Precast Concrete Lifting Lugs

Description:

HULK Metal’s Precast Concrete Lifting Lugs are built to provide safe, efficient, and reliable handling of precast components. Produced with high-grade 35CrMoV special casting head clutch and forged bolt. Also known as lifting clutches or dog bone lifting eyes, they are engineered to work with lifting anchors, ensuring secure lifting and easy installation. When the head of the lifting clutch is inserted into the recess and anchor head, the bolt will lock down the anchor from the head of the lifting clutch.Every piece undergoes strict quality testing to comply with global safety standards, giving construction teams confidence on-site. Suitable for panels, slabs, beams, and other precast elements, HULK Metal’s lifting lugs improve job-site efficiency, minimize risks, and offer long-lasting performance. Their strength and reliability make them a preferred solution for demanding lifting applications worldwide.

Parameters of HULK Metal Precast Concrete Lifting Lugs:

| NAME | MATERIAL | Q345D / Q355D / CM490 / G30CrMoV / Customizable | ||

| Concrete Panel Lifters | SURFACE TREATMENT | Electro-galvanized | ||

| SAFETY FACTOR | ≥ 5 | |||

| CERTIFICATE | ISO9001 / CE | |||

| SWL (tons) | CODE | LENGTH(mm) | WEIGHT(kg/pc) | |

| 1.3 | HM-PC-013 | 165 | 1.0 |

| 2.5 | HM-PC-025 | 205 | 1.7 | |

| 5.0 | HM-PC-050 | 240 | 3.6 | |

| 10.0 | HM-PC-100 | 346 | 9.8 | |

| 20.0 | HM-PC-200 | 520 | 24.5 | |

| 32.0 | HM-PC-320 | 590 | 45.0 | |

Features About Precast Concrete Lifting Lugs:

-

Higher Quality Precast Concrete Lifting Lugs:

Precast Concrete Lifting Lugs Introduction

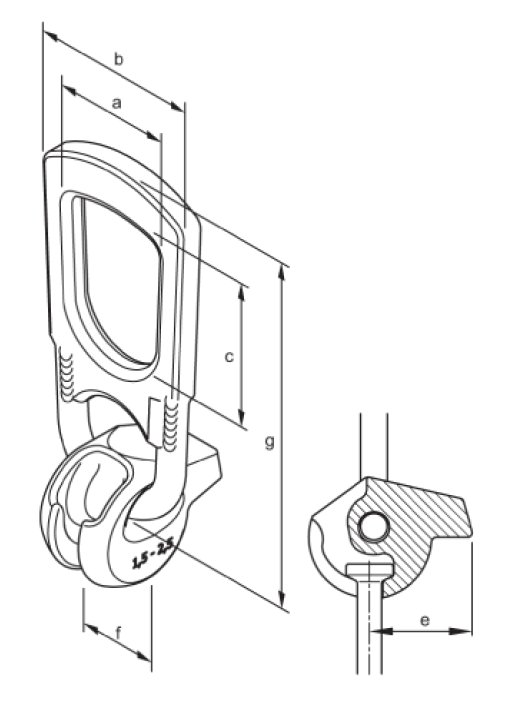

Precast Concrete Lifting Lugs, also called Concrete Panel Lifters, lifting clutch, Spherical Head Lifting Clutch, Dog Bone lifting clutch, and lifting eyes. The Precast Concrete Lifting Lugs feature a durable body with a projecting lever arm and reinforced bail, with a “T” slot that locks securely into the head of a DogBone Anchor. This design ensures reliable lifting, tilting, and rotation of precast concrete panels under heavy loads.

Craftsmanship

HULK Metal’s Precast Concrete Lifting Lugs are crafted using advanced casting, forging, and welding processes to ensure maximum reliability in precast lifting applications.

Casting Head Clutch: Precisely cast for consistent dimensions and high mechanical strength, providing secure engagement with lifting anchors.

Forged Bolt: Crafted through forging to enhance toughness and load-bearing capacity, ensuring long-term durability under heavy stress.

Welded Head Clutch and Bolt: Deep-penetration welding guarantees seamless strength and safe load transfer. Every weld is rigorously tested, including X-ray inspection, delivering unmatched safety and performance for demanding precast projects.

System Components

Lifting Anchor

Lifting anchors are core connection points embedded within precast concrete components. They provide a secure connection for lifting equipment, ensuring safe and stable handling of panels, beams, and other precast components. Made of high-strength steel with a triple safety factor, these anchors are durable, provide a precise fit, and ensure reliable load transfer during lifting operations.

Recess Former

The recess former forms a precise recess in the concrete for the lifting anchor. It ensures the anchor is properly and securely seated, facilitating the installation of lifting lugs. Its flexible and resilient material protects the concrete surface while maintaining the precise shape required for optimal anchor engagement, making it reusable.

Precast Concrete Lifting Lugs

These lifting lugs are designed to connect directly to the lifting anchor, enabling the safe lifting, tilting, or rotation of precast components. Made of high-strength steel and utilizing advanced manufacturing processes such as casting, forging, and welding, Precast Concrete Lifting Lugs offer exceptional load-bearing capacity, durability, and long-term reliability. Each lifting lug has been rigorously tested and complies with international safety standards, ensuring peace of mind with every lift.

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Precast Concrete Lifting Lugs with Shorter Lead Time:

How to Lift a Precast Panel Using a Precast Concrete Lifting Lug and Lifting Anchor

1. Position the precast lifting clutch over the embedded lifting anchor, aligning the clutch slot with the anchor head. Rotate the clutch until its tab rests firmly against the surface of the concrete.

2. Begin lifting slowly, allowing the anchor to fully absorb the applied tension.

3. As the panel moves into a vertical orientation, the clutch engages the concrete surface, transferring the lifting force safely while the anchor prevents any unintended displacement.

4. Lifting from the tab remains secure as long as the tab does not exceed an angle of 30° relative to the concrete surface, ensuring stable and controlled handling throughout the operation.

Precast Concrete Lifting Lugs Periodic Inspection Guide

1. Weekly Visual Inspection

Inspect the lifting lug surface for cracks, deformation, rust, or weld defects.

Confirm that welds and cast areas are free of visible damage or spalling.

Inspect bolts, pins, and connecting components for loose or missing parts.

2. Monthly Measurement and Verification

Use a gauge to measure the lifting lug dimensions to ensure they conform to design specifications.

Check the fit of the "head" or socket with the precast anchor to ensure there is no excessive play.

3. Quarterly Load Testing

Test the lifting lug with a light load or full load (depending on frequency of use and specifications).

Inspect for abnormal deformation or slippage under load.

4. Semi-Annual Cleaning and Protection

Clean the lifting lug surface from concrete residue, dust, or corrosion.

Apply rust inhibitor according to environmental conditions to prevent steel corrosion.

5. Ongoing Recordkeeping and Maintenance

Maintain detailed inspection records, noting inspection dates, any defects found, and any corrective actions.

Any damage or abnormality found must be replaced or repaired immediately and no further use is allowed.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Precast Concrete Lifting Lugs with Better Service:

HULK Metal's Production Capabilities

HULK Metal has a complete set of molds for Precast concrete lifting lugs, enabling the production of full-size lifting lugs. We also own our own forging and casting equipment, enabling us to independently manufacture our Precast concrete lifting lugs from raw materials to finished product, improving production efficiency.

Quality Inspection Services

Throughout the production and completion of our Precast concrete lifting lugs, we conduct material, dimensional, strength, and load tests, and issue inspection reports. All inspection processes are carefully documented, and we ultimately issue authoritative inspection reports, providing customers with traceable quality assurance and peace of mind for construction teams.

After-Sales Service

Delivery is just the beginning of our partnership, and HULK Metal's service doesn't end there. We provide every customer with ongoing technical support and guidance to ensure the stable and safe performance of our Precast Concrete Lifting Lugs during construction. Whether it's installation or application issues, or ongoing maintenance needs, our team will promptly respond and provide professional solutions. We also conduct regular follow-up visits to collect customer feedback for continuous product and service optimization.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable Precast Concrete Lifting Lugs:

Higher Quality

HULK Metal ensures every Precast Concrete Lifting Lug meets strict international standards. Through advanced forging, casting, and welding processes, combined with rigorous testing, we guarantee products with exceptional strength, durability, and safety for the most demanding construction applications worldwide.

All-Round Cost Control

With in-house forging, casting, and machining facilities, HULK Metal controls every production stage. This integrated approach reduces outsourcing costs, optimizes efficiency, and ensures competitive pricing—helping clients achieve reliable quality without sacrificing budget or project profitability.

Shaping Your Brand Image

By delivering safe, durable, and certified lifting solutions, HULK Metal helps enhance your brand reputation. Consistently reliable products strengthen trust with clients and stakeholders, showcasing your commitment to quality, professionalism, and long-term project success.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Precast Concrete Lifting Lugs You Might Want to Know

Besides Precast Concrete Lifting Lugs, we also provide Spherical Head Lifting Anchors, Lifting Clutch For Concrete, and Recess Formers For Lifting Anchors. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Concrete Panel Lifters in Blogs

Here is the introduction, production, and quality inspection of concrete panel lifters that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a message if you want to share or get some content about concrete panel lifters.

-

August 20, 2025Selecting the Right Lifting Accessory for Different Precast Applications

August 20, 2025Selecting the Right Lifting Accessory for Different Precast ApplicationsThe efficiency and safety of precast concrete installation depend not only on the precision of the concrete elements themselves but also on the lifting systems used to handle them. Every precast unit—whether it is a wall panel, a structural beam, or a compact architectural detail—requires the correct lifting accessory to ensure secure handling and minimize risks during transport and installation.

-

August 12, 2025Everything You Need to Know About Lifting Anchor Systems

August 12, 2025Everything You Need to Know About Lifting Anchor SystemsIn the precast concrete industry, details determine success or failure—especially when it comes to lifting and handling heavy components. Whether installing wall panels, beams, columns, or bridge sections, you need reliable equipment. One of the most important tools is the lifting anchor system.

-

August 06, 2025ISO Certified Precast Concrete Accessories Factory in China

August 06, 2025ISO Certified Precast Concrete Accessories Factory in ChinaWhen it comes to sourcing precast concrete accessories, finding a reliable, high-quality manufacturer is everything. From lifting sockets and wire loop boxes to spread anchors and cast-in channels, your project’s structural integrity depends on the components you choose.

-

June 26, 2025How Lifting Anchors, Lifting Clutches, and Recess Formers Work Together in Precast Lifting

June 26, 2025How Lifting Anchors, Lifting Clutches, and Recess Formers Work Together in Precast LiftingPrecast concrete construction is a rapidly growing solution in modern infrastructure due to its speed, quality, and efficiency. However, lifting and placing heavy concrete components require more than just raw power—it requires precision, safety, and well-matched accessories.

Reviews

-

Joaquin Zimmerman

HULK Metal’s precast concrete lifting lugs are durable, easy to use, and extremely reliable. They made our lifting work safer, faster, and highly efficient.