Ring Clutch Lifting System

Description:

The Ring Clutch Lifting System from HULK Metal is designed to provide safe, efficient, and flexible lifting solutions for precast concrete elements. We offer a complete range of lifting clutches, including lifting eye ring clutches, concrete panel lifting clutches, and wire loop ring clutch. Backed by a fully managed factory and advanced molds, we can supply CE-certified products from 1.25 tons to 32 tons. Every ring clutch undergoes strict quality inspections based on a 5x safety factor. With complete quality assurance and faster delivery, HULK Metal ensures you receive reliable, cost-effective lifting systems tailored to your project’s needs.

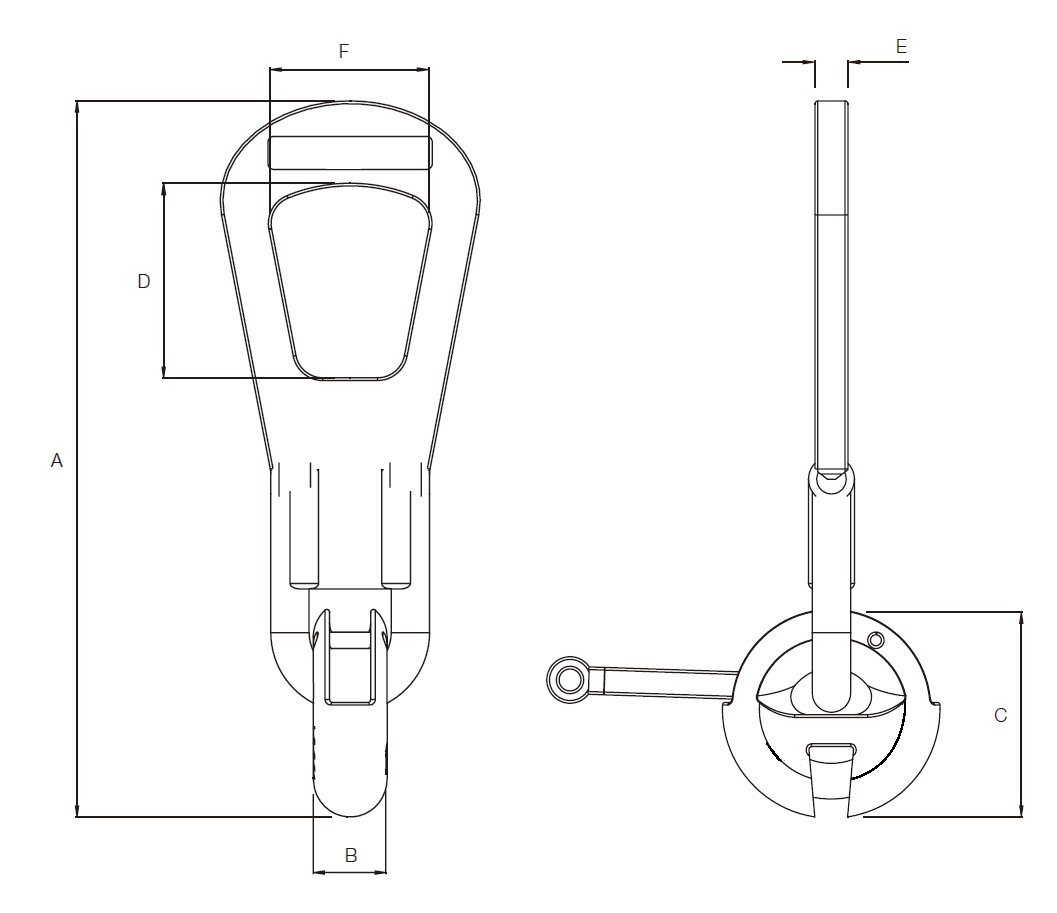

Parameters of HULK Metal Ring Clutch Lifting System:

| NAME | MATERIAL | Q345D / Q355D / CM490 / G30CrMoV / Customizable | |||||

| HULK Metal Ring Clutch | SURFACE TREATMENT | Electro-galvanized | |||||

| SAFETY FACTOR | ≥ 5 | ||||||

| CERTIFICATE | ISO9001 / CE | ||||||

| SWL (tons) | CODE | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | |

| 2.5 | RC025-261 | 261 | 27 | 80 | 70 | 50 |

| 5.0 | RC050-330 | 330 | 36 | 100 | 86 | 71 | |

| 10.0 | RC100-425 | 425 | 50 | 140 | 112 | 90 | |

| 26.0 | RC260-605 | 605 | 72 | 209 | 160 | 120 | |

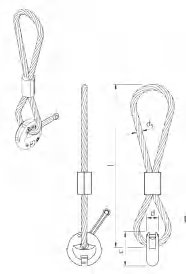

| NAME | MATERIAL | Q345D / Q355D / CM490 / G30CrMoV / Customizable | ||||

| Wire Loop Ring Clutch | SURFACE TREATMENT | Electro-galvanized | ||||

| SAFETY FACTOR | ≥ 5 | ||||

| CERTIFICATE | ISO9001 / CE | |||||

| SWL (tons) | CODE | LENGTH(mm) | C(mm) | D(mm) | DS(mm) | |

| 1.25 | RC0125-20-0320 | 320 | 52 | 20 | dia. 8 | |

| 2.5 | RC0250-27-0560 | 560 | 80 | 27 | dia.14 | |

| 5.0 | RC0500-27-0595 | 595 | 105 | 36 | dia.18 | |

| 10.0 | RC1000-50-0702 | 702 | 150 | 50 | dia.22 | |

| 26.0 | RC2600-72-1570 | 1570 | 206 | 72 | dia.32 | |

Features About Ring Clutch Lifting System:

-

Higher Quality Ring Clutch Lifting System:

All types of ring clutch lifting systems from HULK Metal share several key advantages:

CE Certified, with rigorous quality control.

High Safety Factor: Tested at 5x the working load.

Premium Materials: 35CrMoV alloy, forged bolts, precision-cast components.

Advanced Manufacturing: Deep welding (X-ray approved), laser cutting, heat-bending processes.

Efficient Installation: Simple connect/disconnect mechanism, ensuring fast and safe lifting.

Versatile Load Capacity: Available from 1.25 tons to 32 tons.

Lifting Eye Ring Clutch

The lifting eye ring clutch is designed for lifting heavy precast concrete components with embedded anchors. It features a forged lifting eye, curved bolt, and strong clutch body. The curved bolt locks securely into the anchor, ensuring stable and safe lifting. Its design allows multi-directional movement, improving flexibility during handling. With precision forging and casting, it provides excellent strength and reliability for repeated use in demanding construction environments.

Concrete Panel Lifting Clutch

Concrete panel lifting clutches with chain are used to lift large precast concrete panels efficiently. The clutch consists of a cast head, forged bolt, and chain. The chain is made by heat bending and welding. Its robust structure ensures safe handling of heavy loads. The forged parts use high-grade alloy steel for superior performance. Each clutch is designed for quick connection with the anchor, speeding up lifting processes while maintaining safety. Precision welding and strict testing guarantee dependable performance on every job site.

Wire Loop Ring Clutch

The wire loop ring clutch combines a durable clutch body with a flexible steel wire rope for fast, reliable lifting. It features a swaged wire rope, curved bolt, and laser-cut handle with a large cavity for hook placement. The handle is marked with the corresponding load group for easy identification. This design allows quick installation by rotating the bolt to lock or release. It’s ideal for lifting various precast elements, offering convenience and repeatable safety.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

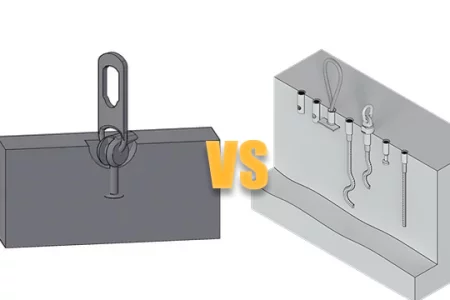

Ring Clutch Lifting System Application and Installation:

Application:

The Ring Clutch Lifting System is specifically designed for lifting precast concrete elements equipped with embedded lifting anchors. Each ring clutch is engineered to precisely match its corresponding anchor type and load group, ensuring a secure and efficient connection. This system is widely used in lifting concrete panels, walls, and other precast structures in construction projects, providing a dependable solution for safe material handling.

How it works:

1.Positioning:

Align the ring clutch directly above the head of the compatible spread anchor before installation.

2. Engagement:

Insert the clutch into the recess, push downward to seat the clutch on the anchor head, and rotate the curved bolt to lock securely in place.

3. Removal:

To release the clutch after lifting, rotate and pull the curved bolt out of engagement, allowing easy detachment from the anchor.

4. Concrete Cover:

Maintain a minimum concrete cover of at least 20mm between the anchor’s base and the concrete surface to prevent corrosion and ensure long-term durability.

5. Safe Lifting Practices:

Ensure lifting forces remain aligned with the centerline of the bail during use. Avoid contact between the bail and concrete edges to prevent deformation or damage during lifting.

This system provides a fast, repeatable, and safe connection for handling various precast concrete units in lifting operations.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Ring Clutch Lifting System with Better Service:

Dedicated and Professional Customer Service Team:

Our experienced customer service team provides expert guidance, personalized solutions, and prompt responses to ensure every project runs smoothly from inquiry to delivery, building long-term trust with our clients.

24/7 Service:

We offer 24/7 customer support to respond to inquiries, provide technical assistance, and handle urgent needs, ensuring your projects stay on schedule regardless of time zones or deadlines.

Tracking and Feedback:

Real-time order tracking and timely feedback allow customers to monitor production, packaging, and shipping status, providing complete transparency and improving coordination throughout every stage of the process.

Quality Assurance Services:

Every order is backed by comprehensive quality assurance, including rigorous inspections, material certification, and detailed reports, ensuring the delivered products meet or exceed customer expectations and international standards.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable Ring Clutch Lifting System:

Higher Quality with Lower Risk:

Choosing certified, high-quality ring clutches not only ensures lifting safety but also reduces the long-term risk of failure, lowering hidden costs from potential rework, downtime, or site accidents.

Effective Cost Management:

Investing in durable lifting systems minimizes replacement frequency. By selecting reliable products from trusted suppliers, users can better control operational budgets while maintaining performance standards on construction projects.

Strengthen Brand Reputation:

Using certified, well-inspected lifting equipment reflects your company’s commitment to safety and professionalism. This enhances your brand image in the industry, builds client confidence, and supports long-term business growth.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Concrete Accessories You Might Want to Know

Besides Lifting Clutch, we also provide Precast Magnets, Spread Anchors, Spherical Head Lifting Anchors, Lifting Sockets, and Recess Formers. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Lifting Ring Clutch in Blogs

Here is the introduction, production, and quality inspection of Lifting Ring Clutch that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a message if you want to share or get some content about Lifting Ring Clutch.

-

June 20, 2025Lifting Sockets vs Lifting Anchors: Which Is Better for Precast Concrete?

June 20, 2025Lifting Sockets vs Lifting Anchors: Which Is Better for Precast Concrete?Precast concrete has become one of the key materials in modern construction. Whether you are working on large infrastructure projects or building residential developments, using precast concrete components can significantly improve efficiency, consistency, and safety on-site.

-

February 08, 2025Lifting Clutch and Ring Clutch: Key equipment to ensure the safety and efficiency of lifting operations

February 08, 2025Lifting Clutch and Ring Clutch: Key equipment to ensure the safety and efficiency of lifting operationsIn modern construction, manufacturing, and transportation industries, lifting operations are an integral part of daily operations. Whether it is transporting heavy machinery, hoisting precast concrete components, or handling large equipment, choosing the right lifting equipment is essential to ensure safe operations and improve work efficiency.

-

August 31, 2023Guide to clutch Maintenance and Care: Ensuring Safe and Efficient Operations

August 31, 2023Guide to clutch Maintenance and Care: Ensuring Safe and Efficient Operationsclutches are indispensable equipment in industrial production, responsible for crucial tasks such as material handling and lifting.

-

August 29, 2023How to maintain the shuttering magnet in the application of precast concrete?

August 29, 2023How to maintain the shuttering magnet in the application of precast concrete?In the realm of prefabricated concrete structures, the fixed magnetic box stands as a crucial connecting element, employed to secure molds or templates in their designated positions prior to concrete casting.

-

August 24, 2023Precast Concrete Accessories: Advantages and Modern Applications

August 24, 2023Precast Concrete Accessories: Advantages and Modern ApplicationsAs an expert in precast concrete accessories, I will provide you with a comprehensive overview of the concept, benefits, and contemporary applications of these components.

Reviews

-

Steve Mills

We’ve been using the Ring Clutch Lifting System from HULK Metal for several projects, and the quality has consistently exceeded our expectations. The installation is quick, the safety factor is reliable, and their customer service is outstanding. Highly recommended.