution in modern infrastructure due to its speed, quality, and efficiency. However, lifting and placing heavy concrete components require more than just raw power—it requires precision, safety, and well-matched accessories.

Reviews

-

Michael Thompson

I’ve used the 2.5T Concrete Lifting Clutch on multiple precast projects. Engagement is secure, lifting is stable, and overall quality fully meets our site safety requirements.