Short Wavy Lifting Insert

Description:

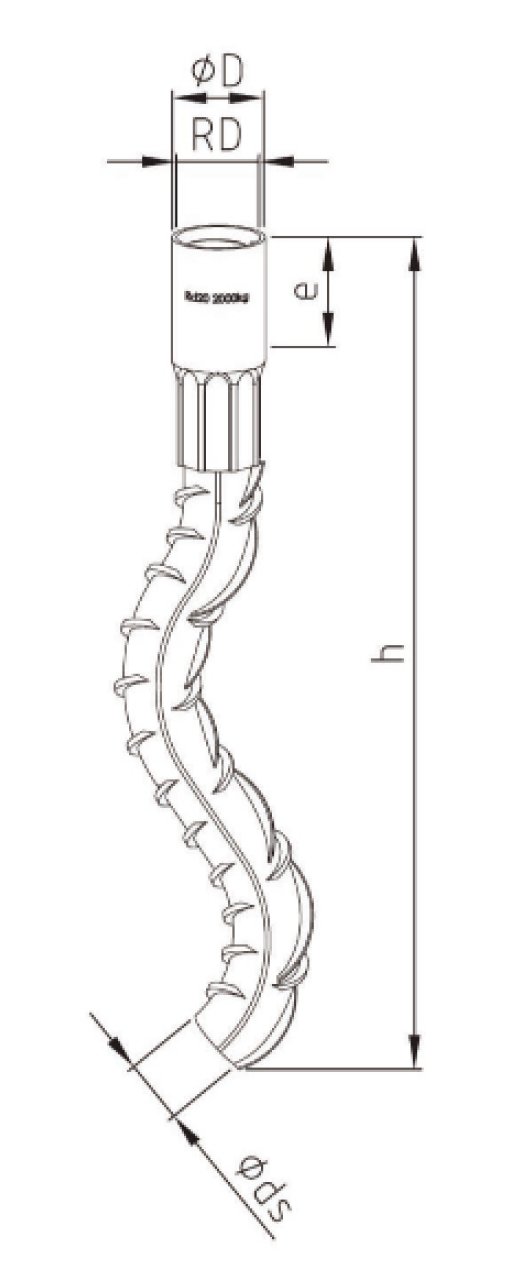

The Short Wavy Lifting Insert is a compact, high-performance lifting solution designed specifically for precast concrete handling applications. This lifting insert features a unique wavy steel tail design that enhances its mechanical anchorage within the concrete, ensuring uniform load distribution and reducing localized stresses that could lead to cracking. Constructed from high-strength carbon steel and manufactured under stringent quality control, it delivers reliable performance even under demanding lifting conditions. Its short profile makes it ideal for thin or space-constrained precast components while maintaining excellent load-bearing capacity.

Parameters of HULK Metal Short Wavy Lifting Sockets:

| NAME | MATERIAL | Stainless Steel / Q345 / Q235 / 20# / Customizable | |||||

| Short Wavy Lifting Insert | SURFACE TREATMENT | Raw Color, Electro-galvanized, Hot-dip Galvanized | |||||

| SAFETY FACTOR | ≥ 3 | ||||||

| CERTIFICATE | CE / ISO 9001 | ||||||

| SWL (tons) | CODE | THREAD(RD/M) | H(mm) | D(mm) | E(mm) | DS(mm) | |

| 0.5 | SWS-M/RD12-105 | 12 | 105 | 15 | 22 | 8 |

| 1.2 | SWS-M/RD16-165 | 16 | 165 | 21 | 27 | 12 | |

| 2.0 | SWS-M/RD20-195 | 20 | 195 | 27 | 35 | 14 | |

| 2.5 | SWS-M/RD24-240 | 24 | 240 | 31 | 43 | 16 | |

| 4.0 | SWS-M/RD30-300 | 30 | 300 | 40 | 56 | 20 | |

| 6.3 | SWS-M/RD36-380 | 36 | 380 | 47 | 68 | 25 | |

| 8.0 | SWS-M/RD42-450 | 42 | 450 | 54 | 80 | 28 | |

Features About HULK Metal Short Wavy Lifting Insert:

-

Higher Quality Short Wavy Lifting Insert:

What is Short Wavy Lifting Insert?

A Short Wavy Lifting Insert is a specialized lifting component used in precast concrete applications to provide safe and reliable handling of concrete elements. It consists of a high-grade zinc-plated carbon steel socket securely swaged to a wavy reinforcement bar, ensuring strong anchorage and effective load transfer within the concrete. Available with Rd12 to Rd42 threads, these inserts offer load capacities ranging from 500 kg to 8000 kg. For projects requiring enhanced corrosion resistance, stainless steel sockets and rebar tails can be supplied upon request.

Introduce

Material:Stainless Steel / Q345 / Q235 / 20# / Customizable

Surface Treatment: Raw Color, Electro-galvanized, Hot-dip Galvanized

CE, ISO 9001 Short Wavy Lifting Insert

3 Times Safety Factor

Features

1 Shorter Production Cycle

2 Deliver Faster

3 Comprehensive After Service

Application

Short Wavy Lifting Inserts are widely applied in the handling of thin precast concrete elements, including slim wall panels, flat slabs, and architectural façade components. Their compact design makes them especially effective for prefabricated masonry walls where embedment depth is limited.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Short Wavy Lifting Insert with Shorter Lead Time:

The optimal lifting method is depicted below, with a lifting angle of β ≤ 30° .

Materials: Stainless Steel / Q345 / Q235 / 20#

The safe working loads indicated are calculated after applying a safety factor of 2 for 15 N/mm2

concrete and 3 for steel.

Minimum er assumes that the reinforcement

cover is satisfactory to the designer: stainless steel

might be necessary if the cover is restricted.

Lifting on site is usually the worst case due to

higher crane factors and a worse angle of lift (β).

F = [G + (q × A) × f × Z] / n

Site – handling

F = G × f × Z / n

i.e. factors f and Z are

usually worse on site

F = load per insert when lifting

G = dead weight of unit

Q×A = adhesion to the mould

f = crane factor

Z = factor for angle β

n = number of inserts

Production Process of Short Wavy Lifting Inserts

Raw Material Preparation

High-quality steel pipes and reinforcement bars are selected and cut to exact lengths to ensure dimensional accuracy and consistent mechanical performance.

Wavy Rebar Forming

The rebars are precisely bent into a controlled wavy shape, which improves anchorage within concrete and enhances load distribution during lifting.

Thread Machining

Steel pipes are internally tapped to produce accurate M/Rd threads.

Surface Treatment

The threaded pipes undergo zinc plating or other specified surface treatments to increase corrosion resistance and extend service life.

Swaging and Assembly

The treated pipes are mechanically swaged onto the straight ends of the wavy rebars, creating a strong and reliable connection.

Quality Inspection and Testing

Each lifting insert is inspected for thread accuracy, dimensional tolerance, and load capacity before packaging to guarantee safe and dependable performance.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Short Wavy Lifting Insert with Better Service:

24/7 Service:

Our professional support team provides round-the-clock assistance for Short Wavy Lifting Insert selection, technical inquiries, and order coordination, ensuring timely responses and smooth communication across all project stages.

Packaging and Freight Services:

Short Wavy Lifting Inserts are securely packed using export-standard materials, with flexible logistics solutions, optimized loading plans, and reliable shipping methods to ensure safe, on-time global delivery.

Quality Assurance Service:

Each Short Wavy Lifting Insert undergoes strict quality control, including material verification, dimensional inspection, thread accuracy checks, and load testing, guaranteeing compliance with international precast lifting standards.

After-sales Service:

We offer responsive after-sales support for Short Wavy Lifting Inserts, providing technical guidance, quality feedback handling, and replacement solutions to ensure long-term reliability and customer satisfaction.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable Short Wavy Lifting Insert:

Higher Quality Short Wavy Lifting Insert:

Each Short Wavy Lifting Insert is produced from carefully selected steel, precisely manufactured, and thoroughly tested to deliver stable lifting performance, strong anchorage, and long service life in precast concrete applications.

Comprehensive Cost Control:

Optimized production planning, efficient material usage, and streamlined processes help reduce overall costs while maintaining reliable quality, allowing customers to achieve better value with safety or performance.

Shaping Your Brand Image:

Consistent product quality, professional packaging, and dependable service support help reinforce your brand’s credibility, enabling you to present reliable lifting solutions that build trust with contractors and project owners.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Lifting Insert You Might Want to Know

Besides Short Wavy Lifting inserts, we also offer Tubular Lifting Sockets, Flat End Lifting Sockets, Lifting Loops, Solid Rod Lifting Sockets, and other lifting sockets. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Lifting Insert in Blogs

Here is the introduction, production, and quality inspection of Long Wavy Lifting Sockets that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a message if you want to share or get some content about Long Wavy Lifting Sockets.

-

February 28, 2025How to use Wavy Tail Anchor to improve construction efficiency and safety

February 28, 2025How to use Wavy Tail Anchor to improve construction efficiency and safetyIn the construction industry, shuttering magnets have become one of the key tools to improve construction efficiency and safety. They are widely used in the production of precast concrete to firmly fix the formwork and ensure accuracy and stability during the concrete pouring process.

-

January 13, 2025Quality control of precast concrete accessories

January 13, 2025Quality control of precast concrete accessoriesIn the construction industry, precast concrete accessories, as an important element of the project, are responsible for ensuring structural safety, construction efficiency, and long-term performance. The quality of accessories directly affects the quality and stability of the entire construction project.

-

December 17, 2024Why should every manufacturer conduct tensile testing?

December 17, 2024Why should every manufacturer conduct tensile testing?Tensile testing is an indispensable part of modern manufacturing. It is not only a technical means to test product performance, but also an important cornerstone for enhancing brand reputation and ensuring product safety.

-

July 02, 2024Lifting Socket: Types and Selection Guide

July 02, 2024Lifting Socket: Types and Selection GuideIn the lifting and installation process of precast concrete elements, lifting sockets play a crucial role. They ensure the safety and stability of elements during lifting and installation, while also improving construction efficiency. As a professional manufacturer of precast concrete accessories, we offer various types of lifting sockets to meet different engineering needs.

Reviews

-

Leo Ceja

I have purchased Short Wavy Lifting Inserts from HULK Metal multiple times; the quality is reliable, and I will continue to repurchase.