Maximize Site Safety with CE Certified Lifting Anchors for Precast Concrete

In the landscape of modern construction, precast concrete has emerged as the gold standard for industrialization and modularity. From massive bridge girders to intricate architectural wall panels, the transition from onsite pouring to factory-controlled production has revolutionized project timelines. However, the sheer scale of these components—often weighing dozens of tons—presents a critical logistical challenge: moving these "monoliths" safely.

Lifting systems serve as the vital link between the static concrete element and the dynamic forces of cranes and rigging. At the heart of this system lies the lifting anchor. As the primary load-bearing component embedded within the concrete, the quality and design of the anchor determine the safety of the entire lifecycle of the precast element, from de-moulding at the factory to final installation on-site. Utilizing high-quality CE Certified Lifting Anchors for Precast Concrete is no longer just an option; it is a structural necessity.

What Are CE Certified Lifting Anchors?

A CE marking is far more than a regulatory requirement; it is a formal declaration that a product meets rigorous safety, health, and environmental protection standards. For lifting anchors, CE certification implies that the product has undergone exhaustive design calculations, dynamic load simulations, and safety factor verifications.

According to international safety directives, such as the Machinery Directive 2006/42/EC, lifting accessories must demonstrate a specific safety margin. HULK Metal’s range of CE Certified Lifting Anchors for Precast Concrete adheres to a safety factor of at least 3:1 or 5:1, depending on the specific application. Selecting certified anchors ensures that your project complies with global best practices and minimizes legal and operational risks.

Key Functions of Lifting Anchors in Precast Concrete Systems

A professionally engineered lifting anchor performs several critical roles that a simple rebar loop cannot match:

Lifecycle Support: It provides secure attachment points during production, flipping for de-moulding, yard storage, transport, and final positioning.

Optimized Stress Distribution: Advanced designs distribute tensile and shear forces evenly into the concrete, significantly reducing the risk of edge breakouts or structural cracking.

Operational Efficiency: When paired with specialized lifting clutches, these anchors allow for rapid attachment and release, achieving a notable reduction in the man-hours required for crane operations.

Types of CE Certified Lifting Anchors

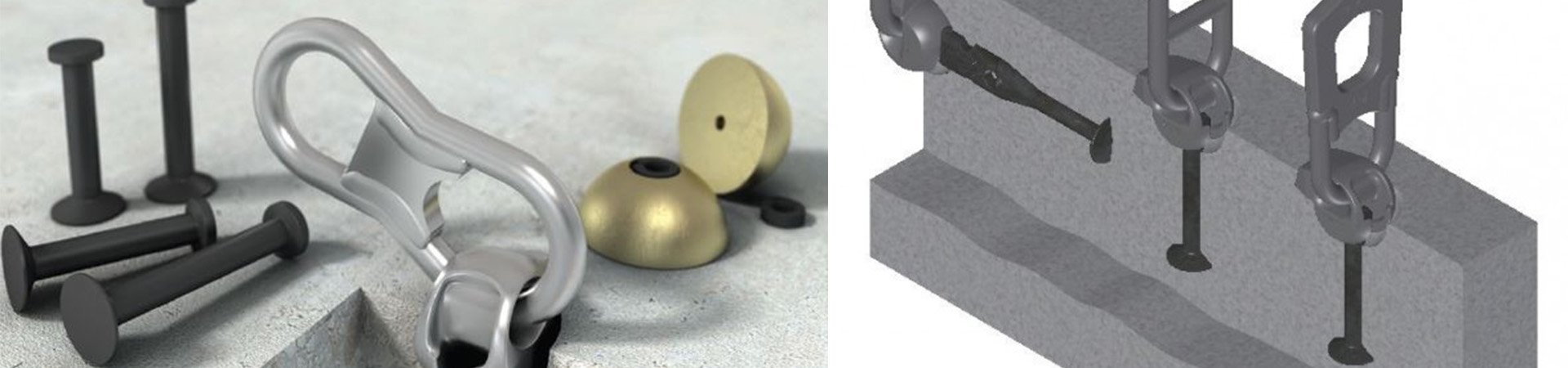

HULK Metal provides a diverse portfolio of CE Certified Lifting Anchors for Precast Concrete tailored to specific structural needs within our specialized factories:

Spherical Head Lifting Anchors: The industry workhorse, available in load classes from 1.3t to 32t. Its symmetrical design allows for effective loading from any direction.

Spherical Double Headed Lifting Anchors: Specifically engineered for increased anchorage depth and higher load requirements, providing enhanced security in complex structural elements.

Lifting Eye Anchors: Used primarily with additional reinforcement bars to handle heavy loads in thin panels or low-strength concrete, ensuring the load is transferred deep into the component.

Utility Lifting Anchors: A versatile solution designed for the quick and efficient lifting of smaller precast elements such as pipes, curbs, and utility vaults.

Materials and Manufacturing Processes

At HULK Metal, superior performance starts with metallurgy. Our anchors are forged from high-grade alloy steels, including 20Mn2, Q345D, and CM490, or stainless steel for corrosive environments.

The manufacturing process is centered on Hot Forging. Unlike machining, which cuts through the grain flow of the metal, hot forging aligns the internal grain structure with the shape of the anchor. This results in significantly higher tensile strength and improved fatigue resistance. Following forging, precision machining ensures that dimensions—especially the head diameter—meet strict tolerances for perfect compatibility with lifting clutches. This meticulous process allows us to maintain a 99.8% qualification rate.

Load Capacity and Safety Considerations

Engineering safety is non-negotiable. The Safe Working Load (SWL) of any CE Certified Lifting Anchors for Precast Concrete is calculated based on several critical variables:

Concrete Compressive Strength: The anchor is only as strong as the concrete holding it. We provide load tables based on concrete strengths at the time of the initial lift.

Direction of Pull: While spherical head anchors handle axial and diagonal pulls well, shear pulls require specific considerations for reinforcement.

Safety Factor Setting: We maintain a robust safety margin, ensuring that the ultimate breaking load is several times the rated SWL to account for dynamic shocks during crane movement.

Quality Control and Testing for CE Certified Lifting Anchors

Operating out of our ISO 9001-certified factories, we implement a "zero-defect" quality management system to ensure every batch meets specific quantity and quality requirements:

Raw Material Traceability: Every batch of steel is accompanied by a Mill Test Certificate (MTC), allowing us to trace every anchor back to its original heat number.

Destructive Testing: We perform regular tension and pull-out tests in our laboratory to ensure the breaking point exceeds the required safety thresholds.

Non-Destructive Testing (NDT): Magnetic particle inspection identifies surface or sub-surface cracks that could lead to catastrophic failure under load.

Compliance with Precast Concrete Standards and Regulations

Our products are designed to harmonize with international codes such as EN 13155 and the VDI/BV-BS 6205 guidelines. Compliance ensures that when an anchor is embedded, its performance is predictable and reliable, satisfying the requirements of structural engineers and site safety officers worldwide.

Common Applications of CE Certified Lifting Anchors

Infrastructure: Bridge segments, tunnel linings, and culverts require anchors capable of handling immense weight under harsh conditions.

Industrial Buildings: Precast columns and heavy-duty floor slabs.

Residential Projects: Wall panels and balcony elements. Our anchors allow for the safe handling of "thin" panels where traditional lifting methods would fail.

How to Select the Right CE Certified Lifting Anchor

Selecting the correct anchor is a technical process involving three main steps:

1. Load Calculation: Determine the weight of the element and apply a "Dynamic Factor" and an "Adhesion Factor" for the mould.

2. Edge Distances: Ensure the anchor is placed far enough from the edges of the concrete to prevent "cone failure."

3. Compatibility Check: Verify that the anchor type matches the available lifting hardware at the construction site.

Why Choose HULK Metal for CE Certified Lifting Anchors?

As an expert in metal forging and precast accessories, HULK Metal offers more than just hardware; we provide peace of mind through an integrated supply chain:

Manufacturing Prowess: Our factories utilize advanced forging lines that ensure consistent quality across millions of units.

Integrated Supply Chain: By managing everything from raw material suppliers to internal logistics, we have achieved a 15% reduction in production cycles.

Customization: Whether you need hot-dip galvanized finishes or custom dimensions, our technical team tailors solutions to your specifications, including customizable packaging.

Reliability Commitment: We guarantee that every batch meets your exact needs. Should any quality discrepancies or shortages occur, we provide full returns, exchanges, and restocking services.

Technical Support: From selection advice to installation guidance, our team of specialists acts as your partner in the precast industry.

By choosing HULK Metal’s CE Certified Lifting Anchors for Precast Concrete, you are investing in a system proven to deliver technical excellence in the global construction market. Submit an inquiry today to see how our expertise can benefit your next project.

Article Navigation

PRECAST CONCRETE ACCESSORIES

OTHER RELATED ARTICLE

Other Precast Concrete Accessories You Might Want to Know

You can click to learn more about HULK Metal precast concrete accessories such as lifting anchors, precast sockets, spread anchors, shuttering magnets, cast-in channels, wire loop boxes, and other precast concrete accessories you might want to know.