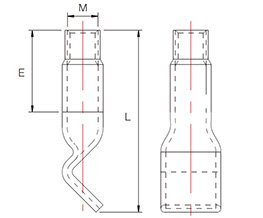

Fixing Socket With Wavy End

Description:

Fixing sockets with wavy ends are essential components designed for reliable and secure fixing applications in concrete structures. Manufactured through a meticulous process involving extruding, bending, and shrinking, these sockets exhibit exceptional structural integrity. The wavy end design enables self-anchoring functionality, ensuring a robust connection within concrete fixing sockets that are strictly intended for fixing purposes and should not be used for lifting. They are engineered to perform effectively under working loads, adhering to a minimum concrete compressive strength of 25 MPa. To ensure quality and safety, each socket undergoes rigorous tensile testing, achieving a safety factor of over three times its rated working load.

Parameters of HULK Metal Fixing Sockets:

| NAME | MATERIAL | Stainless Steel / Q345 / Q235 / 20# / Customizable | ||||||

| Fixing Socket with Bended End | SURFACE TREATMENT | Raw Color, Electro-galvanized, Hot-dip Galvanized | ||||||

| SAFETY FACTOR | ≥ 3 | |||||||

| CERTIFICATE | CE / ISO 9001 | |||||||

| SWL (tons) | CODE | THREAD(M) | L(mm) | E(mm) | ||||

| 0.08 | FWS-M06-030 | 6 | 30 | 10 | |||

| 0.15 | FWS-M06-050 | 6 | 50 | 30 | ||||

| 0.20 | FWS-M08-040 | 8 | 40 | 15 | ||||

| 0.25 | FWS-M08-050 | 8 | 50 | 20 | ||||

| 0.30 | FWS-M10-040 | 10 | 40 | 15 | ||||

| 0.35 | FWS-M10-050 | 10 | 50 | 20 | ||||

| 0.50 | FWS-M12-060 | 12 | 60 | 25 | ||||

| 1.00 | FWS-M16-100 | 16 | 100 | 45 | ||||

| 1.25 | FWS-M20-100 | 20 | 100 | 65 | ||||

Features About Fixing Socket:

-

Higher Quality Fixing Socket:

ISO 9001 Factory:

HULK Metal is committed to providing high-quality Fixing Sockets with Wavy End products for the construction industry. Our production base has passed ISO 9001 quality management system certification to ensure the efficiency and standardization of each production link.

Professional Testing Team And Advanced Testing Instruments:

HULK Metal is equipped with a professional testing team and advanced testing instruments, and conducts comprehensive quality inspections at every step, from raw material selection to finished product delivery. The strict inspection process ensures that Fixing Sockets products meet international standards. Our products are able to pass CE certification, as well as strict inspections by TUV and SGS, providing customers with reliable quality assurance.

Strict Inspection Process:

Fixing Sockets with Wavy End are precisely designed and suitable for a variety of fixing needs in the precast concrete industry. Its corrugated end design enhances the bonding force with concrete, providing higher safety and stability for construction.

Can Pass CE Certification and TUV, SGS Inspection:

Our products are able to pass CE certification, as well as strict inspections by TUV and SGS, providing customers with reliable quality assurance.

Choosing HULK Metal means choosing excellent quality and professional service. We are committed to providing customers with durable Fixing Sockets and providing solid support for your project.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Fixing Sockets with Shorter Lead Time:

Advanced Production Equipment:

HULK Metal is a professional building accessories manufacturer dedicated to providing customers with high-quality fixing sockets with wavy ends. We have advanced production equipment, including CNC machining centers and precision casting equipment, to ensure that the products are manufactured with high precision and consistency.

Experienced Production Team:

Our experienced production team is proficient in complex processes and can design and manufacture products for different application scenarios according to customer needs.

Rigorous Production Process:

We will formulate a complete production solution according to your purchase quantity, quality requirements, delivery time, and other requirements. The production process will be more orderly, and the Flat End Fixing Sockets with Bent End can be done faster.

Thoughtful Freight Service:

You can enjoy free freight consulting services here. We can help you find safer, more cost-effective, and faster freight companies. You can receive goods with high quality and quantity faster.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Fixing Sockets with Better Service:

Dedicated and Professional Customer Service Team:

Our team is committed to providing expert guidance on selecting and utilizing fixing sockets with wavy ends. With extensive industry knowledge, we ensure prompt and efficient communication, delivering tailored solutions to meet the specific needs of every client.24/7 Service:

Understanding the demands of the construction industry, we offer round-the-clock support. Whether it's product inquiries, technical assistance, or order updates, our team is available 24/7 to ensure seamless service and timely responses.Tracking and Feedback:

From the moment an order is placed, we provide comprehensive tracking services. Clients receive real-time updates on their shipments, ensuring transparency. Additionally, we actively gather feedback to refine our products and services continually.Quality Assurance Services:

Our fixing sockets with wavy ends undergo stringent quality assurance checks. Manufactured with precision, these sockets meet international standards, ensuring durability, reliability, and consistent performance in various construction applications.You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-Controllable Fixing Sockets:

Higher Quality and Controllable Cost:

Fixing sockets with wavy ends are manufactured with precision to ensure high load-bearing capacity and durability. Using premium-grade materials and advanced production techniques, these sockets deliver consistent quality. The integration of rigorous quality control processes minimizes defects, ensuring reliable performance in precast concrete applications. Despite their superior quality, our efficient production methods allow for competitive pricing, balancing exceptional quality with cost-effectiveness.

Comprehensive Cost Control:

Through streamlined manufacturing processes, optimized material usage, and bulk procurement strategies, we maintain strict cost control without compromising on product integrity. This approach allows us to offer fixing sockets with wavy ends at a competitive price, supporting client budgets for various construction projects.

Shape Your Brand Image:

By providing reliable and high-performing fixing sockets with wavy ends, we help enhance your brand’s reputation. Superior products translate to improved project outcomes, allowing your brand to be associated with quality, reliability, and innovation in the construction industry.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Fixing Sockets You Might Want to Know

Besides Flat End Fixing Sockets with Wavy Ends, we also offer Flat End Fixing Sockets, Solid Rod Fixing Sockets, Flat Fixing Sockets with Cross Pins, and other fixing sockets. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Fixing Sockets in Blogs

Here is the introduction, production, and quality inspection of Fixing Sockets that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a comment if you want to share or get some content about Fixing Sockets with Wavy End.

-

December 25, 2024Lifting Sockets to Ease the Process of Lifting Precast Elements

December 25, 2024Lifting Sockets to Ease the Process of Lifting Precast ElementsIn modern construction, precast concrete components are widely used due to their high efficiency, energy saving, and sustainability. These components usually need to be hoisted, transported, and installed on the construction site, and lifting sockets are key connectors to ensure the safety, stability, and efficiency of the lifting process.

-

December 02, 2024Application of Lifting Socket in Precast Concrete

December 02, 2024Application of Lifting Socket in Precast ConcreteThe Lifting Socket is a lifting accessory designed for precast concrete components, which plays an important role in modern building construction. Its main function is to seamlessly combine precast concrete components with lifting equipment through safe and reliable connections to achieve efficient transportation and installation.

-

October 23, 2024High-Performance Lifting Loops for Safe and Economical Handling of Precast Concrete

October 23, 2024High-Performance Lifting Loops for Safe and Economical Handling of Precast ConcreteLifting loops are an essential tool in the precast concrete industry, providing a reliable, cost-effective solution for lifting and transporting precast elements such as panels, stairs and beams. These lifting loops are designed to fit into precast lifting eye sockets and provide a secure connection for safe handling of precast concrete units.

Reviews

-

Gold pascal

Very good!