Ring Clutch Lifting Device

Description:

The ring clutch lifting device is a precision-engineered connection system designed to ensure safe, stable, and efficient handling of precast concrete elements. Its structure combines a robust lifting head with a freely rotating shackle, allowing exceptional flexibility during load engagement and orientation. The integrated locking bolt enables quick, secure attachment to compatible lifting anchors, minimizing setup time and enhancing operational safety. Both the lifting head and forged bolt are manufactured from high-strength alloy steel to ensure consistent mechanical properties, superior durability, and reliable performance under demanding load conditions. This design makes the ring clutch an essential tool for modern precast construction environments requiring efficiency, precision, and maximum lifting security.

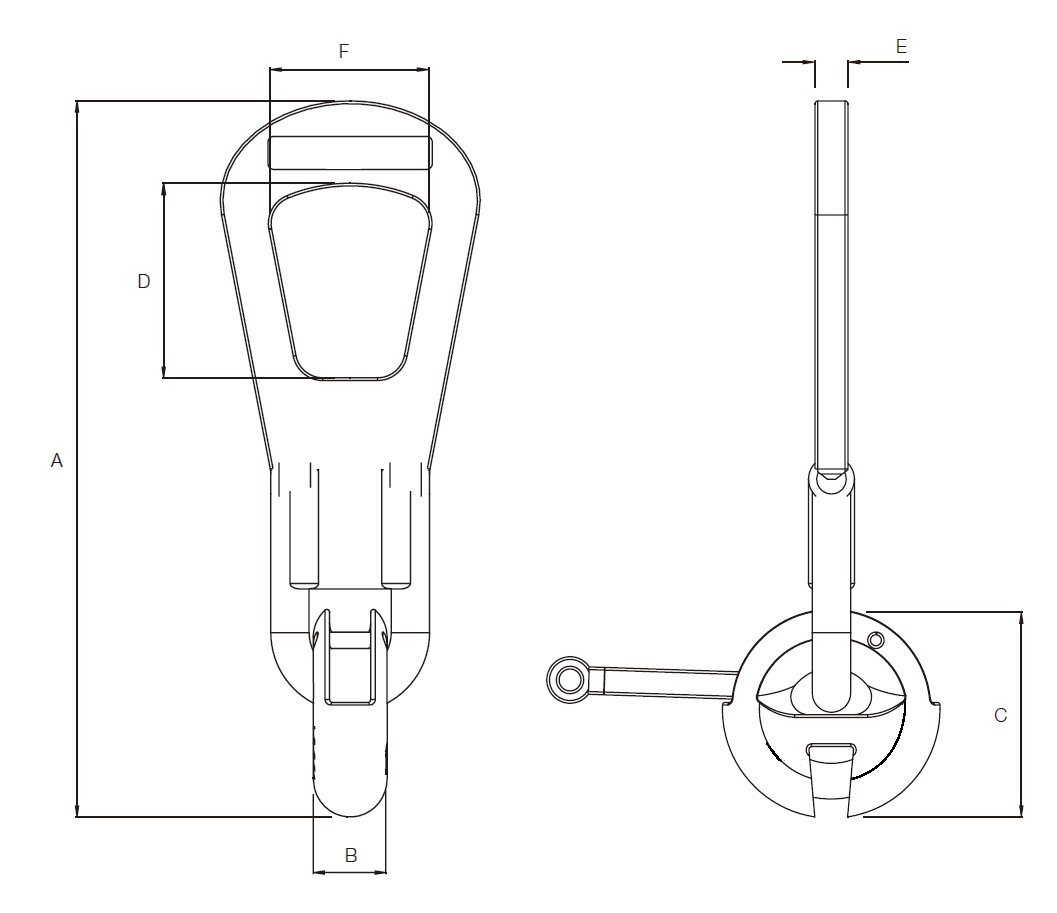

Parameters of HULK Metal Ring Clutch Lifting Device:

| NAME | MATERIAL | Q345D / Q355D / CM490 / G30CrMoV / Customizable | |||||

| HULK Metal Ring Clutch | SURFACE TREATMENT | Electro-galvanized | |||||

| SAFETY FACTOR | ≥ 5 | ||||||

| CERTIFICATE | ISO9001 / CE | ||||||

| SWL (tons) | CODE | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | |

| 2.5 | RC025-261 | 261 | 27 | 80 | 70 | 50 |

| 5.0 | RC050-330 | 330 | 36 | 100 | 86 | 71 | |

| 10.0 | RC100-425 | 425 | 50 | 140 | 112 | 90 | |

| 26.0 | RC260-605 | 605 | 72 | 209 | 160 | 120 | |

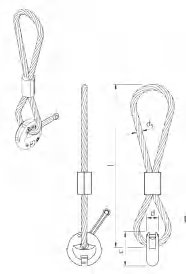

| NAME | MATERIAL | Q345D / Q355D / CM490 / G30CrMoV / Customizable | ||||

| Wire Loop Ring Clutch | SURFACE TREATMENT | Electro-galvanized | ||||

| SAFETY FACTOR | ≥ 5 | ||||

| CERTIFICATE | ISO9001 / CE | |||||

| SWL (tons) | CODE | LENGTH(mm) | C(mm) | D(mm) | DS(mm) | |

| 1.25 | RC0125-20-0320 | 320 | 52 | 20 | dia. 8 | |

| 2.5 | RC0250-27-0560 | 560 | 80 | 27 | dia.14 | |

| 5.0 | RC0500-27-0595 | 595 | 105 | 36 | dia.18 | |

| 10.0 | RC1000-50-0702 | 702 | 150 | 50 | dia.22 | |

| 26.0 | RC2600-72-1570 | 1570 | 206 | 72 | dia.32 | |

Features About Ring Clutch Lifting Device:

-

Higher Quality Ring Clutch Lifting Device:

Ring clutch lifting device description:

The Ring Clutch Lifting Device is a high-performance connection system engineered for the safe and efficient handling of precast concrete components. It features a durable lifting head paired with a freely moving shackle, allowing superior flexibility and smooth load alignment during lifting operations. The integrated locking bolt ensures quick, secure engagement with compatible anchors, while both the bolt and head are forged from high-strength steel for consistent durability. The lifting clutch hook is manufactured with increased thickness and undergoes precise welding verified by X-ray inspection to guarantee structural integrity. Its hardened and tempered cast-steel bail delivers outstanding load resistance. Fully compliant with safety regulations for precast lifting, HULK Metal’s Ring Clutch ensures reliable, stable, and secure lifting performance.

Types:

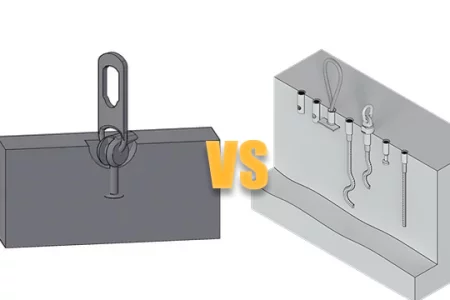

Ring Clutch:

The Ring Clutch is engineered for lifting precast concrete elements with Spread Anchors. Produced with precision casting, forging, and welding, it guarantees high strength, stable performance, and safe handling in demanding construction environments with CE and ISO 9001 certification.

Cable Ring Clutch:

The Cable Ring Clutch is designed for lifting precast concrete elements securely with spread anchors. Manufactured by precision casting and hot forging, it provides strong performance, durability, and safe operation. Each clutch meets international standards and offers consistent reliability in heavy-duty lifting.

Ring Clutch Lifting Device Features:

Highly Flexible Operation

Its freely rotating shackle structure allows for smoother connection, adjustment, and positioning, suitable for multi-directional and multi-angle lifting scenarios, improving overall operational efficiency.

More Reliable Safety Locking Structure

The lifting head with locking pins can quickly and safely connect to pre-embedded anchors, reducing the risk of misoperation and ensuring stability and reliability under heavy loads.

Superior Material Strength

The lifting head, forged locking pins, and lifting rings are all made of high-strength alloy steel or quenched and tempered cast steel, possessing higher tensile strength, wear resistance, and fatigue resistance.

Visual Inspection of Welding Quality

The hook area undergoes deep welding, and the weld integrity is verified through X-ray inspection, ensuring stable performance during high-frequency lifting.

Meets Stringent Safety Standards

HULK Metal's Ring Clutch has a five-fold safety factor, fully complying with the "Safety Code for Lifting Precast Concrete Components," suitable for heavy-duty construction, factory lifting, and installation of large precast components.

High compatibility & easy replacement

Compatible with multiple types of spread anchors, quick replacement without complicated tools, improving construction continuity and on-site management efficiency.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Ring Clutch Lifting Device Application and Installation:

Application:

The Ring Clutch is widely used in the lifting, handling, and installation of precast concrete elements across various construction environments. It is ideal for panels, beams, columns, stair units, solid walls, hollow-core components, and other heavy precast structures requiring secure anchoring and controlled lifting. Its flexible shackle design allows multi-directional load engagement, making it suitable for complex site conditions and angled lifting operations. The device is commonly applied in precast factories, infrastructure projects, building construction, bridge components, and modular construction fields. With high strength, reliable locking, and compliance with safety standards, the Ring Clutch ensures stable and efficient lifting throughout the entire precast workflow.

Lifting Clutch Lifting Device Production Process

The production of a Ring Clutch Lifting Device follows a strict, engineering-grade manufacturing workflow to ensure strength, reliability, and compliance with international lifting standards.

Raw Material Selection

High-strength alloy steel is selected for the lifting head, forged bolt, and shackle. All materials undergo chemical composition analysis to ensure consistent mechanical properties and traceability.

Forging of Critical Components

The lifting head and locking bolt are precision-forged to achieve superior density, structural integrity, and fatigue resistance. Forging also enhances impact performance required for heavy precast lifting.

CNC Machining & Dimension Control

All forged parts are CNC-machined to precise tolerances. The connecting surfaces, bolt holes, and locking mechanisms are finished to ensure smooth engagement with precast anchors.

Welding of Hook Components

The lifting hook is welded with thickened structural steel using certified welding procedures. Each weld must meet deep-penetration requirements and is verified through X-ray inspection to ensure zero internal defects.

Heat Treatment & Hardening

The bail and other major components are hardened and tempered to achieve the required balance of strength, toughness, and wear resistance. This process ensures stable performance under dynamic lifting loads.

Assembly & Mechanical Testing

Shackles, bolts, hooks, and lifting heads are assembled and tested for smooth rotation, secure locking, and correct anchor engagement. The device undergoes load tests to verify its rated capacity.

Surface Treatment

Components receive protective coatings such as galvanizing or painting to enhance corrosion resistance and extend service life, especially for outdoor or long-term construction environments.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Ring Clutch Lifting Device Quality Inspection:

Ring Clutch Lifting Device Quality Inspection

The quality inspection of a Ring Clutch Lifting Device follows a strict, multi-stage control system to ensure every unit meets high safety and performance standards for precast concrete lifting.

Raw Material Verification

All alloy steel materials undergo chemical composition testing, hardness checks, and certification review before entering production, ensuring the required strength and consistency.

Forging Integrity Inspection

Forged lifting heads and bolts are tested for internal defects through ultrasonic or magnetic particle inspection. This guarantees dense structure, high toughness, and superior fatigue resistance.

Dimensional and Tolerance Check

CNC-machined parts are measured with precision instruments to confirm exact tolerances, ensuring smooth engagement with anchors and reliable locking performance.

Welding Examination with X-Ray Testing

The hook welding undergoes deep-penetration requirements and is inspected using X-ray equipment to detect hidden cracks, pores, or fusion defects, ensuring maximum structural reliability.

Heat Treatment Validation

Hardness and microstructure tests are performed after quenching and tempering to verify proper strength, ductility, and load-bearing consistency.

Functional Testing

Each assembled clutch is checked for smooth shackle rotation, accurate bolt locking, and secure anchor connection. Functional durability tests simulate real working conditions.

Load Testing

Every batch is subjected to proof-load testing—typically at 1.5× the rated load—to ensure the device performs safely under extreme lifting conditions.

Surface Protection Check

Coating adhesion, corrosion resistance, and surface uniformity are inspected to ensure long-term durability in harsh construction environments.

Final Safety and Certification Review

Each Ring Clutch is labeled with traceable identification and approved only after passing all safety standards, including those specified in Safety Regulations for Lifting Precast Concrete Units.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable Ring Clutch Lifting Device:

Higher Quality with Lower Risk:

Enhanced material control, strict forging inspection, and full-load testing ensure stable performance, reduce lifting failures, and significantly minimize operational risk in demanding precast concrete handling environments.

Effective Cost Management:

Optimized production flow, precise machining, and efficient resource allocation help reduce unnecessary waste, improve overall productivity, and deliver high-value lifting solutions with competitive and predictable project costs.

Strengthen Brand Reputation:

Consistently reliable products, certified safety compliance, and responsive technical support enhance customer trust, elevate market recognition, and reinforce your brand’s long-term credibility within the precast construction industry.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Concrete Accessories You Might Want to Know

Besides Lifting Clutch, we also provide Precast Magnets, Spread Anchors, Spherical Head Lifting Anchors, Lifting Sockets, and Recess Formers. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Ring Clutch Lifting Device in Blogs

Here is the introduction, production, and quality inspection of Lifting Ring Clutch that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a message if you want to share or get some content about Lifting Ring Clutch.

-

June 20, 2025Lifting Sockets vs Lifting Anchors: Which Is Better for Precast Concrete?

June 20, 2025Lifting Sockets vs Lifting Anchors: Which Is Better for Precast Concrete?Precast concrete has become one of the key materials in modern construction. Whether you are working on large infrastructure projects or building residential developments, using precast concrete components can significantly improve efficiency, consistency, and safety on-site.

-

February 08, 2025Lifting Clutch and Ring Clutch: Key equipment to ensure the safety and efficiency of lifting operations

February 08, 2025Lifting Clutch and Ring Clutch: Key equipment to ensure the safety and efficiency of lifting operationsIn modern construction, manufacturing, and transportation industries, lifting operations are an integral part of daily operations. Whether it is transporting heavy machinery, hoisting precast concrete components, or handling large equipment, choosing the right lifting equipment is essential to ensure safe operations and improve work efficiency.

-

August 31, 2023Guide to clutch Maintenance and Care: Ensuring Safe and Efficient Operations

August 31, 2023Guide to clutch Maintenance and Care: Ensuring Safe and Efficient Operationsclutches are indispensable equipment in industrial production, responsible for crucial tasks such as material handling and lifting.

-

August 29, 2023How to maintain the shuttering magnet in the application of precast concrete?

August 29, 2023How to maintain the shuttering magnet in the application of precast concrete?In the realm of prefabricated concrete structures, the fixed magnetic box stands as a crucial connecting element, employed to secure molds or templates in their designated positions prior to concrete casting.

-

August 24, 2023Precast Concrete Accessories: Advantages and Modern Applications

August 24, 2023Precast Concrete Accessories: Advantages and Modern ApplicationsAs an expert in precast concrete accessories, I will provide you with a comprehensive overview of the concept, benefits, and contemporary applications of these components.

Reviews

-

Stewen

The Ring Clutch Lifting Device delivers exceptional strength, secure engagement, and reliable performance, greatly improving our precast lifting efficiency and safety.