Connection Loop Boxes

Description:

Connection Loop Boxes are a reliable solution for creating secure and efficient joints between precast concrete units and in-situ concrete structures. Designed with a durable steel casing,each box contains flexible wire loops that can be easily released using no-tool tear-off tape, ensuring simple and fast installation. Once exposed, the loops are anchored into adjoining concrete elements with reinforcing bars and in-situ concrete, delivering a strong and safe structural connection. With their ease of use, high load-bearing capacity, and consistent performance, Connection Loop Boxes are widely applied in modern construction projects, ensuring precision, safety, and long-term reliability in precast connections.

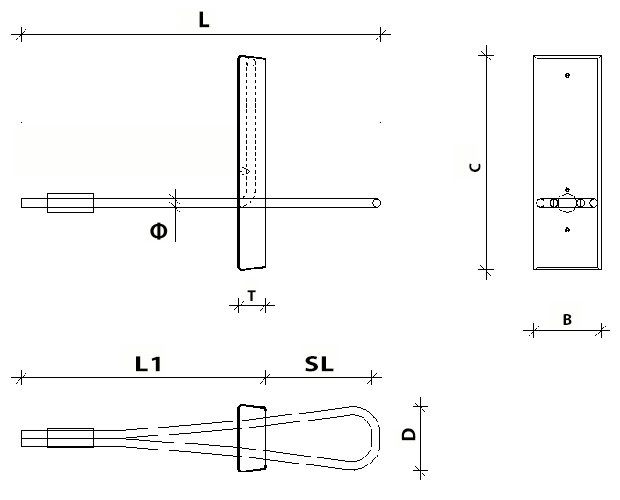

Dimensions and Tolerances of HULK Metal Connection Loop Boxes

| NAME | HULK Metal Wire Loop Box | ||||||||

| DRAWINGS | Types | SL [mm]±10 | L1 [mm]±10 | L [mm]±20 | C [mm]±2 | D [mm] | B [mm]±2 | T [mm]±2 | Φ [mm] |

| HM-A | 60 | 210 | 276 | 160 | 60 | 50 | 20 | 6 |

HM-B | 80 | 210 | 296 | 160 | 60 | 50 | 20 | 6 | |

HM-C | 100 | 210 | 316 | 160 | 65 | 50 | 20 | 6 | |

HM-D | 120 | 210 | 336 | 160 | 70 | 50 | 20 | 6 | |

HM-E | 140 | 370 | 528 | 200 | 100 | 70 | 30 | 8 | |

Thickness of the Steel Plate of the Box | |||||||||

0.5~0.7mm | |||||||||

Materials of the Wire Loop Box | |||||||||

Compression Sleeve | 1.0330 | ||||||||

Wire Loop | high-strength steel wire rope SE-Zn | ||||||||

Box | 1.0046 | ||||||||

Packaging | Wooden case / Carton / Bulk / Individually Packaged / Customized | ||||||||

Service | Freight consulting / Quality inspection / After-sales / Other value-added services. | ||||||||

Delivery Method | Sea / Air / Land | ||||||||

Quality Assurance | Life-Long | ||||||||

Features of HULK Metal Connection Loop Boxes:

-

Design Principles of HULK Metal Connection Loop Boxes:

Component Breakdown

The Connection loop box is composed of three key parts:

Compression Sleeve (20# Steel)

Crafted from high-quality 20# steel, the compression sleeve delivers outstanding strength and durability. Its precise design keeps the wire loop securely in place, ensuring long-term stability and dependable performance, even under heavy loads in concrete connections.

Wire Loop (High-Strength SE-Zn Steel Wire Rope)

The wire loop is made from SE-Zn coated high-strength steel wire rope, offering excellent tensile strength and corrosion resistance. This guarantees safe and efficient load transfer between concrete elements, while maintaining flexibility and reliability in both indoor and outdoor applications.

Box (Galvanized Steel Sheet)

Manufactured from premium galvanized sheet steel, the box provides superior resistance to rust and environmental impact. It effectively protects the embedded wire loop while maintaining precise dimensions for smooth integration into precast concrete components during manufacturing and installation.

How Connection Loop Boxes Work

Connection Loop Boxes are designed to create strong and reliable joints in precast construction through a simple and efficient process:

1. Integration During Production

A steel box with wire loops is embedded directly into the precast concrete element during manufacturing.

2. Safe Storage

The loops remain neatly protected inside the box with a cover, ensuring they stay secure until installation.

3. Quick On-Site Activation

When needed, the adhesive tape is removed, and the loops are easily unfolded for connection.

4. Rebar Integration

Reinforcing bars are threaded through the loops, securely linking adjoining elements.

5. Final Bonding

Fresh concrete is poured, creating a strong, monolithic connection with excellent stability and load-bearing capacity.

This method simplifies installation, saves time on site, and guarantees long-term structural integrity for modern construction projects.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Installation of HULK Metal Connection Loop Boxes:

Case 1 – Where wire loops are used to transfer forces

When HM wire loop boxes are used to transfer forces in the joint, the anchorage of the wire loop box must be secured by overlapping the wire loop box sufficiently with the reinforcement of the concrete element. This should be done according to the engineer’s design, depending on your precise arrangement. Where the wire loop is used in a corner joint, a reinforcing bar should be installed into the inner edge of the fold of the HM wire loop box; the diameter of this bar should be the same as the reinforcement installed in the joint.

Case 2 – Where HM wire loops are not used to transfer forces

When wire loops boxes are used to limit cracking of the seam or to tie elements together without establishing the required force, additional reinforcement in the wall is recommended, as shown here, including 2 additional 10mm diameter bars in each piece.

Attachment to the formwork:

The wire rope loop box must be securely attached so it cannot be moved during concrete casting. The concrete must be compacted carefully to prevent vibration. The wire rope loop boxes may be fastened to the formwork with nails or magnets.

The portion of the wire rope that enters the concrete element is installed adjacent to the reinforcement and does not need to be tied to the reinforcement.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

HULK Metal Connection Loop Boxes with Better Service:

Quality Inspection Services

HULK Metal's connection loop boxes are CE-certified and undergo testing before shipment, including material testing, tensile testing, and dimensional accuracy inspections to ensure they meet safety requirements.

Packaging Services

HULK Metal uses high-quality materials, such as fumigated wooden crates, reinforced pallets, steel strapping, and moisture-proof film, to ensure every order arrives intact. Each package is customized based on product size, weight, and handling requirements, ensuring space-saving, stable, and cost-effective loading.

Freight Services

HULK Metal has a comprehensive in-house freight system, providing customers with safe, efficient, and stable transportation solutions. We can flexibly arrange various modes of transportation, including sea, land, and air, based on the quantity, volume, and delivery time of customer orders. This not only gives us significant advantages in terms of timeliness, transportation costs, and cargo safety, but also helps customers reduce communication and waiting time at intermediate locations.

After-Sales Service

HULK Metal is committed to building long-term partnerships with our customers and ensuring the reliable delivery of every order. If you have any questions during the use of the product, you can contact us at any time and we will provide you with professional technical support.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable HULK Metal Connection Loop Boxes:

Optimized Material Usage

Designed with high-strength steel wire loops and durable galvanized casings, these connection loop boxes ensure maximum performance while minimizing unnecessary material waste, effectively lowering overall production costs.

Reduced Labor and Installation Time

With easy on-site activation and no additional formwork required, installation is simplified. This shortens assembly time, reduces labor costs, and improves project efficiency.

Reliable Long-Term Investment

Connection loop box's strong structural bonding and corrosion resistance minimize maintenance needs and repair costs, delivering dependable connections and long-term savings across construction projects.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Concrete Accessories You Might Want to Know

Besides connection loop boxes, we also provide Lifting Clutch, Spread Anchors, Spherical Head Lifting Anchors, Lifting Sockets, and Recess Formers. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Connection Loop Boxes in Blogs

Here is the introduction, production, and quality inspection of the connection loop box that we can organize, as well as some sharing from customers and details of our delivery. You can message us to share or get some content about connection loop boxes.

-

August 25, 2025Everything You Need to Know About Lifting Loop System

August 25, 2025Everything You Need to Know About Lifting Loop SystemIn modern construction, the demand for safe, efficient, and flexible lifting solutions has grown significantly, especially with the increasing use of precast concrete elements. Large concrete slabs, beams, and slabs cannot be handled manually; they require robust lifting systems to ensure safety and efficiency on site.

-

August 19, 2025Everything You Need to Know About Spread Anchor System

August 19, 2025Everything You Need to Know About Spread Anchor SystemIn today's precast construction industry, speed, safety, and precision are non-negotiable requirements. From concrete pouring to lifting and installation, every stage must be optimized to ensure projects are completed on time and within budget.

-

August 12, 2025Everything You Need to Know About Lifting Anchor Systems

August 12, 2025Everything You Need to Know About Lifting Anchor SystemsIn the precast concrete industry, details determine success or failure—especially when it comes to lifting and handling heavy components. Whether installing wall panels, beams, columns, or bridge sections, you need reliable equipment. One of the most important tools is the lifting anchor system.

-

August 06, 2025ISO Certified Precast Concrete Accessories Factory in China

August 06, 2025ISO Certified Precast Concrete Accessories Factory in ChinaWhen it comes to sourcing precast concrete accessories, finding a reliable, high-quality manufacturer is everything. From lifting sockets and wire loop boxes to spread anchors and cast-in channels, your project’s structural integrity depends on the components you choose.

Reviews

-

Michael Thompson

As a project manager, I rely on HULK Metal Connection Loop Boxes for secure, easy-to-install precast connections, ensuring safety, efficiency, and long-lasting structural reliability.