concrete panel lifters

Description:

Concrete panel lifters are essential devices designed to provide safe, efficient, and reliable handling of precast concrete elements. Engineered with precision, these lifters connect with lifting anchors, allowing panels to be lifted, rotated, or tilted with full stability during installation. Concrete panel lifters are manufactured using advanced forging and casting processes and are fully CE-compliant. Each lifter features a custom-cast clutch head made of high-quality 35CrMoV steel and precision-forged bolts, ensuring exceptional strength and durability. Each product undergoes 100% magnetic particle inspection to ensure reliability, and a 5:1 safety factor provides maximum safety during lifting operations.

Parameters of HULK Metal Concrete Panel Lifters:

| NAME | MATERIAL | Q345D / Q355D / CM490 / G30CrMoV / Customizable | ||

| Concrete Panel Lifters | SURFACE TREATMENT | Electro-galvanized | ||

| SAFETY FACTOR | ≥ 5 | |||

| CERTIFICATE | ISO9001 / CE | |||

| SWL (tons) | CODE | LENGTH(mm) | WEIGHT(kg/pc) | |

| 1.3 | HM-PC-013 | 165 | 1.0 |

| 2.5 | HM-PC-025 | 205 | 1.7 | |

| 5.0 | HM-PC-050 | 240 | 3.6 | |

| 10.0 | HM-PC-100 | 346 | 9.8 | |

| 20.0 | HM-PC-200 | 520 | 24.5 | |

| 32.0 | HM-PC-320 | 590 | 45.0 | |

Features About Concrete Panel Lifters:

-

Higher Quality Concrete Panel Lifters:

Concrete Panel Lifters Introduction

Concrete Panel Lifters,also called lifting clutch, Spherical Head Lifting Clutch

Materials

Concrete Panel Lifters are made of Q345D/Q355D/CM490/G30CrMoV materials and can be customized according to customer requirements.

Surface Treatment

They feature electroplated galvanizing for surface protection.

Safety Factor

They offer a 5:1 safety factor. HULK Metal labels each Concrete Panel Lifter with its brand (according to customer requirements), specifications, working load limit, and batch number for traceability and operator convenience. Customization is available to meet specific project requirements.

Size

Choose from six sizes, ranging from 1.3t to 32t, to meet the requirements of various lifting environments.

Concrete Panel Lifters are CE certified and compliant with standards.

The combined rotation capabilities of the main body and the bail allow a precast panel to be lifted, turned, tilted, and/or rotated while under load.

Identification

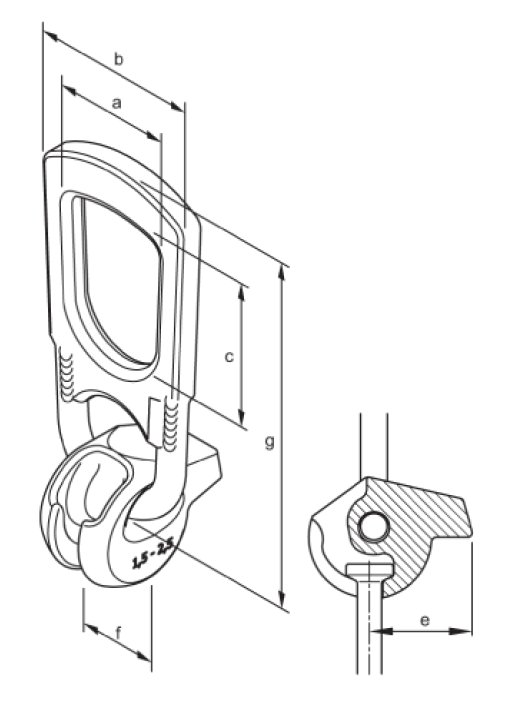

The concrete panel lifter is an attachment link for the lifting and transporting of precast concrete units in combination with the Spherical Head Anchor. The concrete panel lifter is manually operated and manufactured in the versions given in the following table. The allowable loads for individual cases must be checked using the tables for each anchor type.

Safety regulations in the country of use must always be observed, in particular those for the use of cranes and lifting equipment.

The customer must ensure that the concrete panel lifters are checked for any damage before use. In addition, the customer must carry out full inspections at regular intervals. These must be carried out by a qualified person at intervals to suit the site conditions or, in any event, every year.

Reject the clutch if:

• it is deformed/bent in any way.

• It is worn such that max h and min m are exceeded.

• The identification lettering is worn away.

Inspections must be recorded in a report showing the values measured. Records must be filed and stored in an appropriate place. As a guide, experience has shown that links last approximately 7 years. Alterations and repairs to the Universal Heads, especially welding operations, are strictly forbidden.

You can get free samples to check whether they can meet the requirements.Get Free Samples

You can get free samples to check whether they can meet the requirements.Get Free Samples -

Concrete Panel Lifters with Shorter Lead Time:

Operating the Concrete Panel Lifters

Coupling:

1. Check the load duty of the anchor

2 . To connect the lifting link to the anchor, the sphere is pushed with its opening facing downwards over the anchor.

3. The tongue of the sphere is then turned downwards to close around the anchor. The Universal Head sits in the recess and is now ready for use

Lifting:

The Concrete Panel Lifter is suitable for axial loads and pitching. The unit can also be rotated on the lifting link when pitching the unit. The tongue must be closed during this process. The counterweight of the tongue ensures that the sphere remains in the correct position, even when the load is released. Turning the link while under load is restricted by friction. A small amount of grease is allowed if necessary.

Release:

When the load is taken off, release the lifting clutch by turning the sphere with the tongue as shown. Lift the lifting clutch well away, and do not let it dangle over the anchor.

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution

You can get a solution with shorter order delivery times and guaranteed quality and quantity.Get Your Free Solution -

Concrete Panel Lifters with Better Service:

HULK Metal's Production Capabilities

HULK Metal possesses advanced forging and CNC machining equipment, enabling us to independently manufacture and manufacture Concrete Panel Lifters, from mold making and forging to precision machining. With just one stroke, both the head and foot are forged, even for double heads, with exceptional precision.

Quality Assurance Services

HULK Metal adheres to strict quality control standards at every stage of production. Our Concrete Panel Lifters undergo multiple tests, including dimensional, tensile, and surface quality testing, to ensure full compliance with international standards. Customers can rest assured knowing that we always adhere to the principle of "quality first" and provide truly reliable products.

HULK Metal's laboratory can perform the following tests on metal products:

Tensile/proof load testing, impact testing, metallographic testing, balance testing, temperature control testing, UV spectrophotometry testing, dimensional testing, appearance testing, salt spray testing, mechanical testing, tolerance analysis, tool life analysis, hardness testing, ASTM-compliant hot-dip galvanizing thickness testing, roughness testing, and OEM packaging.

Many tests are mandatory before shipment. We can provide various tests and reports tailored to individual customer needs.

After-Sales Service

After-sales service is as important as product quality. We understand that customers may have various technical or practical questions after receiving our products. HULK Metal provides comprehensive after-sales service, rapid response, and comprehensive support. Our high-quality after-sales service ensures that customers receive more than just the product; it provides ongoing assurance and trust.

You can benefit from the comprehensive services of a dedicated client team.Contact Your Dedicated Service Team -

Cost-controllable Concrete Panel Lifters:

Higher Quality & Controllable Cost

We always prioritize high quality. Through advanced craftsmanship and rigorous quality inspection processes, we ensure that every concrete panel lifter is reliable and durable. We also optimize costs throughout the production process, ensuring customers receive higher-quality products at reasonable prices, achieving a balance between quality and cost.

All-Round Cost Control

Throughout the entire supply chain, we achieve comprehensive cost control through centralized procurement, intelligent production management, and an efficient logistics system. This not only helps customers reduce unnecessary expenses but also shortens delivery cycles, ensuring products maintain competitiveness while delivering higher value.

Shaping Your Brand Image

High-quality products and a stable supply chain help customers establish a trustworthy brand image. We not only provide sturdy and reliable concrete panel lifters, but also offer integrated solutions, making customers' products more competitive in the market and earning greater customer recognition and trust.

You can leave a request and get a more suitable quotation.Get a Better Quotation

Procurement Process

-

01In-depth understanding of your requirement.

-

02In-depth understanding of your requirement.

-

03In-depth understanding of your requirement.

-

04In-depth understanding of your requirement.

-

05In-depth understanding of your requirement.

-

09In-depth understanding of your requirement.

-

08In-depth understanding of your requirement.

-

07In-depth understanding of your requirement.

-

06In-depth understanding of your requirement.

Other Lifting Clutch You Might Want to Know

Besides Concrete Panel Lifters, we also provide Spherical Head Lifting Anchors, Lifting Clutch For Concrete, and Recess Formers For Lifting Anchors. You can click on the corresponding picture for details. We will provide you with a full range of production services, and you can rest assured to place your order with us.

You Can Know About Concrete Panel Lifters in Blogs

Here is the introduction, production, and quality inspection of concrete panel lifters that we can organize, as well as some sharing from customers and details of our delivery. You can leave us a message if you want to share or get some content about concrete panel lifters.

-

August 20, 2025Selecting the Right Lifting Accessory for Different Precast Applications

August 20, 2025Selecting the Right Lifting Accessory for Different Precast ApplicationsThe efficiency and safety of precast concrete installation depend not only on the precision of the concrete elements themselves but also on the lifting systems used to handle them. Every precast unit—whether it is a wall panel, a structural beam, or a compact architectural detail—requires the correct lifting accessory to ensure secure handling and minimize risks during transport and installation.

-

August 12, 2025Everything You Need to Know About Lifting Anchor Systems

August 12, 2025Everything You Need to Know About Lifting Anchor SystemsIn the precast concrete industry, details determine success or failure—especially when it comes to lifting and handling heavy components. Whether installing wall panels, beams, columns, or bridge sections, you need reliable equipment. One of the most important tools is the lifting anchor system.

-

August 06, 2025ISO Certified Precast Concrete Accessories Factory in China

August 06, 2025ISO Certified Precast Concrete Accessories Factory in ChinaWhen it comes to sourcing precast concrete accessories, finding a reliable, high-quality manufacturer is everything. From lifting sockets and wire loop boxes to spread anchors and cast-in channels, your project’s structural integrity depends on the components you choose.

-

June 26, 2025How Lifting Anchors, Lifting Clutches, and Recess Formers Work Together in Precast Lifting

June 26, 2025How Lifting Anchors, Lifting Clutches, and Recess Formers Work Together in Precast LiftingPrecast concrete construction is a rapidly growing solution in modern infrastructure due to its speed, quality, and efficiency. However, lifting and placing heavy concrete components require more than just raw power—it requires precision, safety, and well-matched accessories.

Reviews

-

Leona Hawkins

These concrete panel lifters are durable, safe, and easy to use. Excellent quality with reliable performance for precast handling.