Comprehensive Guide to Wavy Tail Anchor Manufacturing

The Wavy Tail Anchor is a vital component used in precast concrete construction. It plays a key role in ensuring structural integrity, especially in load-bearing applications. Designed with a distinctive wavy pattern at the tail end, this anchor achieves superior bonding with concrete and delivers exceptional performance under stress. As the demand for reliable anchoring systems grows in modern construction, selecting a trustworthy and experienced manufacturer becomes crucial.

HULK Metal, a leading name in metal forging and construction accessories, specializes in the production of Wavy Tail Anchors. With advanced manufacturing capabilities and a deep understanding of industry requirements, HULK Metal provides durable, precise, and cost-effective solutions that meet global standards.

Understanding the Function and Design of Wavy Tail Anchors

The Role of Wavy Tail Anchors in Precast Construction

Wavy Tail Anchors are embedded into precast concrete panels to provide a secure and efficient method for anchoring the panels to structural frames or other panels. They ensure load transfer and help the structure withstand various mechanical stresses during transportation, installation, and long-term use.

Key Design Features

Wavy Tail Design: The undulating tail increases the bonding area with concrete, enhancing pull-out strength and preventing slippage.

Threaded or Plain Shank: Depending on the application, the anchor may feature a threaded or smooth shaft to accommodate bolts or welding plates.

Mechanical Strength: Made from high-strength steel, Wavy Tail Anchors are engineered to support heavy loads without deformation or breakage.

Materials Commonly Used

Carbon Steel: Offers excellent strength and cost-efficiency for general-purpose use.

Stainless Steel: Provides corrosion resistance in harsh or outdoor environments.

Surface Coatings: Zinc plating or hot-dip galvanization is applied to improve rust resistance and extend service life.

Wavy Tail Anchor Manufacturing Process

At HULK Metal, manufacturing Wavy Tail Anchors involves a meticulous, multi-step process that ensures every piece meets rigorous quality and performance standards.

Raw Material Selection

High-quality steel billets and rods are sourced only from certified suppliers. The selected material must meet mechanical property requirements such as tensile strength, elongation, and hardness. HULK Metal's procurement team ensures material traceability and consistent quality from batch to batch.

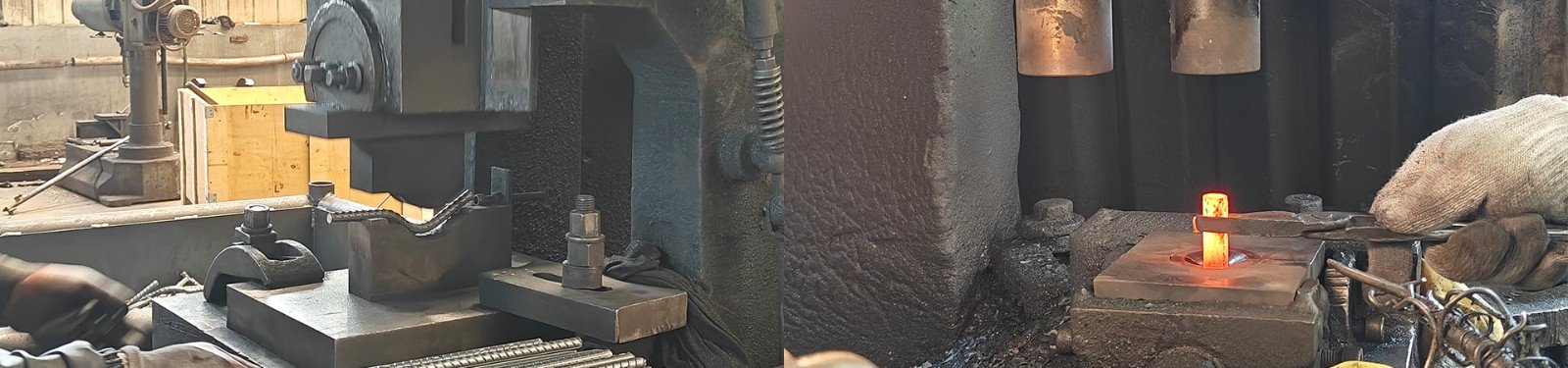

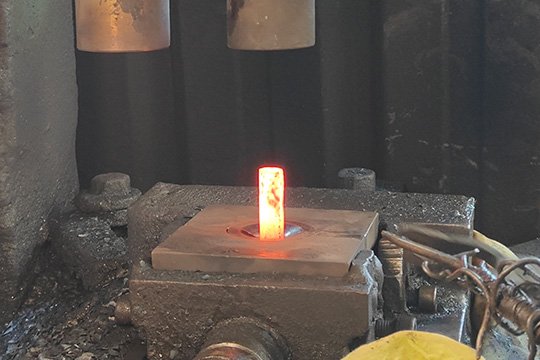

Forging Process

HULK Metal employs hot forging as the primary method for shaping the anchors. The metal is heated to its plastic state and then forged into the desired shape using precision dies. Forging offers significant advantages over casting, such as:

Higher strength due to refined grain structure

Better fatigue resistance

Reduced risk of internal defects like porosity

The wavy tail is formed using specially designed tooling that ensures consistent geometry across all parts.

CNC Machining

After forging, each anchor undergoes CNC machining to achieve tight dimensional tolerances. Threaded sections, chamfers, and surface finishes are precisely executed to guarantee compatibility with nuts, bolts, or concrete formwork accessories.

Custom machining options are also available to accommodate different installation designs or regional standards.

Surface Treatment

To enhance corrosion resistance and extend the lifespan of the anchors, several finishing options are available:

Zinc Plating: Offers mild corrosion protection and a clean appearance.

Hot-Dip Galvanizing (HDG): A thicker, more robust protective layer ideal for outdoor or marine environments.

Epoxy Coating: Optional coating for specialized applications requiring high chemical resistance.

Quality Inspection

HULK Metal follows a rigorous quality assurance protocol:

Dimensional inspection using calipers and gauges

Mechanical testing (pull-out strength, tensile strength)

Visual inspection for cracks, deformities, or surface defects

All testing results are documented, and full traceability is maintained throughout the production cycle.

Advantages of High-Quality Wavy Tail Anchors

Investing in premium Wavy Tail Anchors from HULK Metal delivers long-term value for construction professionals.

Superior Bonding with Concrete

The unique tail profile increases the mechanical interlock with cured concrete, enhancing the anchor’s grip and reducing pull-out risks. This ensures safer structural connections, especially in high-load or seismic zones.

Enhanced Structural Integrity

Reliable anchoring improves overall building stability. HULK Metal’s anchors are designed to resist tensile, shear, and vibrational stresses, protecting the structure from unexpected failures.

Reduced Installation Time and Costs

Consistent design and accurate dimensions simplify on-site installation. Workers can rely on standardized dimensions, reducing rework and accelerating the building schedule.

Longer Lifespan and Lower Maintenance

Surface treatments like HDG prevent corrosion and rust, reducing the need for frequent replacements or repairs. This lowers long-term maintenance costs for contractors and end-users.

Customization and OEM Capabilities by HULK Metal

HULK Metal is not just a manufacturer but a strategic partner offering tailored solutions for global clients.

Custom Dimensions and Thread Types

Whether your project requires metric threads, custom diameters, or extended lengths, HULK Metal can deliver. Engineers collaborate closely with clients to ensure compatibility with specific formwork systems or installation conditions.

Design Assistance and Engineering Support

From design drawings to prototype development, HULK Metal offers expert consultation to optimize anchor performance based on application and load requirements.

Quick Prototyping and Mass Production

Thanks to in-house tooling and CNC capability, sample delivery can be completed in a matter of days. Once approved, large-scale production follows strict timelines without compromising quality.

Export-Ready Packaging and Documentation

Each order can be customized with:

Customer logos or part numbers

Individual or bulk packaging options

Full documentation, including test reports, certificates, and HS codes

Quality Control and Certification

ISO 9001 Certified Production

HULK Metal's factory is ISO 9001 certified, ensuring all production steps adhere to international quality management standards.

Full Quality Tracking System

Every part is assigned a batch number for complete traceability. From raw material sourcing to final inspection, all data is recorded and reviewable.

Third-Party Testing

Upon request, products can be tested and certified by independent labs such as SGS or TUV. These services are often used for large-scale infrastructure projects or government contracts.

Complete Documentation Support

Customers receive full documentation, including:

Material certificates

Mechanical test reports

Coating thickness measurements

Dimensional inspection records

Applications of Wavy Tail Anchors

HULK Metal’s Wavy Tail Anchors are suitable for a wide range of structural applications:

Precast Concrete Panels: Ideal for curtain walls, partition walls, and sound barriers

Façade Anchoring Systems: Ensure secure connection between decorative cladding and building structure

Bridge and Tunnel Linings: Resistant to vibration and heavy loading

Architectural Cladding: Provide discreet and strong attachment points for aesthetic panels

Why Choose HULK Metal for Wavy Tail Anchor Production?

When you partner with HULK Metal, you gain more than just a supplier—you gain a trusted expert with a full-service approach.

20+ Years of Experience

With decades of experience in forging and construction hardware, HULK Metal understands every nuance of anchor production—from metallurgy to site conditions.

Comprehensive Supply Chain

From raw materials to logistics, HULK Metal controls the full supply chain. This ensures fast lead times, stable pricing, and consistent product availability.

Advanced Manufacturing Equipment

Multi-station hot forging lines

Precision CNC machines

Automated galvanizing and plating systems

All equipment is maintained to international standards for accuracy and efficiency.

Dedicated Engineering and Support Teams

You’ll receive ongoing support from technical engineers, QA specialists, and export documentation staff to ensure smooth project execution.

Global Logistics and On-Time Delivery

HULK Metal works with top-tier freight forwarders to provide sea, air, and land transport. Consolidated shipping, real-time tracking, and customs support are standard.

Competitive Pricing with Uncompromised Quality

Thanks to scale manufacturing and optimized processes, HULK Metal offers premium products at highly competitive prices, backed by robust warranties and responsive after-sales service.

Let’s Build Stronger Together

The Wavy Tail Anchor may be small in size, but its role in structural safety is critical. From precast walls to complex architectural panels, choosing a high-quality anchor makes a lasting difference.

With a commitment to precision, reliability, and customer satisfaction, HULK Metal is ready to support your next project with world-class Wavy Tail Anchors and industry-leading service.

Article Navigation

- 1.Understanding the Function and Design of Wavy Tail Anchors

- 2.Wavy Tail Anchor Manufacturing Process

- 3.Advantages of High-Quality Wavy Tail Anchors

- 4.Customization and OEM Capabilities by HULK Metal

- 5.Quality Control and Certification

- 6.Applications of Wavy Tail Anchors

- 7.Why Choose HULK Metal for Wavy Tail Anchor Production?

- 8.Let’s Build Stronger Together

PRECAST CONCRETE ACCESSORIES