Precast Ferrules

Description:

HULK Metal offers a comprehensive range of precast ferrules designed to deliver secure and reliable solutions for precast concrete applications. Our standard precast ferrules are available in thread sizes from M12 to M52, with overall lengths ranging from 30 mm up to 620 mm, ensuring compatibility with a wide variety of structural and lifting requirements. Manufactured from high-quality steel and produced under strict quality control, each ferrule provides excellent load-bearing capacity, precise threading, and consistent performance in demanding construction environments. In addition to our standard range, HULK Metal specializes in custom precast ferrules, engineered to match specific drawings, load ratings, surface treatments, and project standards.

Parameters of HULK Metal Precast Ferrules:

| Product | What it is | How it works |

|---|---|---|

| Flat End Lifting Insert | A threaded steel insert with a flat end, designed for embedding in precast concrete. | Provides a secure threaded connection for lifting accessories; the flat end ensures stable anchoring within concrete. |

| Solid Rod Lifting & Fixing Socket | A heavy-duty socket made from a solid steel rod with internal threads. | Embedded in concrete to create a strong lifting or fixing point, it transmits loads directly through the solid rod body. |

| Combi Lifting Socket | A versatile socket combining lifting and fixing functions. | Works as both a lifting insert and a structural fixing point, reducing the need for multiple components. |

| Tubular Lifting Insert | A hollow steel tube insert with internal threading. | Lightweight yet strong, the tubular design allows efficient anchoring for lifting loops or bolts in precast elements. |

| Wavy Tail Lifting Insert | A threaded insert with a wavy tail extension. | The wavy tail increases bond strength by interlocking with concrete, ensuring secure load transfer during lifting. |

| Crown Foot Lifting Anchor | A forged steel anchor with a crown-shaped base. | The crown foot spreads the load within the concrete, preventing pull-out and allowing safe lifting at various angles. |

| Bolt Anchor Lifting Sockets | A socket designed for flat precast elements such as slabs or panels. | Installed flush with the surface; bolts are connected for lifting, ensuring reliable handling during transport and installation. |

Features of Precast Ferrules:

-

Higher Quality Precast Ferrules:

What Are Precast Ferrules?

Precast ferrules are cast-in threaded inserts embedded in precast concrete elements to provide secure fixing points. They enable safe lifting, fastening, and assembly of panels, beams, and structural components, ensuring accurate alignment, high load capacity, and efficient on-site installation.

Introduction

MATERIAL:Stainless Steel / Q345 / Q235 / 20# / Customizable

SURFACE TREATMENT:Raw Color, Electro-galvanized, Hot-dip Galvanized

SAFETY FACTOR:≥ 3

CERTIFICATE:CE / ISO 9001

Production Process of Precast Ferrules

Raw Material Control

All raw materials are sourced from stable, long-term partner suppliers. Each incoming batch is accompanied by full material certificates, which are carefully recorded and archived to ensure complete traceability throughout production.

Cutting and Pre-Processing

Approved materials are cut into precise dimensions in accordance with engineering drawings. Random sampling inspections are conducted at this stage to verify dimensional accuracy and ensure readiness for subsequent operations.

Forming and Machining

Different precast ferrule designs require specific manufacturing methods. Flat-end inserts are produced through pressing, punching, and threading steel tubes. Solid rod inserts are drilled on one side and threaded on the other. Tubular inserts are drilled and tapped, while wavy and combi inserts involve bending reinforcement or solid rods before threading. Flat plate inserts are welded to steel plates, and bolt anchor inserts are assembled with anti-rotation features formed using dedicated tooling.

Surface Protection

Stainless steel ferrules are supplied without coating. Carbon steel ferrules receive oil coating, hot-dip galvanizing, or electro-galvanizing to enhance corrosion resistance.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Precast Precast Ferrules With Shorter Lead Time:

Flat End Precast Ferrules

Used for general fixing and lifting points in precast concrete panels. The flat end ensures stable load transfer and reliable anchorage when cast flush into concrete elements.

Solid Rod Precast Ferrules

Designed for high-load applications where superior tensile strength is required. Commonly used in structural connections, they provide excellent pull-out resistance and precise threaded engagement.

Tubular Precast Ferrules

Ideal for lightweight to medium-duty fixings in precast components. The hollow structure reduces material weight while maintaining adequate load capacity for assembly and installation purposes.

Wavy Precast Ferrules

Primarily used in applications requiring enhanced bond strength with concrete. The wavy reinforcement profile improves mechanical interlock, minimizing rotation and increasing anchorage performance.

Combi Precast Ferrules

Applied in heavy-duty precast connections combining high tensile loads and strong concrete bonding. The solid rod with anchoring features ensures superior load distribution and anti-rotation stability.

Flat Plate Precast Ferrules

Commonly used where surface load distribution is critical. The welded plate increases bearing area, reduces concrete stress, and provides secure fixing points in thin precast elements.

Bolt Anchor Precast Ferrules

Used for temporary or permanent fixing applications requiring anti-rotation performance. Integrated bolt design ensures reliable load transfer and easy installation during precast assembly.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Precast Ferrules with Better Service:

High-Quality Precast Ferrules:

HULK Metal produces high-quality precast ferrules using premium raw materials and advanced manufacturing techniques, ensuring durability, precise dimensions, and reliable performance in concrete construction applications.

Quality Inspection Services:

Every product undergoes rigorous quality inspection with state-of-the-art equipment to verify compliance with international standards, guaranteeing consistent quality before shipment to bulk buyers.

After-Sales Service:

HULK Metal offers after-sales support for products with verified quality issues, providing timely solutions to ensure customer satisfaction and project continuity.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable Precast Ferrules:

Competitive Pricing:

HULK Metal offers competitive pricing by optimizing production efficiency and leveraging long-term supplier partnerships to deliver cost-effective solutions for bulk buyers without compromising quality.

Comprehensive Cost Control:

Through integrated supply chain management, in-house logistics, and efficient manufacturing processes, HULK Metal maintains strict control over all cost elements from raw materials to delivery.

Build Your Brand Image:

By supplying reliable, high-quality precast concrete accessories and offering OEM services, HULK Metal helps partners strengthen their market reputation and enhance brand credibility globally.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Lifting Thread Inserts You Might Want to Know

Discover Fixing Sockets with Bent End, Bolt Anchor Lifting Sockets with Cross Pins, and Flat Fixing Sockets with Cross Pin. Click the images for details. With a comprehensive production range, trust us for your orders.

You Can Know About Precast Lifting Thread Inserts in Blogs

Discover our organized insights into precast lifting thread inserts – from introduction, production, and quality checks, to customer testimonials and delivery specifics. Reach out to us for more content or to share your thoughts on these exceptional products.

-

August 20, 2025Selecting the Right Lifting Accessory for Different Precast Applications

August 20, 2025Selecting the Right Lifting Accessory for Different Precast ApplicationsThe efficiency and safety of precast concrete installation depend not only on the precision of the concrete elements themselves but also on the lifting systems used to handle them. Every precast unit—whether it is a wall panel, a structural beam, or a compact architectural detail—requires the correct lifting accessory to ensure secure handling and minimize risks during transport and installation.

-

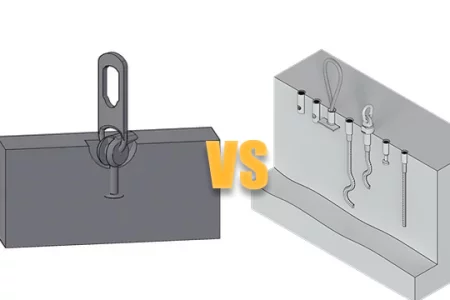

June 20, 2025Lifting Sockets vs Lifting Anchors: Which Is Better for Precast Concrete?

June 20, 2025Lifting Sockets vs Lifting Anchors: Which Is Better for Precast Concrete?Precast concrete has become one of the key materials in modern construction. Whether you are working on large infrastructure projects or building residential developments, using precast concrete components can significantly improve efficiency, consistency, and safety on-site.

-

March 04, 2025How to use Lifting Loop correctly for safe lifting of concrete components

March 04, 2025How to use Lifting Loop correctly for safe lifting of concrete componentsIn modern construction and precast concrete industry, safe and efficient lifting operations are essential. As a system specially used for lifting and handling concrete products, Lifting Loop is widely used in the movement and installation of precast components, pipes, wall panels and other large concrete products. Its embedded design enables it to withstand high-intensity tension, while simplifying the lifting process and improving construction efficiency.

-

February 13, 2025Comprehensive introduction and application of Lifting Socket

February 13, 2025Comprehensive introduction and application of Lifting SocketIn the construction industry, lifting operations are a vital link, especially when it comes to heavy precast concrete structures. Lifting Sockets, as an indispensable part of lifting operations, plays a vital role. They are often used to connect lifting equipment to precast concrete components, steel structures, or other building components to ensure the safety and efficiency of the lifting process.

Reviews

-

Micah Hudson

Excellent precast ferrules with precise threads and consistent quality, providing strong anchorage, easy installation, and reliable performance in demanding precast concrete projects.