Cast In Channel Halfen Anchor Channels

Description:

Cast-in channels, such as the Halfen channel, represent the latest in high-end building materials, designed for ease of installation and adjustable connections. Each channel features a full foam filler to prevent concrete ingress, ensuring a clean and precise installation. Utilizing advanced cold riveting techniques, our cast-in channels are engineered for reliable and enduring load capacity. We provide high-quality cast-in channels, available in both hot-rolled and cold-rolled varieties. Our semi-automatic production process for hot-forged T-bolts complements our comprehensive range of cast-in channel systems. Cast-in channels are versatile and suitable for a wide array of applications, including tunnels, subways, bridges, airports, nuclear power stations, environmental projects, facades, stadiums, and opera houses.

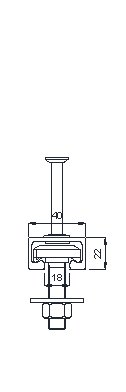

Dimensions and Tolerances of Cast-in Channels

Dimensions and Tolerances of the HM Cast in Channel | ||||||||||

|

|

|

|

|

|

|

|

| ||

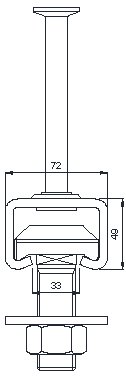

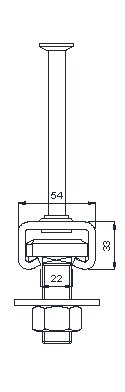

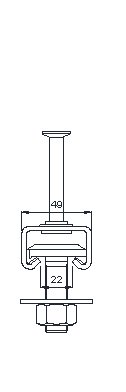

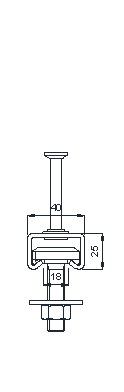

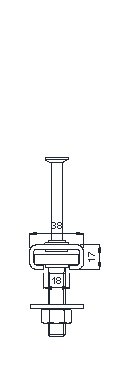

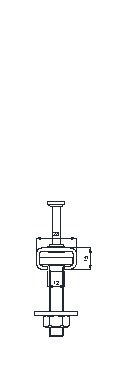

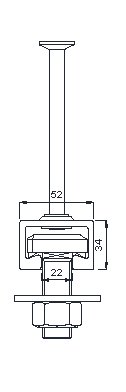

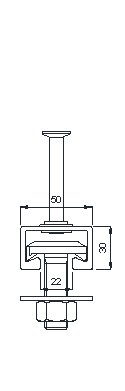

HM- 7249 | HM- 5433 | HM- 4930 | HM- 4025 | HM- 3817 | HM- 2815 | HM- 5234 | HM- 5030 | HM- 4022 | HM- 4122 | |

Channel Section(mm) | ||||||||||

72/49 | 54/33 | 49/30 | 40/25 | 38/17 | 28/15 | 52/34 | 50/30 | 40/22 | 41/22 | |

T.Bolt min spacing (mm) | ||||||||||

121 | 80 | 74 | 64 | 47 | 41 | 81 | 73 | 58 | 28 | |

T.Bolt Size | ||||||||||

M20/ 24/30 | M12/ 16/20 | M12/ 16/20 | M10/ 12/16 | M10/ 12/16 | M8/ 10/12 | M20/ 24/30 | M12 16/20 | M12/ 16/20 | M12/16 | |

Design Resistance Capacities of Profiles (Design values)(KN) | ||||||||||

45 | 41.6 | 17.2 | 12.2 | 10.6 | 7.2 | 30.6 | 17.2 | 11.1 | 15.8 | |

Materials | Q235B / Stainless Steel / Customized | |||||||||

Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized | |||||||||

Service | Freight consulting / Quality inspection / After Service / Other value-added services. | |||||||||

Delivery Method | Sea / Air / Land | |||||||||

Features of Cast In Channel:

-

Design Principles of Cast In Channel:

The Cast-in Channel is a specialized embedded component widely utilized in construction projects for secure and efficient installations. This pre-embedded equipment involves initially embedding the C-shaped trough into the concrete structure. Once the trough is securely in place, the T-shaped bolts are then inserted, with the large head of the T-shaped bolt fitting snugly into the C-shaped trough. This configuration ensures a robust and reliable anchorage system.

The primary advantage of using the Cast-in Channel system lies in its ability to provide a flexible and adjustable fixing method. Embedding the C-shaped trough in the concrete, it allows for precise adjustments and positioning of the components to be installed. The T-shaped bolts are then used to securely fasten the components to the concrete structure via the pre-embedded C-shaped trough. This method not only enhances the stability and durability of the installation but also significantly reduces the time and labor required for on-site adjustments and modifications.

Furthermore, the Cast-in Channel system is highly versatile and can accommodate a wide range of construction applications. It is particularly beneficial in scenarios where high precision and load-bearing capacities are critical. By using the T-shaped bolt fixation within the C-shaped trough, engineers and construction professionals can achieve optimal results with enhanced safety and efficiency.

Overall, the Halfen trough system represents a modern and innovative solution for embedding components in concrete, providing a reliable, adjustable, and time-efficient method for construction projects.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

The Advantage of Cast In Channel:

1. High Loading Capacity and Shearing Force

Our cast-in channels are engineered to provide exceptional loading capacity and shearing force. This ensures that they can support substantial weights and endure significant stress without compromising structural integrity. The robust design of our channels guarantees reliable performance even in demanding applications, making them an ideal choice for various construction projects.

2. Easy Adjustment and Installation, High Efficiency to Save Cost

Our cast-in channels are designed for easy adjustment and installation, significantly enhancing project efficiency and reducing overall costs. The streamlined installation process minimizes labor time and effort, allowing for quicker project completion. By facilitating straightforward adjustments, our channels contribute to a more flexible and efficient construction workflow, ultimately leading to cost savings.

3. Noise-Free, No Drilling Holes, No Powder, Environmental Protection

Our cast-in channels promote an environmentally friendly approach to construction. They eliminate the need for drilling holes, which not only reduces noise pollution but also prevents the production of harmful dust particles. This noise-free and dust-free installation process contributes to a safer and healthier work environment. Additionally, the eco-friendly nature of our products aligns with modern sustainability standards, ensuring minimal environmental impact.

4. Used for Vertical and Horizontal Installation

Versatility is a key feature of our cast-in channels, as they are suitable for both vertical and horizontal installation. This adaptability makes them an excellent choice for a wide range of applications, from supporting structural elements in buildings to securing various fixtures and fittings. The ability to install our channels in multiple orientations enhances their utility and simplifies the planning and execution of construction projects.

5. High Corrosion Prevention, Adopting Hot Dipped Galvanizing Surface and Stainless Steel Surface

To ensure long-lasting durability, our cast-in channels are manufactured with high corrosion prevention measures. We employ hot-dipped galvanizing and stainless steel surfaces to protect against rust and corrosion, even in harsh environments. This robust corrosion resistance ensures the longevity and reliability of our products, making them a cost-effective investment for any construction project.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Cast In Channel For Better Service:

Dedicated and Professional Customer Service Team

To better serve our customers, we have established a dedicated service team. Our team provides comprehensive support, including free technical assistance, raw material procurement, production tracking, quality inspection, packaging design, and freight consulting, tailored to your specific needs.

24/7 Service

Our team is available 18 hours a day, 7 days a week. You can reach out to us at any time with your inquiries. We are committed to providing prompt and effective solutions.

Order Tracking and Feedback

We ensure continuous follow-up on your order's production, offering feedback through detailed pictures and videos. Additionally, we provide the option for you to participate in real-time production monitoring of Tubular Lifting Sockets via video calls.

Quality Assurance Service

Quality assurance is a fundamental aspect of our service. You can purchase, sell, or use our cast-in channel with complete confidence.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable Cast In Channel:

Superior Quality and Cost Management

We ensure the production costs of your order align with your requirements without compromising the quality of our cast-in channels. Our robust production and service capabilities enable us to achieve this balance effectively.

Holistic Cost Control

Leveraging our comprehensive supply chain, we optimize every aspect of the process to control costs efficiently. This allows you to spend less time on supplier selection, procure more cost-effective cast-in channels, and receive your goods faster, all while maintaining the high quality you expect.

Enhancing Your Brand Image

Our commitment to providing higher standard cast-in channels, expedited delivery, and exceptional service support contributes significantly to strengthening your brand image.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Concrete Accessories You Might Want to Know

Besides Cast In Channels, we also provide Lifting Clutch, Spread Anchors, Spherical Head Lifting Anchors, Lifting Sockets, and Recess Formers. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Cast In Channel in Blogs

Here is the introduction, production, and quality inspection of the Cast In Channel that we can organize, as well as some sharing from customers and details of our delivery. You can message us to share or get some content about cast in channel.

Reviews

-

Diego Nanini

Earnest is very responsive. The product delivered on time and received in good condition.