Anchor Recess

Description:

HULK Metal's Anchor Recesses provide the necessary interfaces for safe and efficient lifting operations in precast concrete production. These anchor recesses are carefully designed to form precise grooves during pouring, ensuring a perfect fit with the corresponding lifting anchor. HULK Metal supplies anchor recesses in various materials, sizes, and configurations, supporting different anchor systems. All precast concrete accessories are manufactured under a strict quality control system. Contact us today to meet your mass production or custom project needs.

Parameters of Recess Formers For Lifting Anchors:

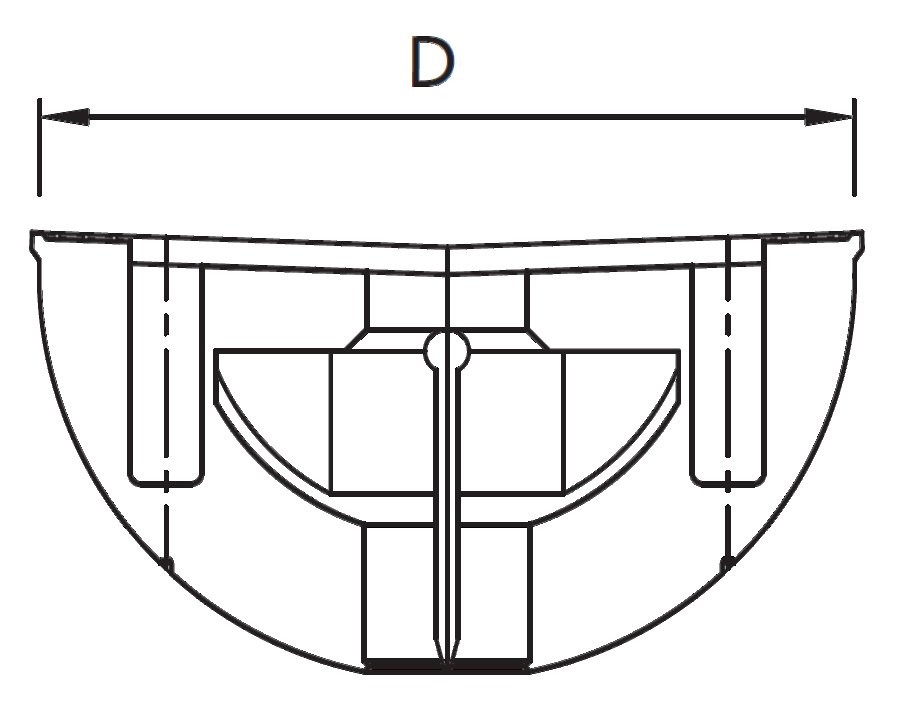

| Name | Pin Anchor Recess Former | ||

| Drawings |  | ||

| Material | Rubber / Customizable | ||

| SWL (tons) | CODE | DIAMETER(mm) | WEIGHT with Bolt(kg/pc) |

| 1.3 | HM-RRF-013 | 60 | 0.1 |

| 2.5 | HM-RRF-025 | 74 | 0.2 |

| 5.0 | HM-RRF-050 | 94 | 0.4 |

| 7.5 | HM-RRF-075 | 118 | 0.6 |

| 10 | HM-RRF-100 | 118 | 0.6 |

| 15 | HM-RRF-150 | 160 | 1.4 |

| 20 | HM-RRF-200 | 160 | 1.5 |

| 32 | HM-RRF-320 | 214 | 3.7 |

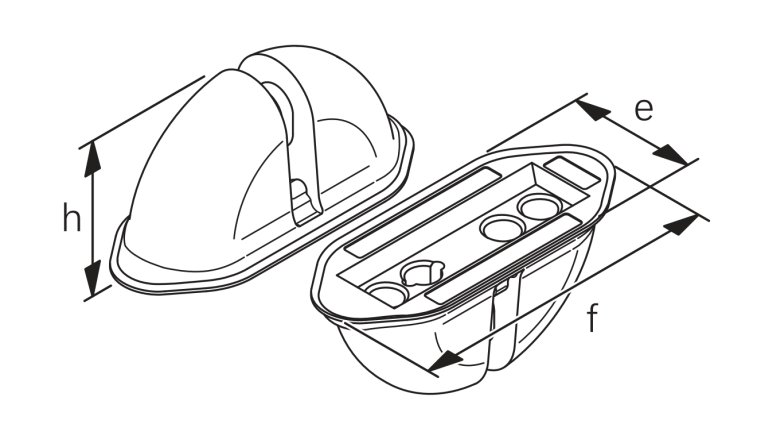

| Name | Spread Anchor Recess Former | ||||

| Drawings |  | ||||

| Material | Rubber / Customizable | ||||

| CERTIFICATE | ISO9001 / CE | ||||

| SWL (tons) | CODE | A(mm) | B(mm) | C(mm) | D(mm) |

| 2.5 | SRF025-105 | 44 | 105 | 45 | M8 |

| 5.0 | SRF050-126 | 49 | 126 | 59 | M8 |

| 10.0 | SRF100-188 | 67 | 188 | 85 | M12 |

| 26.0 | SRF260-234 | 112 | 234 | 118 | M16 |

Features of Anchor Recess:

-

Higher Quality Anchor Recess:

What is Anchor Recess?

In the precast concrete industry, Anchor Recess typically refers to a "recess form" or "groove mold," a crucial positioning component. Its core function is to fix the lifting pin anchor in its predetermined position on the formwork during concrete pouring, forming a precise hemispherical or specifically shaped groove after the concrete has hardened.

This groove is critical: it ensures a perfect fit between the lifting clutch and the lifting pin anchor head, preventing misuse of components with different load ratings and guaranteeing lifting safety.

Type

To maximize structural integrity and lifting safety, HULK Metal designs specialized recess formers tailored to specific anchor systems:

Anchor Recess for Lifting Pin Anchors: These are designed to create the exact spherical cavity required for lifting clutches. By ensuring a precise fit, they prevent lateral movement and distribute stress evenly, maintaining a 99.8% qualification rate across high-volume production.

Anchor Recess for Spread Anchors: Specifically configured for the flat geometry of spread anchors, these formers ensure the lifting eye has sufficient clearance to engage. This configuration is vital for thin-walled panels where placement accuracy is non-negotiable.

Anchor Recess for Lifting Inserts: These facilitate the positioning of threaded inserts. Our engineering team has optimized these designs to prevent concrete slurry from entering the threads, reducing post-casting maintenance by 15% through improved efficiency.

Anchor Recess for Utility Anchors: Designed for versatile, light-duty applications, these formers provide a cost-effective solution for various precast utilities, ensuring consistent performance across diverse project scales.

Material Innovation and Selection

HULK Metal’s integrated supply chain allows us to manufacture recess formers in various materials to meet specific environmental and reuse requirements:

Rubber Anchor Recess: Known for exceptional durability and flexibility, our high-grade rubber formers are designed for multiple reuses. Their elastic nature allows for easy stripping without damaging the concrete edges, maintaining the architectural finish of the element.

Plastic Anchor Recess: Ideal for single-use or limited-cycle projects, our plastic variants offer a lightweight and economical alternative. Despite their cost-efficiency, they maintain high dimensional stability under the pressure of wet concrete.

Steel and Magnetic Anchor Recess: For high-precision industrial applications, our steel formers provide unmatched longevity. When integrated with high-strength magnets, they securely attach to steel formwork without the need for drilling, significantly accelerating production cycles.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Anchor Recess with Shorter Lead Times:

Choosing the right anchor recess is a crucial step in ensuring the safety and efficiency of precast concrete component hoisting. As a precast component expert at HULK Metal, I recommend a professional selection based on the following four dimensions:

1. Matching the Anchor System

This is the most basic and important selection criterion. The anchor recess must be perfectly matched to the type and load group of the anchors used.

Lifting Pin Anchor: A spherical recess former must be selected to create a hemispherical space that allows the lifting anchor to penetrate deeply and engage.

Spread Anchor: A dedicated groove mold must be used; otherwise, the lifting ring will not be installed correctly.

Threaded Socket: Typically used with plastic or magnetic retaining discs to prevent concrete slurry from entering the threads.

2. Select Material Based on Reuse Frequency

HULK Metal manufactures Recess Formers in a variety of materials in its ISO 9001 certified factory to meet different cost and efficiency requirements:

Rubber: Excellent elasticity and durability, reusable multiple times. Its flexibility makes it less likely to damage concrete edges during demolding and easier to remove from cured concrete.

Plastic: Lower cost, typically used for single or limited-use projects. Although consumable, it is essential to ensure its shape stability under concrete pouring pressure.

Steel/Magnetic: Designed specifically for steel formwork. Magnetic Recess can be directly attached to the formwork without drilling, significantly shortening production cycles and reducing damage to the formwork.

3. Consider Working Conditions and Load Requirements

Load Rating: The formwork must be compatible with the corresponding SWL rating (1.3t, 2.5t, 5.0t, etc.). HULK Metal's design ensures that components between different load groups cannot be miscoupled, thus eliminating safety hazards.

Component Thickness: For thin-walled components, a Recess Former that can tightly fit with additional stiffeners (such as Angled Pull Reinforcement) must be selected to ensure that the load is safely transferred to the concrete.

4. Quality Certification and Delivery Standards

Compliance: Products with CE certification must be selected to comply with international lifting safety standards.

Pass Rate: Leveraging HULK Metal's integrated supply chain, we ensure a 99.8% pass rate for our products and provide comprehensive return and exchange services.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Anchor Recess with Better Service:

24/7 Service:

Our dedicated support team is available around the clock to respond quickly to inquiries, provide technical guidance, and ensure smooth communication throughout ordering, production, and delivery stages.

Quality Assurance Services:

Each product undergoes strict inspections, material verification, and dimensional checks to meet international standards, ensuring consistent performance, safety, and reliability in precast concrete applications.

After-sales Service:

We offer responsive after-sales support, including technical assistance, replacement solutions, and problem resolution, ensuring long-term customer satisfaction and reliable project execution.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable Anchor Recess:

Higher Quality Anchor Recess:

Manufactured with precise molds and durable materials, our anchor recesses ensure accurate positioning, reliable anchor engagement, and consistent performance in demanding precast concrete lifting applications.

All-round Cost Control:

Optimized material sourcing, efficient production processes, and stable supply chains help reduce overall costs while maintaining consistent quality and on-time delivery for large or custom orders.

Shaping Your Brand Image:

Consistent product quality, professional packaging, and reliable service support your brand reputation, helping you deliver dependable precast solutions that build long-term customer trust.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Concrete Accessories You Might Want to Know

Besides Anchor Recesses , we also offer Spherical Head Lifting Anchors, and Lifting Clutch For Concrete. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Anchor Recess For Lifting Anchors in Blogs

Here is the introduction, production, and quality inspection of Recess Formers For Lifting Anchors that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a message if you want to share or get some content about Recess Formers For Lifting Anchors.

-

August 20, 2025Selecting the Right Lifting Accessory for Different Precast Applications

August 20, 2025Selecting the Right Lifting Accessory for Different Precast ApplicationsThe efficiency and safety of precast concrete installation depend not only on the precision of the concrete elements themselves but also on the lifting systems used to handle them. Every precast unit—whether it is a wall panel, a structural beam, or a compact architectural detail—requires the correct lifting accessory to ensure secure handling and minimize risks during transport and installation.

-

July 17, 2025Boost Your Precast Productivity with High-Quality Rubber Recess Formers

July 17, 2025Boost Your Precast Productivity with High-Quality Rubber Recess FormersIn the fast-paced world of modern construction, precast concrete components are central to efficient project execution. From wall panels to columns, stairs to beams, the demand for precision, repeatability, and speed in production has never been higher.

-

June 19, 2025How Efficient Precast Accessories Improve Construction Productivity?

June 19, 2025How Efficient Precast Accessories Improve Construction Productivity?In the constantly evolving construction industry, efficiency is more than a goal—it is a necessity. With the growing demand for shorter project timelines, reduced costs, and superior build quality, efficient precast accessories have emerged as essential elements in modern construction workflows.

-

June 04, 2025Application Environment For Precast Concrete Accessories

June 04, 2025Application Environment For Precast Concrete AccessoriesPrecast concrete accessories play a critical role in ensuring the structural integrity, safety, and efficiency of precast elements from fabrication to installation. As precast construction continues to gain popularity for its quality control, speed of assembly, and cost-effectiveness, selecting the appropriate accessories becomes paramount.

Reviews

-

Kojir Taira

I appreciate the precise fit and consistent quality of these anchor recesses, which improved lifting safety and efficiency on site.